Quality control is an essential part of any manufacturing process. Whether it's inspecting parts, measuring dimensions, or simply verifying assembly, consistent checks at every step help maintain product standards and reduce errors.

Odoo 18 simplifies this process with its Quality and Manufacturing modules. One powerful feature is the ability to set Quality Control Points (QCPs) on specific Work Order Operations. This means you can trigger a quality check automatically at any step during the production process.

In this blog, we’ll guide you through setting a Quality Control Point on Work Order Operations in Odoo 18 using the functional interface, ideal for manufacturing users and quality managers who want to ensure every product meets expectations.

Before getting started with quality control points, ensure that both the Manufacturing and Quality modules are installed from the Odoo Apps menu.

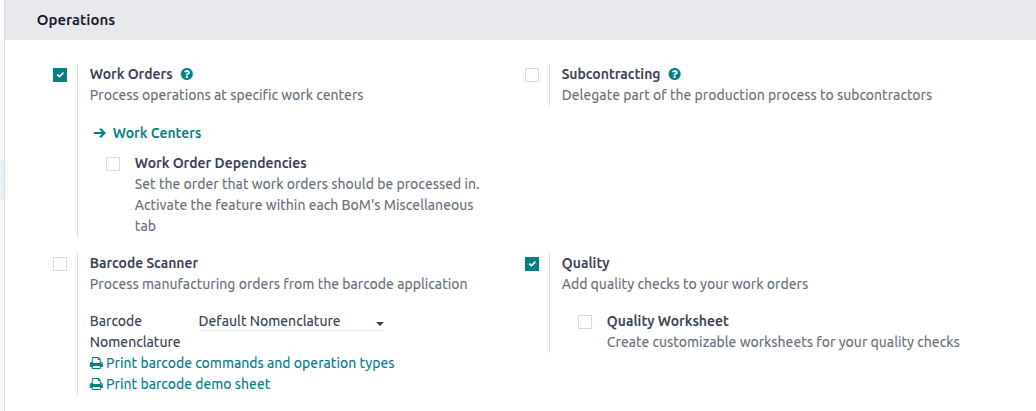

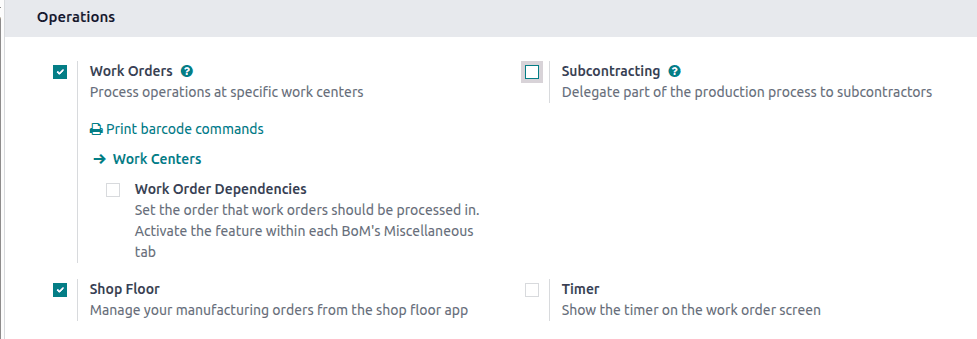

Once installed, navigate to Manufacturing > Configuration > Settings, and enable both the Work Orders and Quality options.

This step is important as work orders break down the manufacturing order into step-by-step operations, and the quality module integrates checkpoints into those steps.

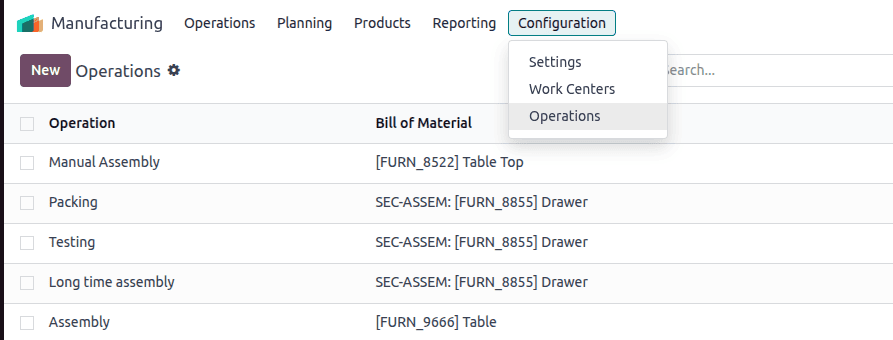

Once Work Orders and Quality are enabled, you can define the individual operations that will make up your production process. These are accessible via:

Manufacturing > Configuration > Operations

The next step is to define the individual operations that make up your production process.

