In any manufacturing process, maintaining product quality is crucial to ensuring customer satisfaction, reducing waste, and meeting compliance standards. Odoo 18 offers a robust and flexible Quality Management system that seamlessly integrates with the Manufacturing module. With features like quality control points, checks during different production stages, and automated workflows, Odoo helps manufacturers enforce strict quality standards without slowing down production. In this blog, we’ll explore how quality checks can be set up and managed in Odoo 18's Manufacturing module, enabling businesses to deliver consistent, high-quality products efficiently.

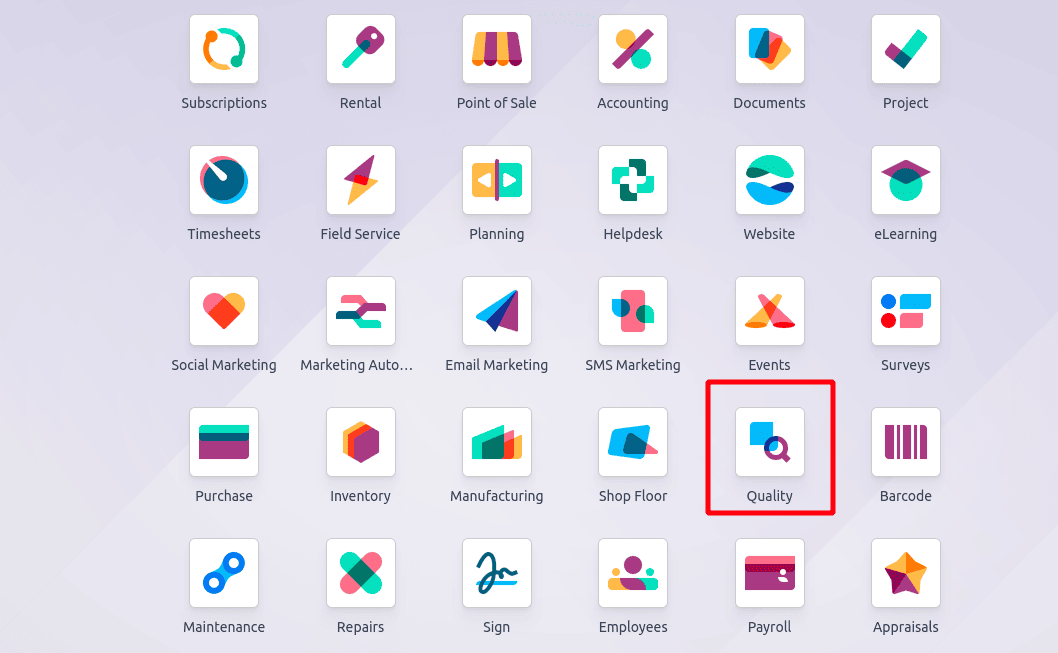

To get started, simply install the Quality module from the Odoo Apps. Once installed, open the module to begin setting up your quality control processes.

