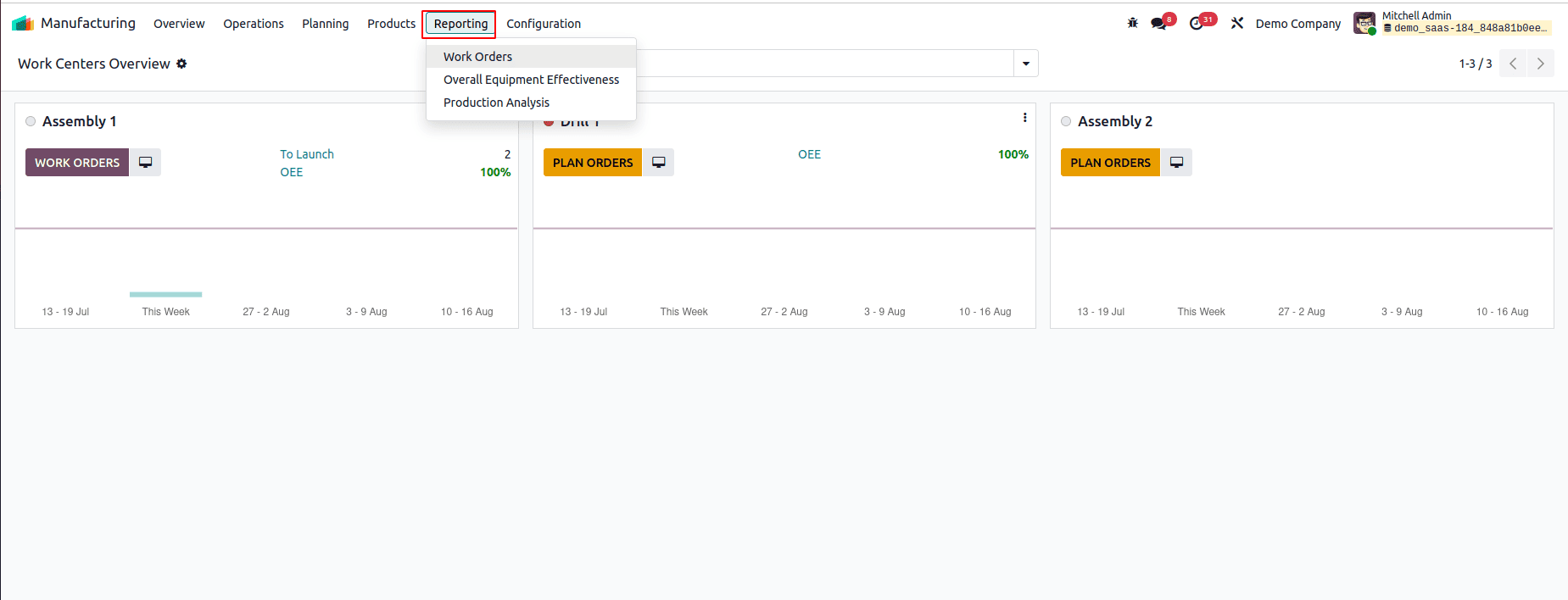

Odoo 18 offers a powerful Reporting feature within the Manufacturing module, enabling users to analyze and monitor various aspects of their production processes. This functionality provides valuable insights into operations carried out over a specific timeframe, helping businesses make informed decisions. Under the Reporting menu, users can access detailed reports such as Work Orders, Manufacturing Orders, Production Analysis, and Overall Equipment Effectiveness (OEE). These reports present key data that highlight productivity, equipment performance, and process efficiency, supporting continuous improvement in manufacturing operations.