Each operation, such as Cutting, Welding, or Painting, represents a specific task that will later appear as a separate work order during the actual production run.

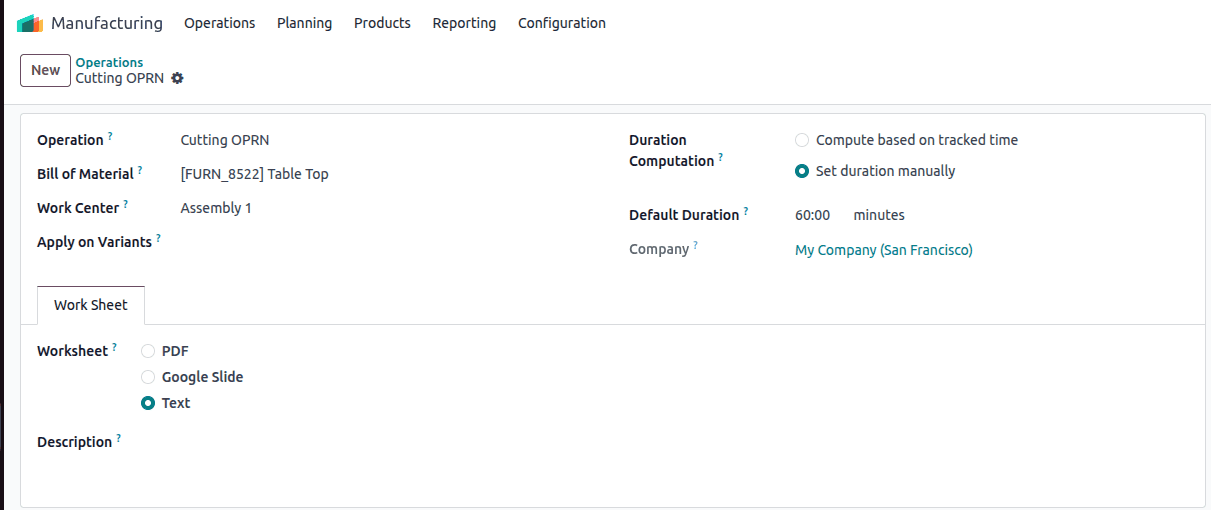

Click New to define a new operation, this represents a step such as Cutting, Welding, or Painting in the manufacturing workflow.

While creating the operation, make sure to link it with an existing Bill of Materials (BoM) using the “Bill of Material” field. This ensures the operation is included in the manufacturing flow and is converted into a Work Order when the BoM is used. Specify other necessary details such as the Operation Name, Work Center, Default Duration, and optionally Apply on Variants if needed.

Although this guide showcases the creation of a single operation as an example, make sure to create the remaining operations that form your complete production sequence, each linked to the same BoM product. This will allow you to assign Quality Control Points to all stages of the manufacturing process.

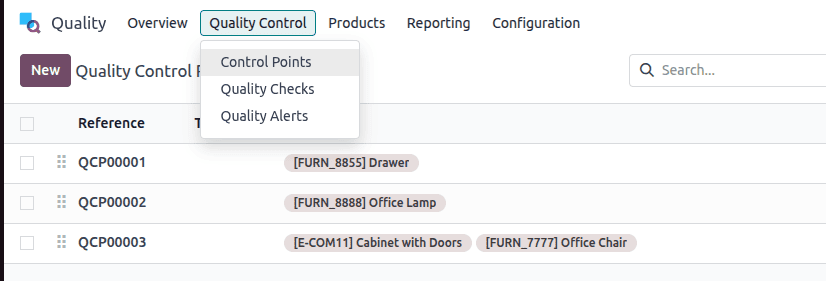

Now that your operations are linked to a BoM, the next step is to introduce quality checks at critical stages using Quality Control Points. These are configured within the Quality module.