Quality Control Points

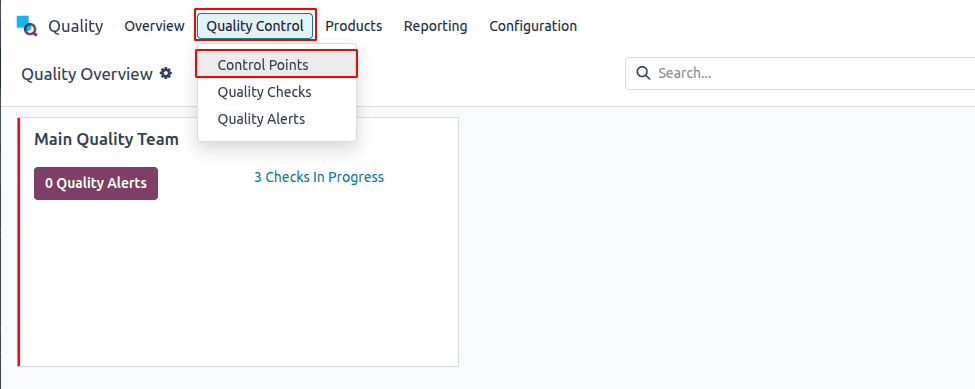

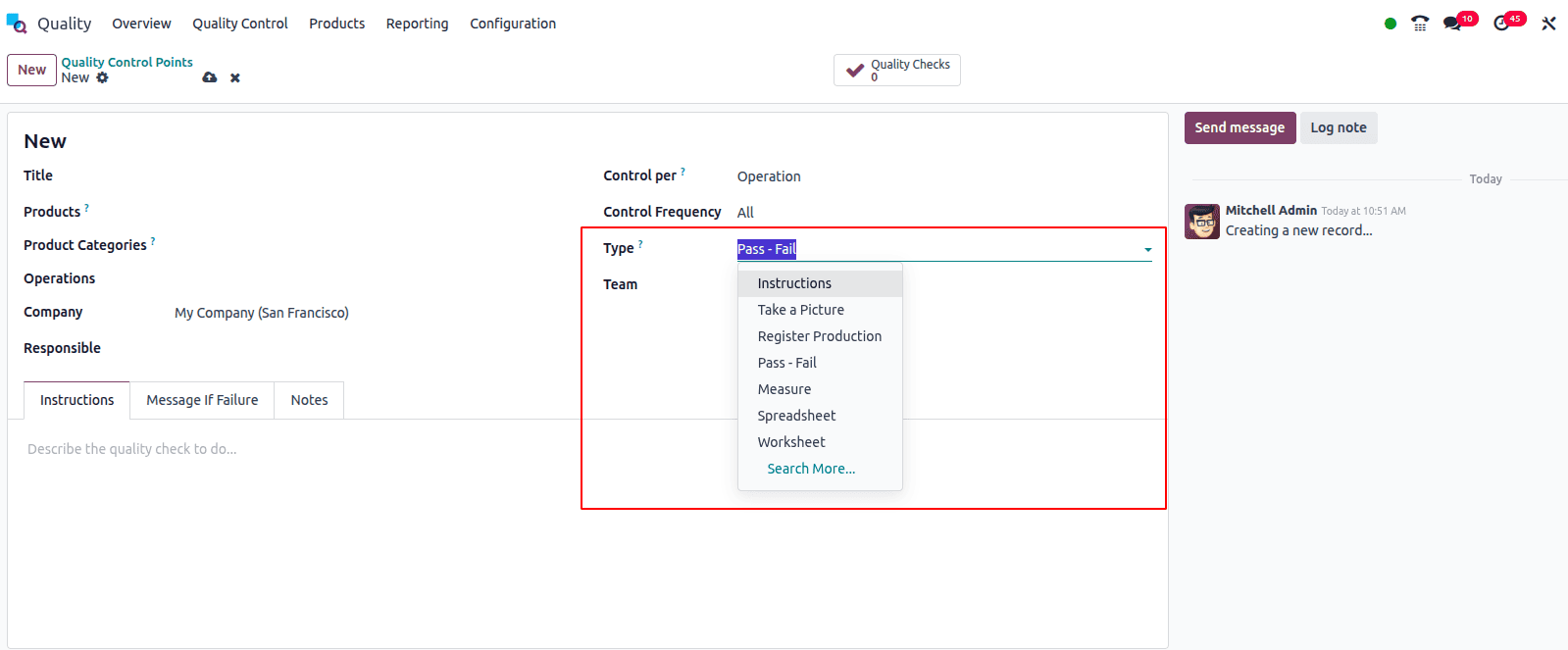

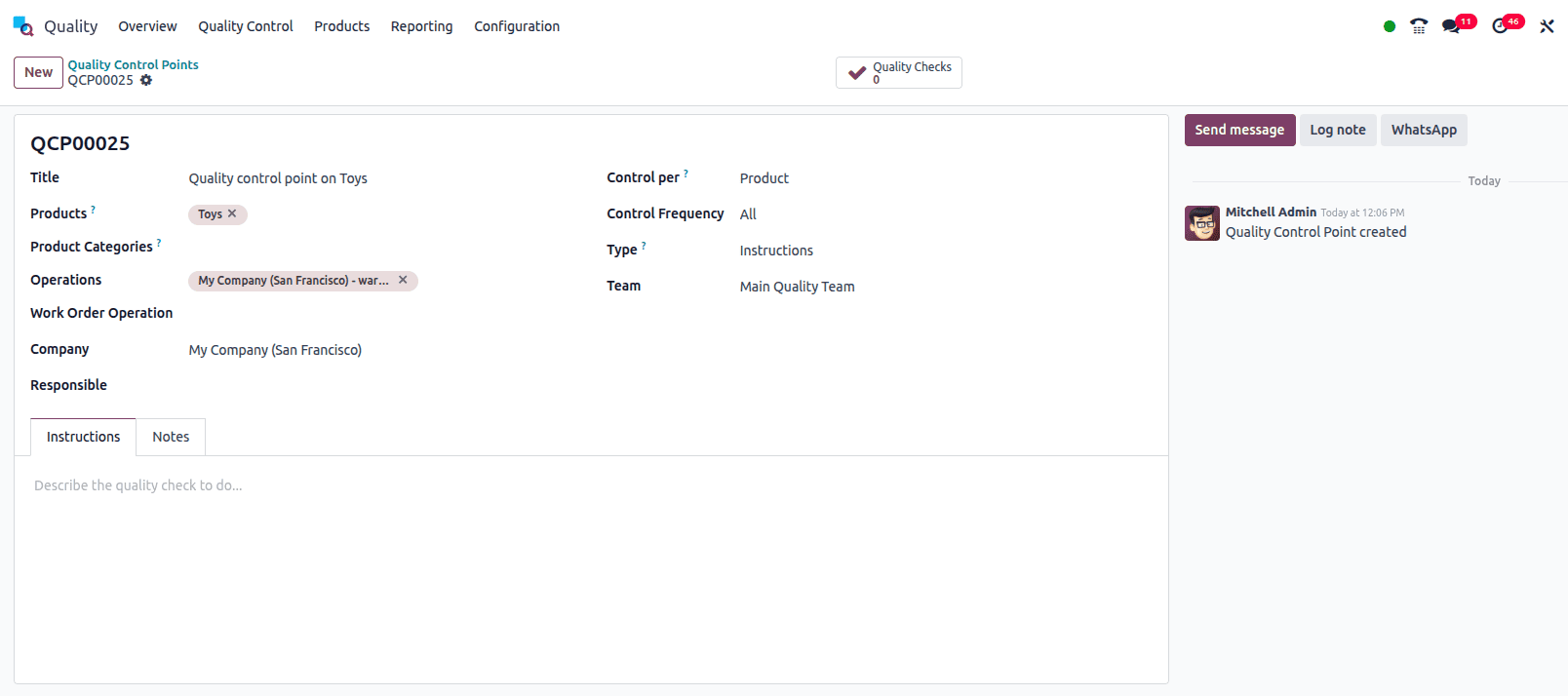

Quality control points define the specific stages where product inspections are required. Setting up evaluation methods for product quality is easy. You can access these configurations by going to the Control Points option within the Quality Control tab.