Work Orders

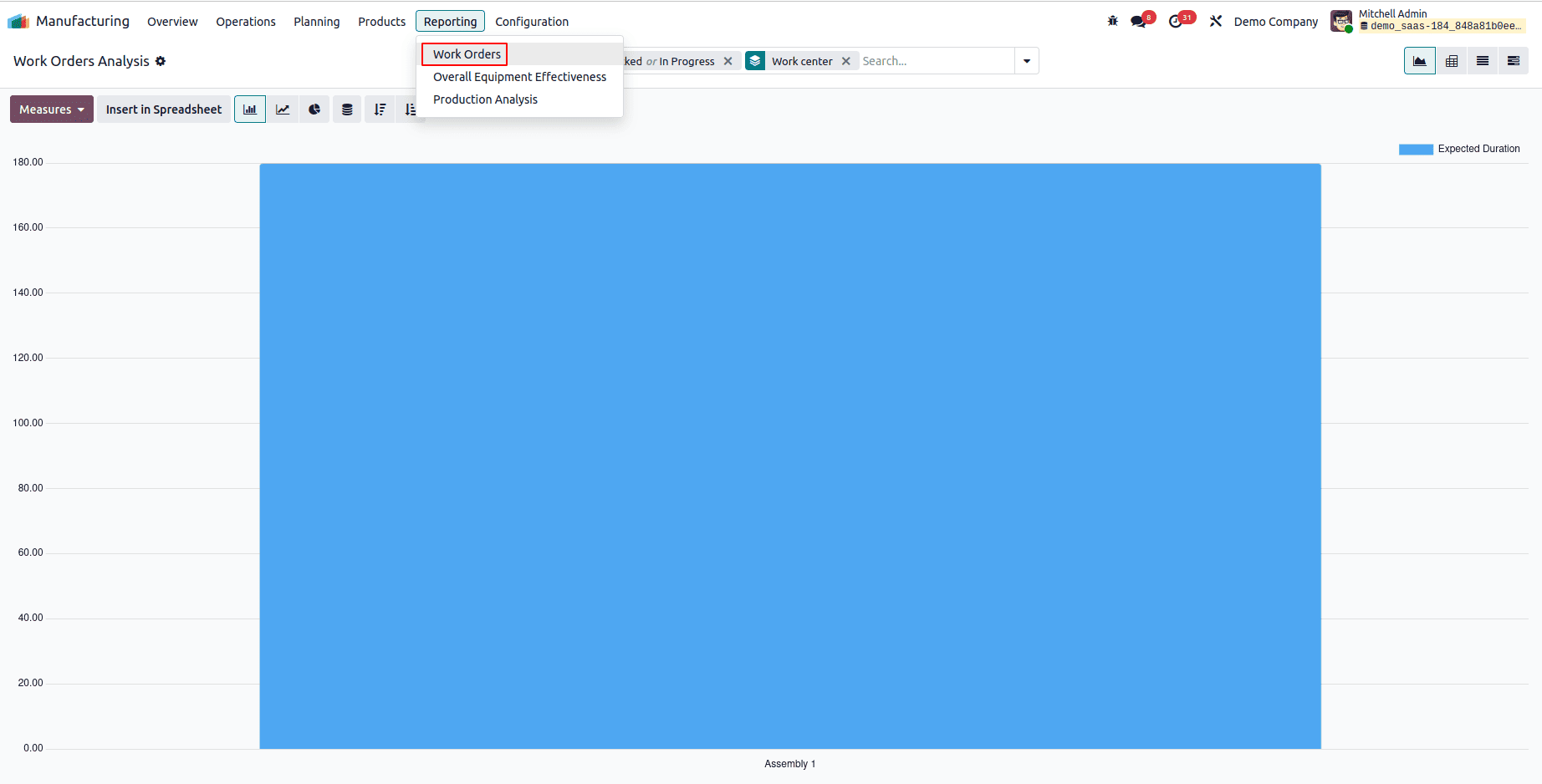

Work orders generated within the module can be effectively analyzed through the "Work Orders" reporting feature. This tool provides multiple view options, including Graph, Pivot, List, and Gantt formats, allowing for comprehensive insights. An example of the graphical view is illustrated below.

The graph view can be customized to display data as a line chart, pie chart, or bar chart, with sorting options available in both ascending and descending order. Odoo provides built-in filters to help generate reports based on work order stages such as Ready, Waiting, Pending, In Progress, Done, Late, and Start Date. Additionally, the "Group By" feature enables you to organize reports by Work Center or Product. Both the Filters and Group By options are highly customizable, allowing you to create tailored reports that meet your specific analysis needs.