To ensure that quality checks are seamlessly integrated into your manufacturing process, it’s important to configure Quality Control Points (QCPs) properly. These checkpoints act as control gates during specific operations (e.g., Cutting, Welding) and are made visible within the Shop Floor module interface.

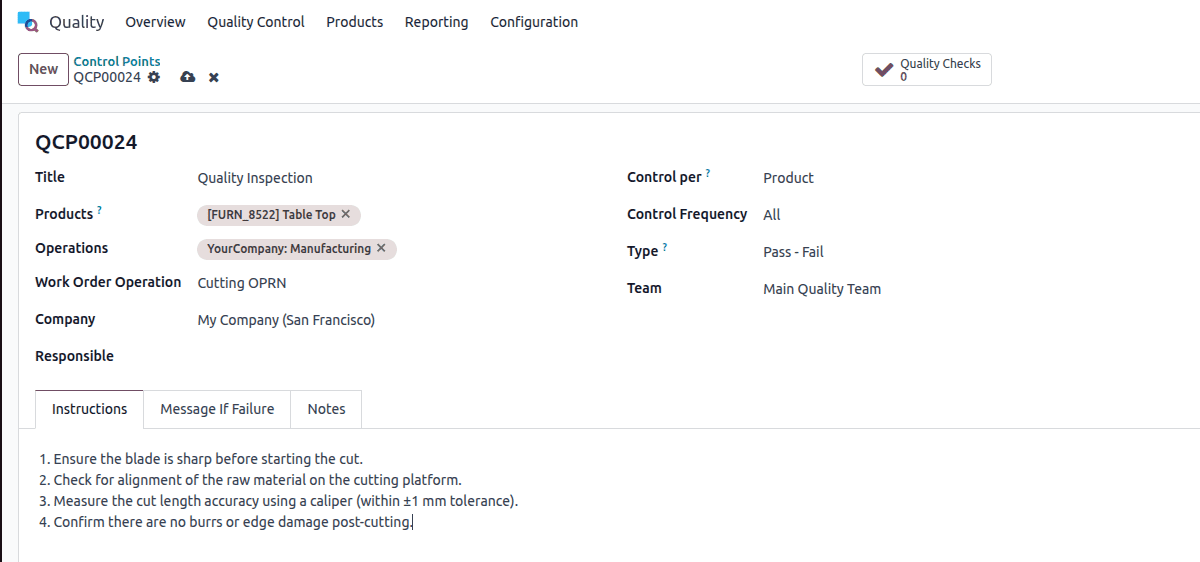

Navigate to Quality > Quality Control > Control Points, and click on New to create one.

Begin by entering a suitable Title that clearly describes the purpose of the quality check. In the Products field, you can specify a particular product to which the check applies. Alternatively, you may use Product Categories if the check is relevant for multiple products under a shared category.

Under the Operations field, select the relevant type of operation depending on when you want the control point to be triggered.

You can also define how often the check should occur using the Control per option, whether it's for every product, once per operation, or after a specified quantity. Additionally, set the Control Frequency to determine if the check should happen for all items, randomly, periodically, or on demand. Assign a responsible person and team, and ensure the correct company is selected.

To make the quality check effective, write clear and specific instructions under the “Instructions” field. This ensures that the operator on the shop floor understands what is expected.

Once saved, this control point will automatically be triggered at the defined stage in your process, enabling structured and consistent quality checks throughout manufacturing.

Once you've successfully configured the Quality Control Point for a specific operation and product in our example, the Table Top, it's time to test whether everything functions as expected.