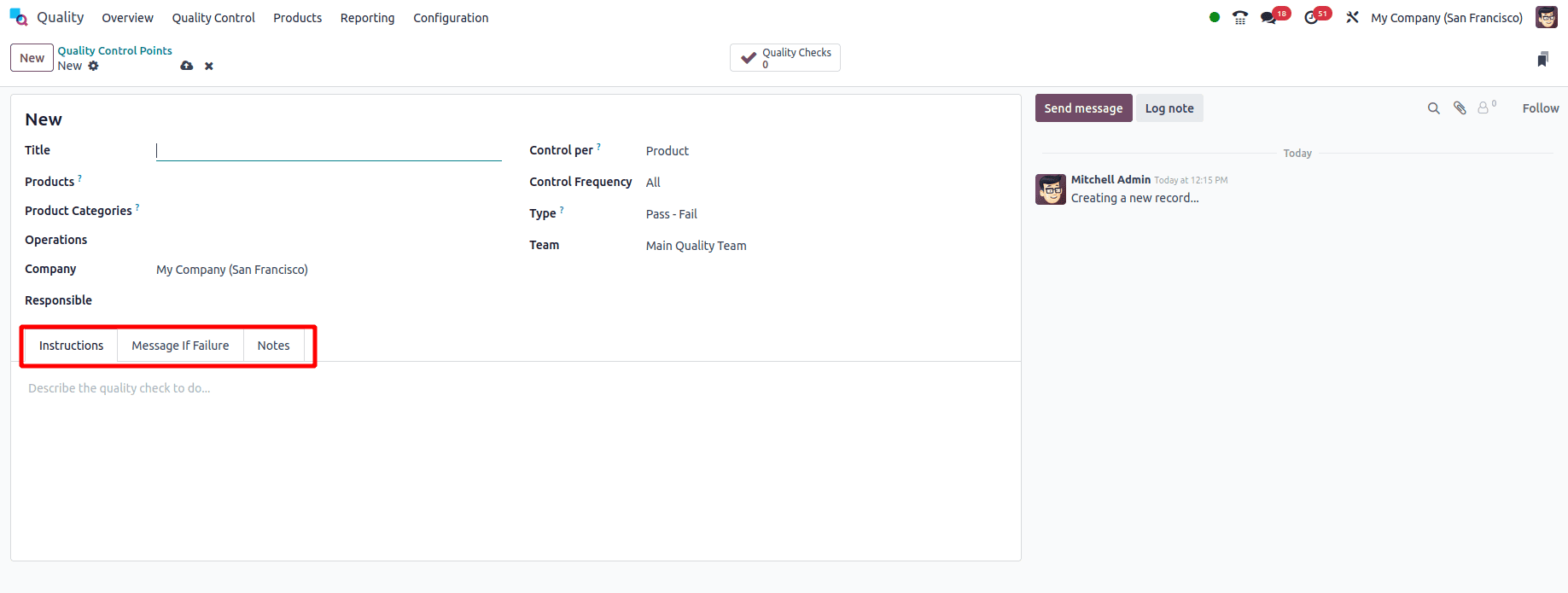

Quality control points can be set up from this menu. Start by giving a suitable title to the control point. You can configure checks for individual products, entire product categories, or specific operations. Additionally, you can define the company involved, assign the relevant quality team, and select the responsible person.

Guidelines for performing the quality check can be entered under the Instructions tab. If the check does not pass, an appropriate message can be shown, which is set under the Message If Failure tab. Any extra details or comments can be noted in the Notes tab.