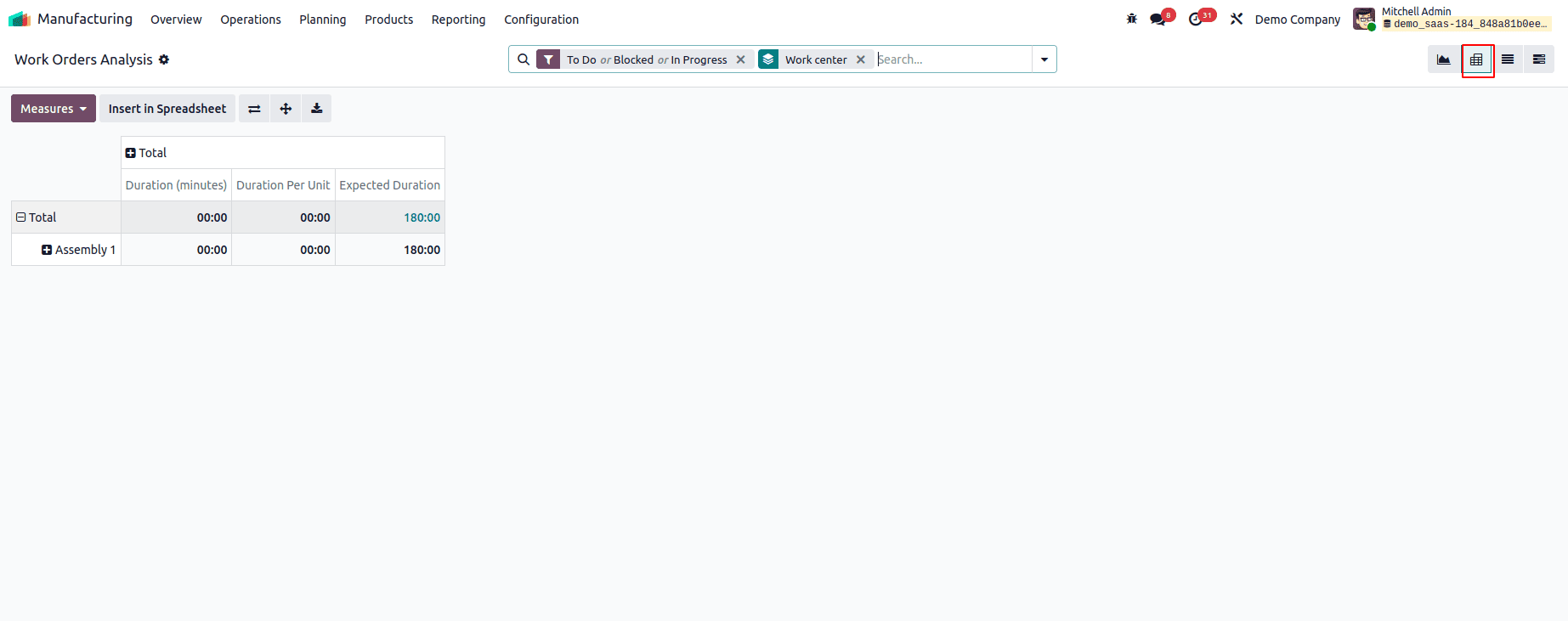

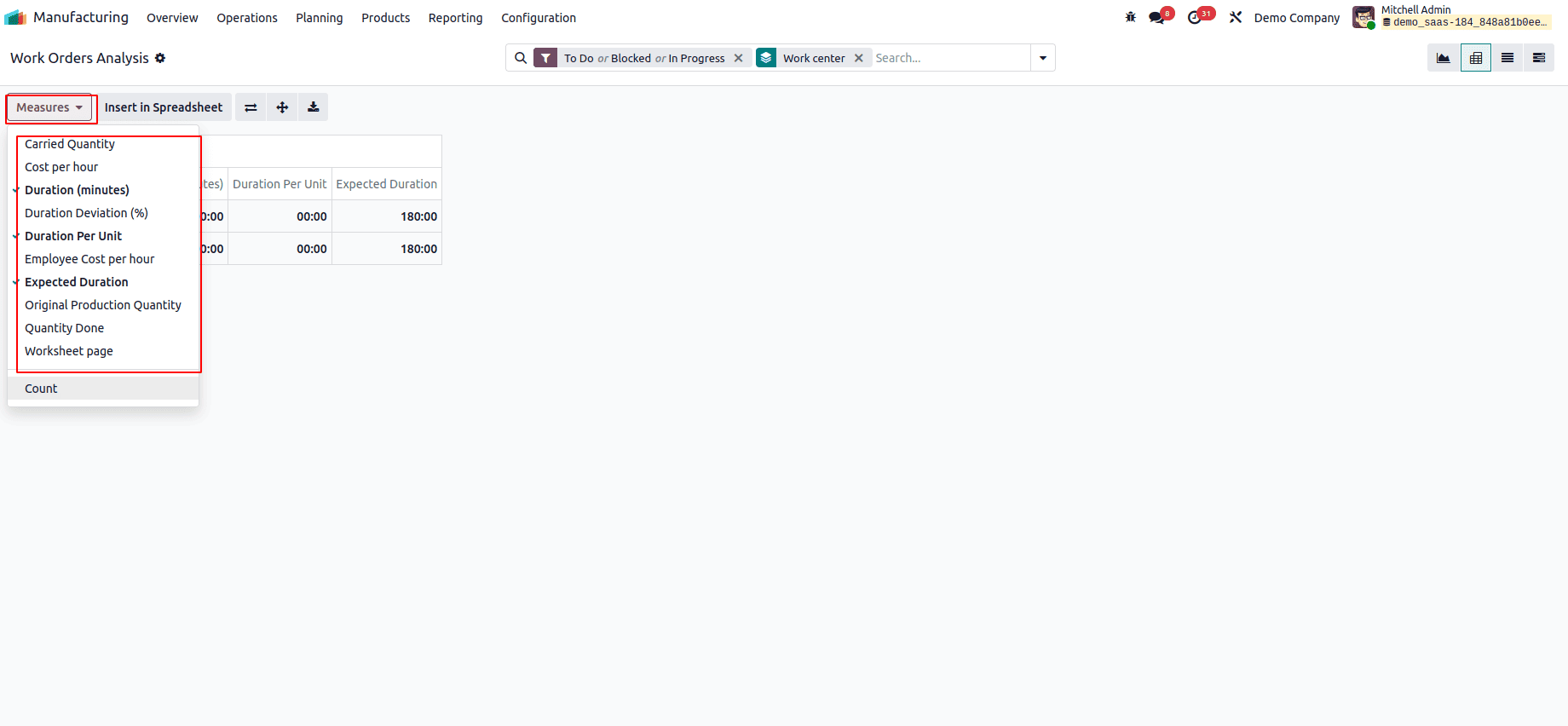

The Pivot Table view can be expanded by selecting various measures such as Carried Quantity, Cost per Hour, Duration, Duration Deviation, Duration per Unit, Expected Duration, Quantity, and Worksheet Page. For more in-depth analysis, the report can be easily added to a spreadsheet using the Insert in Spreadsheet option.