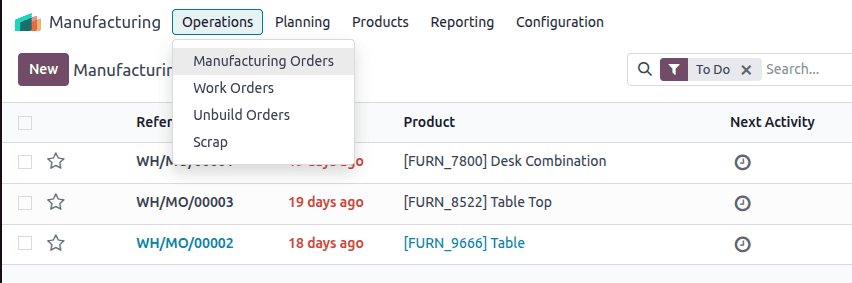

To do this, navigate to the Manufacturing module and create a new Manufacturing Order (MO) for the same product you used while setting up the BoM and QCP (in this case, Table Top).

The next step is to validate its functionality through a Manufacturing Order (MO).

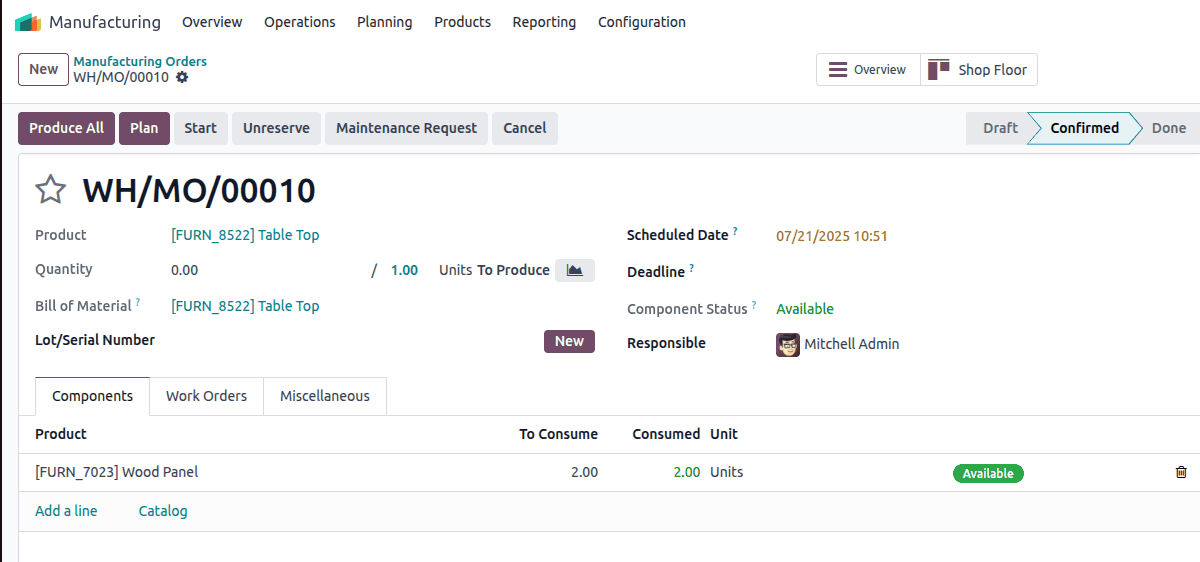

Here, you’ll enter the key details of your Manufacturing Order (MO). First, select the Product you wish to produce, this represents the final item that will come out of the production line. Then, specify the quantity you plan to manufacture. Next, choose the appropriate Bill of Materials (BoM), which should already include the necessary routing steps and work center operations such as Cutting, Welding, or Assembly. Finally, set the Scheduled Date, the intended start date for production.