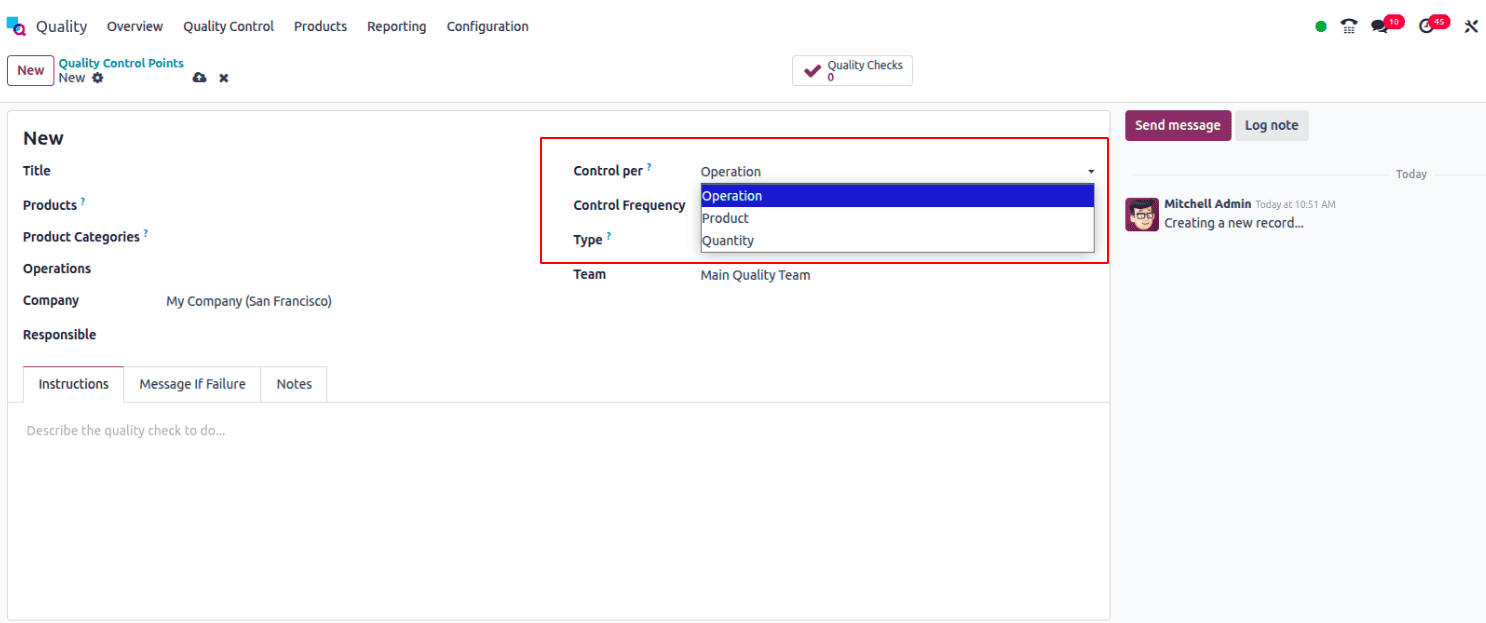

Quality checks can be configured based on three criteria: product, operation, or quantity. When an operation is selected, the check is executed during that specific operation. Selecting a product applies the check directly to that item. If quantity is chosen, a quality check is initiated for every newly recorded quantity, supporting partial inspections as well. We’ll go through each option individually in the following sections.

The type of product determines the kind of quality checks that can be applied.