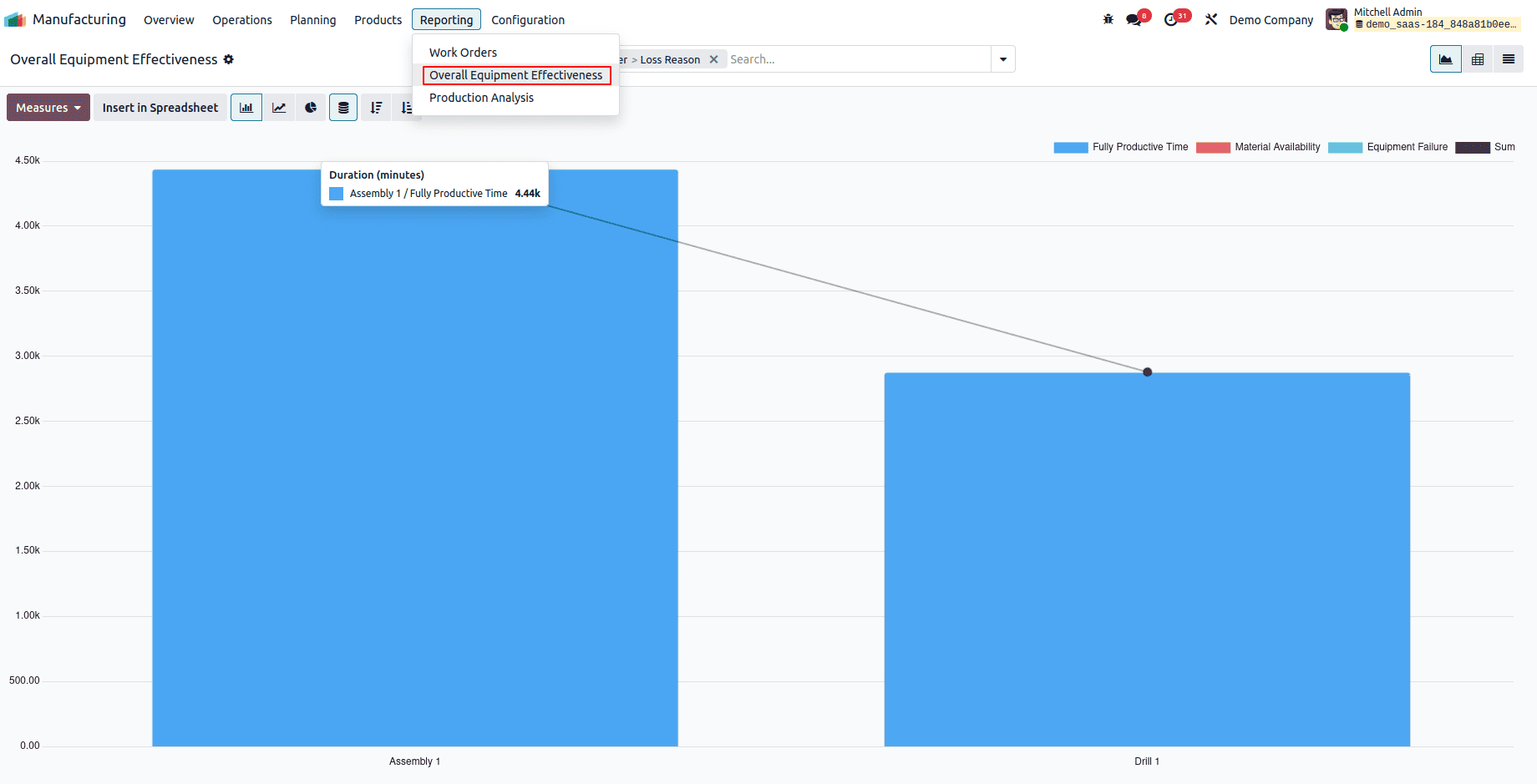

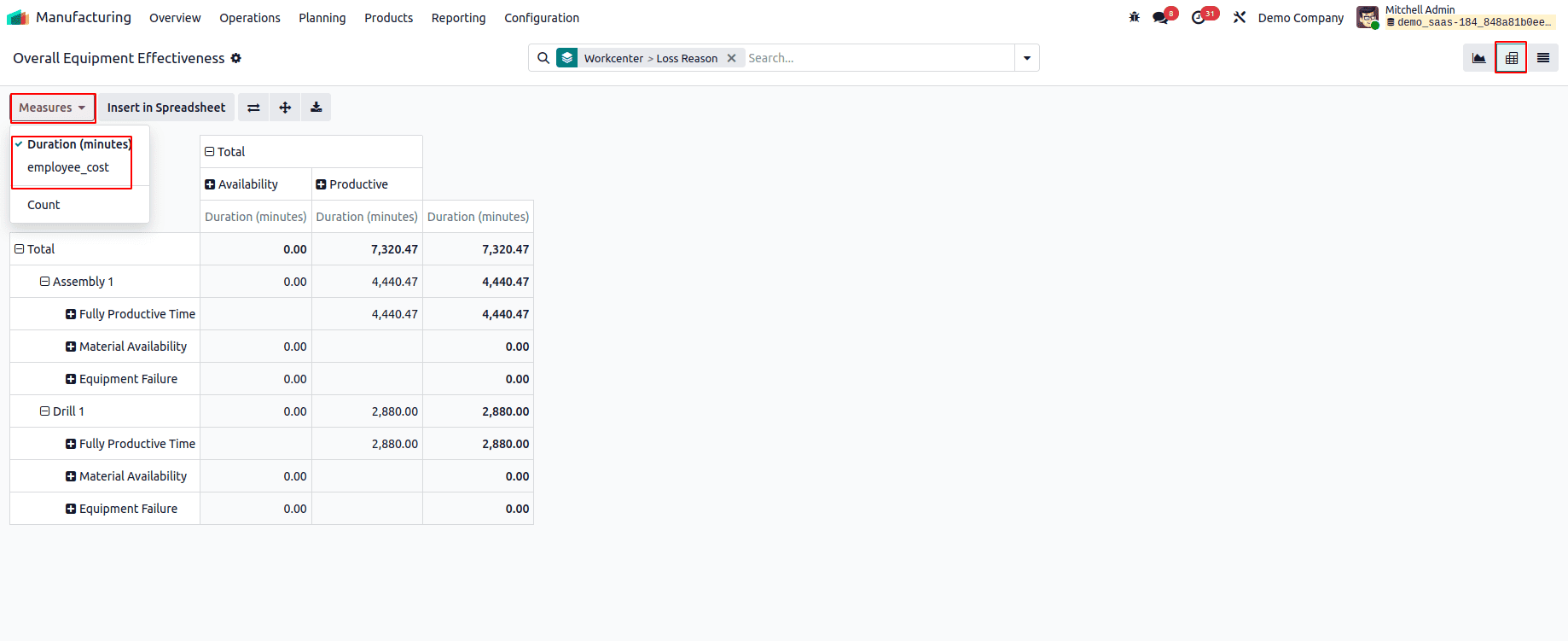

Overall Equipment Effectiveness

You can assess the overall equipment effectiveness (OEE) of your company's work centers through the dedicated OEE reporting feature. This platform allows you to generate reports filtered by user, work center, or reason for loss, providing valuable insights into operational efficiency.

To enhance the accuracy of the report, you can apply filters such as Availability Losses, Performance Losses, Quality Losses, Fully Productive, and Date. These filters help refine the data for a more detailed and meaningful analysis.

The report measures can be configured to display data based on Duration, Employee Cost, and Count, allowing for a more targeted and insightful analysis.