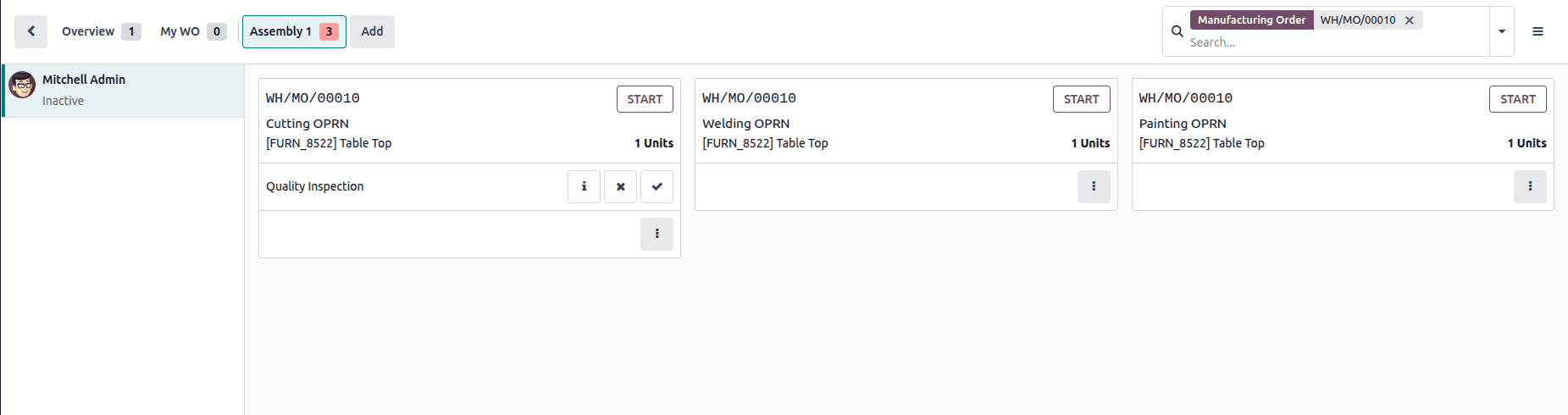

Once your Manufacturing Order (MO) is confirmed, Odoo automatically generates the relevant Work Orders based on the routing steps defined in the Bill of Materials (BoM). These could include operations like Cutting, Welding, or Painting, depending on your workflow.

To process these work orders in an intuitive and operator-friendly environment, navigate to the Shop Floor interface by clicking the Shop Floor smart button from the MO.

Make sure the Shop Floor module is installed and enabled in the Manufacturing module’s configuration settings to access this functionality.

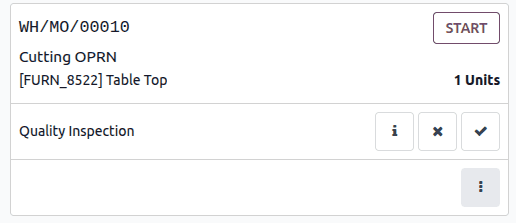

The Shop Floor interface presents each operation as a separate, visually organized card, each with a Start button. If you've linked Quality Control Points (QCPs) to a specific operation (like Cutting), a Quality Inspection prompt appears directly within the work order card before the operation can begin.

To proceed, click the Start button on the operation card. This signals that the operator has begun work on that step.

If the operation is linked with a Quality Control Point (QCP), the system will prompt a Quality Check before allowing the task to proceed. The operator will be required to either pass or fail the check based on predefined criteria.

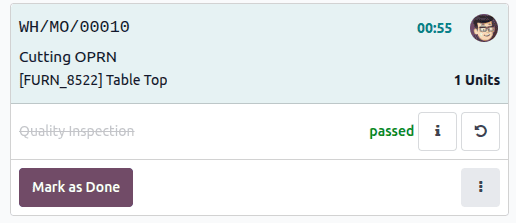

As shown in the screenshot above, once the Start button is clicked and the operation is underway, the interface updates in real-time, displaying the elapsed time at the top right and the user profile who initiated the task.

In this example, the operation is Cutting OPRN for the component [FURN_8522] Table Top, with a quantity of 1 Unit. Since a Quality Inspection was linked to this step, it was triggered automatically. After the inspection was conducted, the status is clearly shown as “passed” in green, ensuring quality compliance before proceeding further.

Once the task is completed, the operator can click the “Mark as Done” button. This action logs the completion, enabling the next operation in the routing (if any) to be performed, and ensures smooth traceability and workflow continuity. At the last operation, we can close the production.

Odoo 18 makes quality control effortless by letting you attach Quality Control Points (QCPs) directly to specific work order operations. From setting templates to tracking execution via the Shop Floor interface, everything is seamlessly connected. This ensures your production remains consistent, compliant, and efficient. With real-time checks and visual cues, you get full control over quality at every stage. Ready to level up your manufacturing game? Odoo’s got you covered.

To read more about How can we set Quality Control Point On Operation Types in Odoo 18, refer to our blog How can we set Quality Control Point On Operation Types in Odoo 18.