Control Per Operation

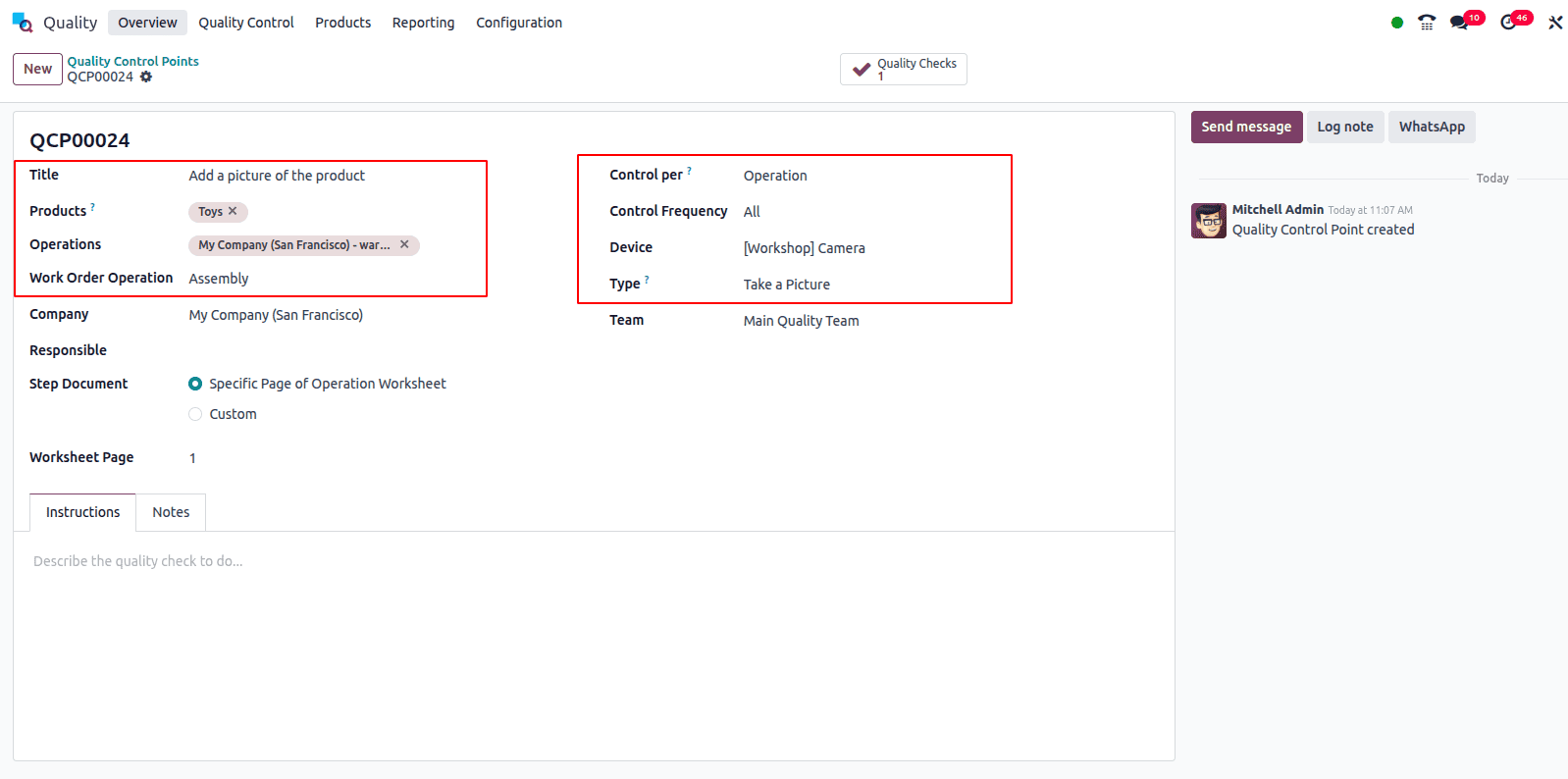

When quality control is configured per operation, a check is triggered each time the specified operation takes place, regardless of the product.

In this example, a control point is set for the Manufacture operation, with the quality check type defined as Take a Picture. This means that whenever manufacturing is carried out, the user must capture and upload a photo to verify the condition of the items. Since no specific product is selected, the check applies to all products processed under the Manufacture operation across the company.

You can also specify which device should be used to take the picture by selecting it in the Device field.

Let’s see how this works with the Manufacture operation. We'll create a control point linked to the manufacturing process to trigger the quality check accordingly.