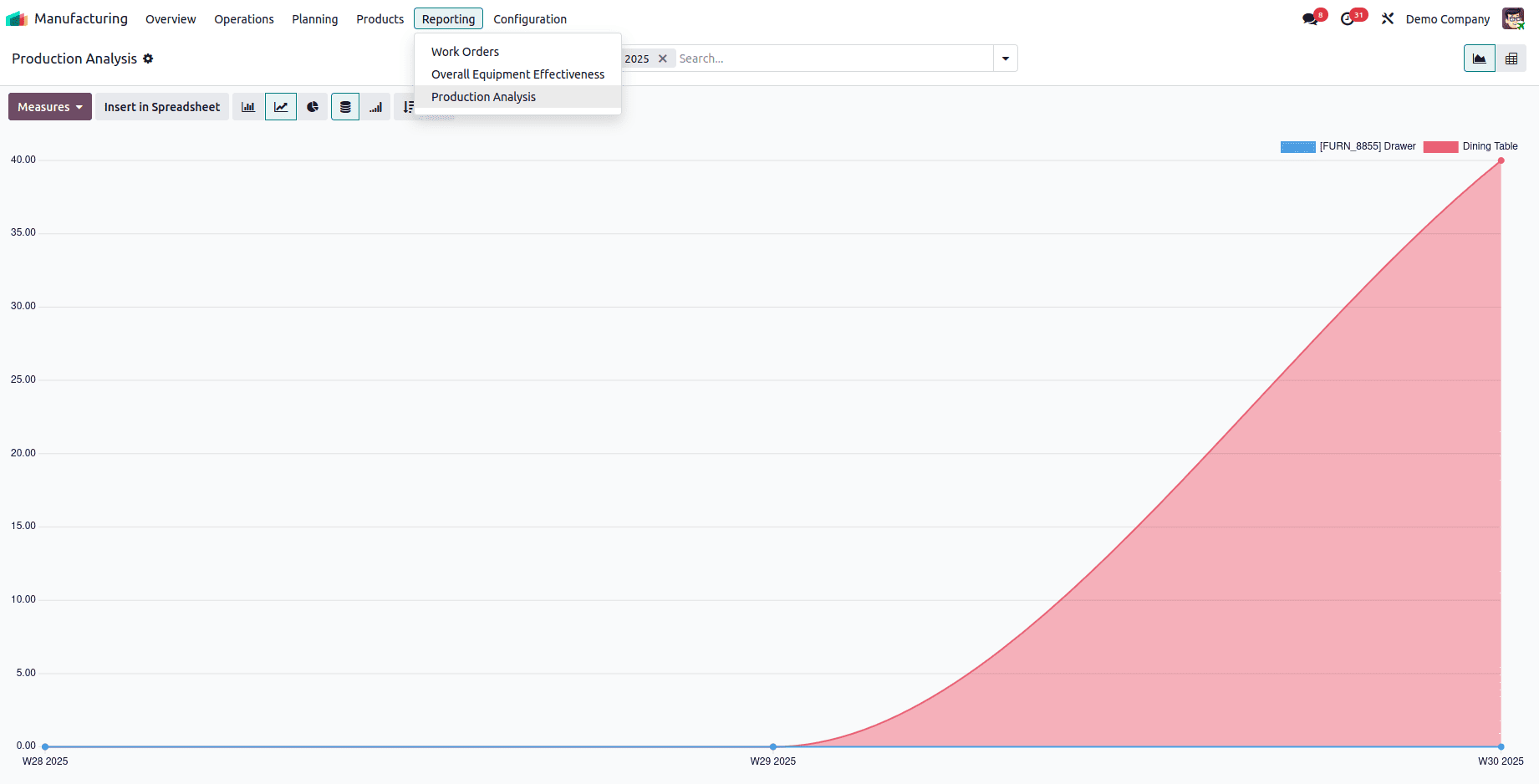

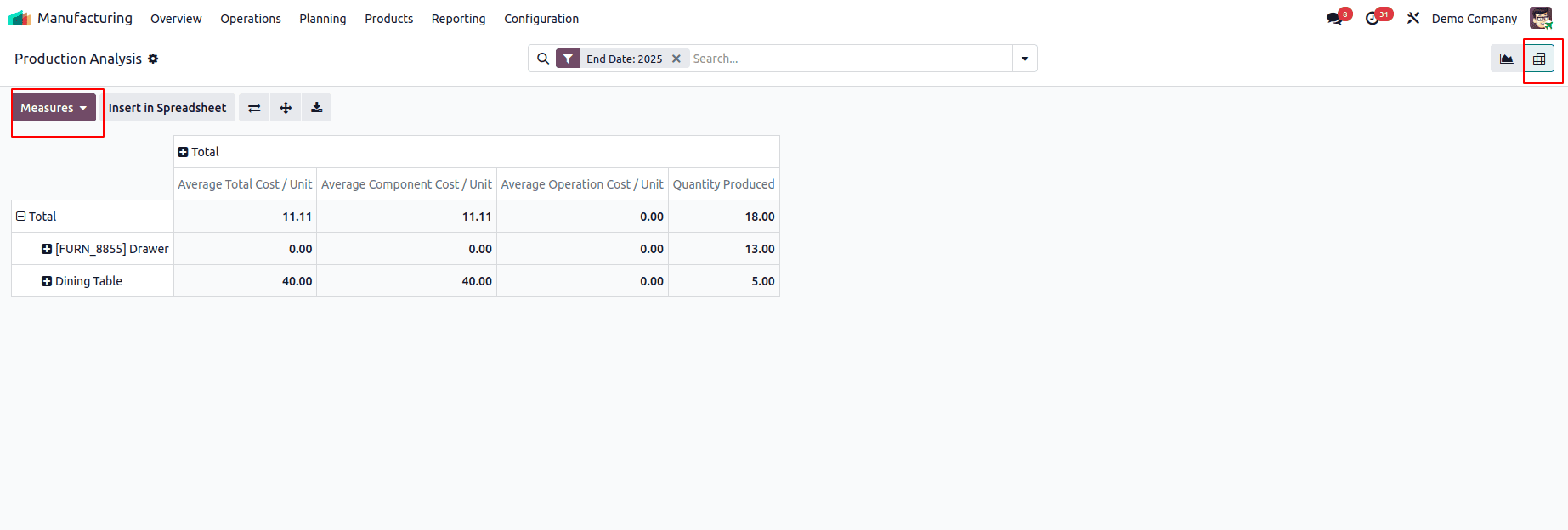

Production Analysis

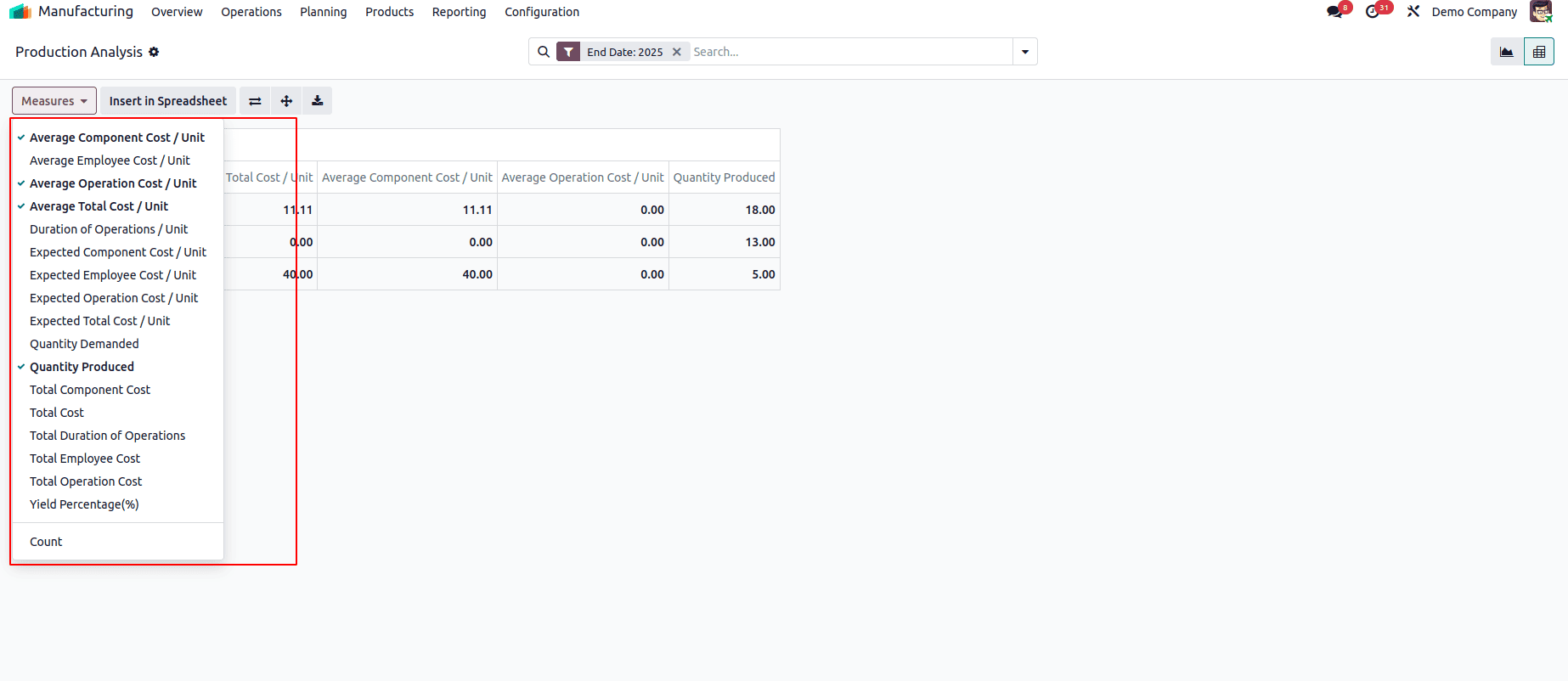

To analyze production performance over different time periods—daily, weekly, monthly, or yearly—you can use the Production Analysis option available under the Reporting menu. This feature generates detailed reports based on criteria such as product and end date, offering valuable insights into production trends.

By applying the End Date as a filter, you can generate production reports that reflect the completion timeline for each product, helping you track and evaluate production outcomes more effectively.

In this report, you can include various measures to gain deeper insights, such as Average Component Cost per Unit, Average Operation Cost per Unit, Average Subcontracting Cost per Unit, and Average Total Cost per Unit. Additional metrics like By-Products Total Cost, Duration of Operations per Unit, Quantity Produced, Total Component Cost, Total Cost, Total Duration of Operations, Total Operation Cost, Total Subcontracting Cost, and Count can also be added to provide a comprehensive analysis of production performance and expenses.

Overall, Odoo’s manufacturing reporting features provide a comprehensive overview of production activities. From tracking work orders and analyzing equipment efficiency to evaluating production costs and timelines, these tools help streamline decision-making through flexible filters, detailed measures, and various visualization options.

To read more about How to Manage Manufacturing Orders with Odoo 18, refer to our blog How to Manage Manufacturing Orders with Odoo 18