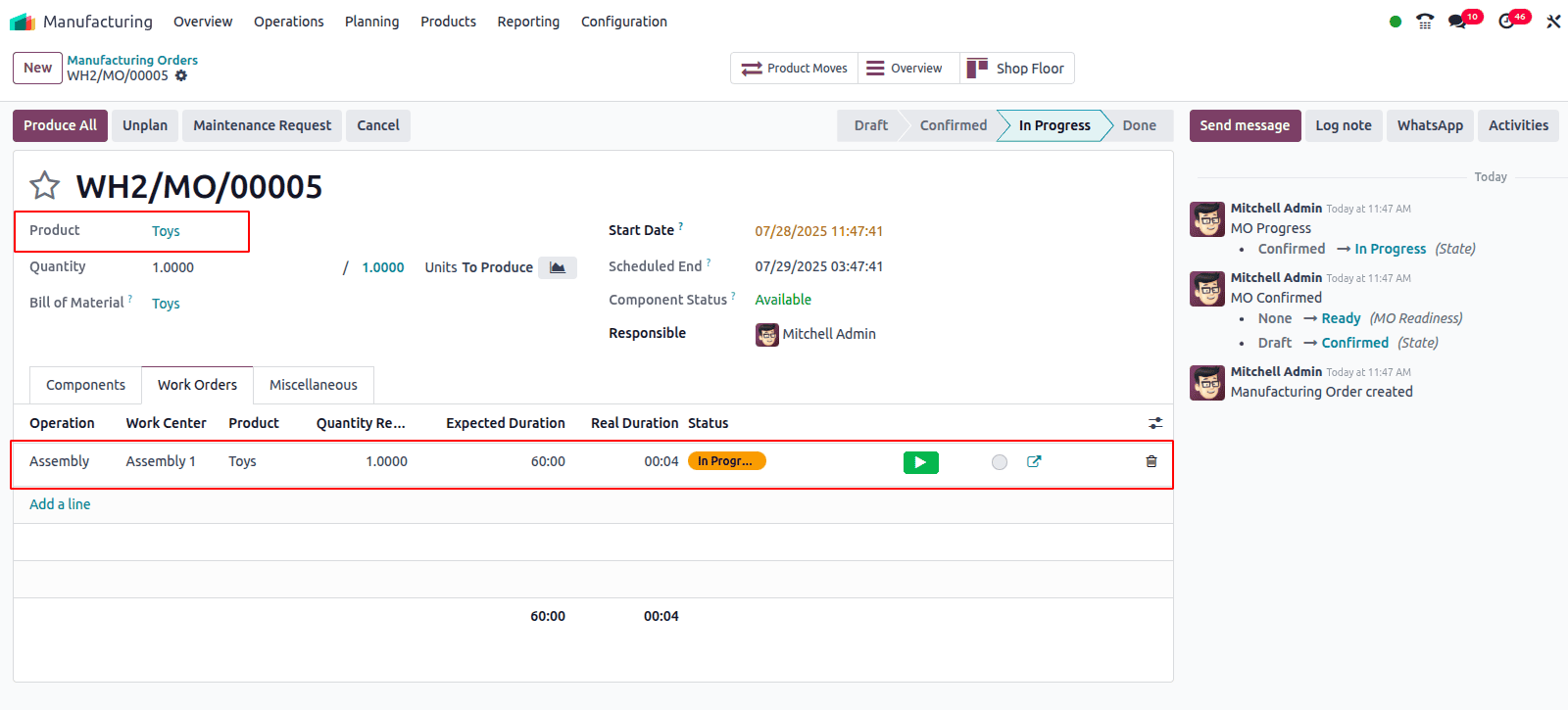

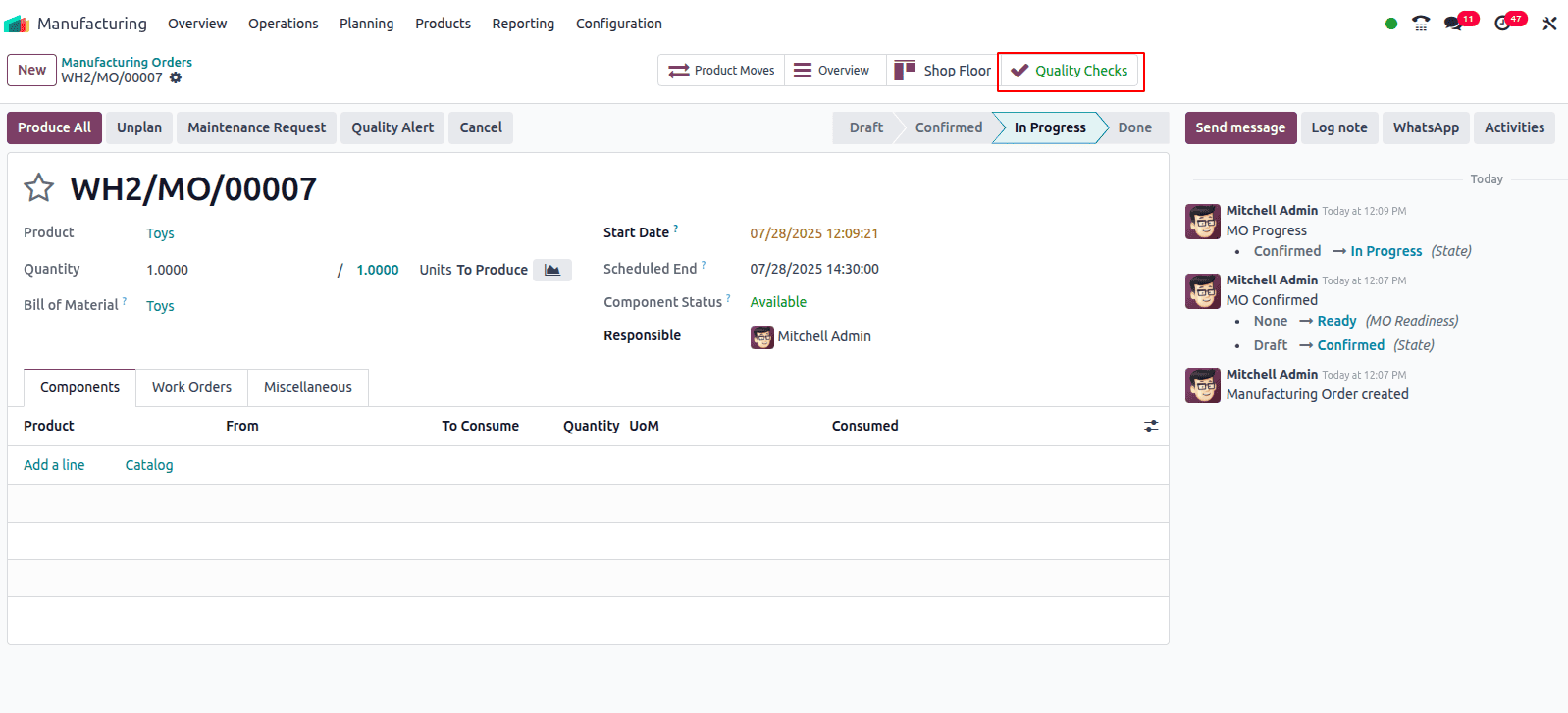

Navigate to the Manufacturing module and create a manufacturing order for the relevant product.

To validate the quality check, you can either use the Shop Floor smart button for quick access or go to the Quality Checks section found under the Quality Control tab in the Quality module.

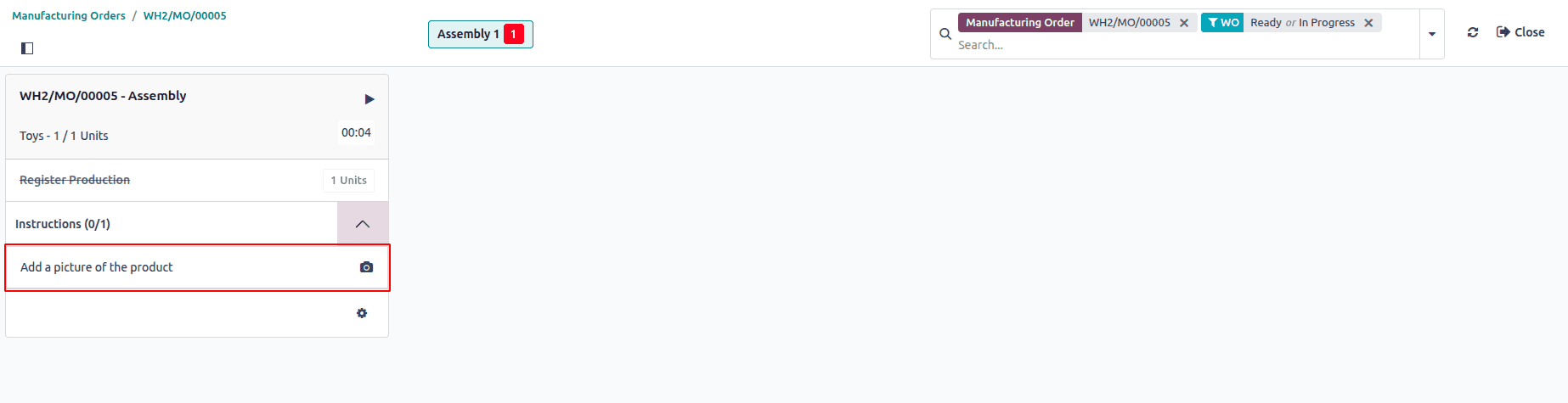

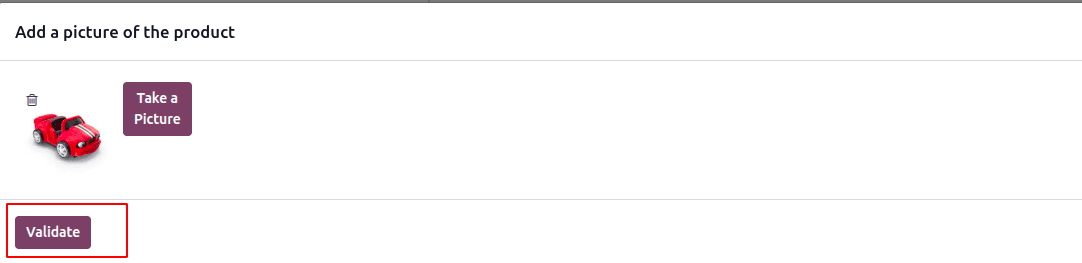

A pop-up window will appear to perform the quality check. Since the check type is Add a Picture, the user is prompted to upload an image of the product. Simply attach the required photo in the provided section, and click the Validate button to finalize the quality check process.

Control Per Product

In this configuration, the quality check is assigned to a particular product within a specific operation. The operation will only proceed once the quality check for that product is successfully completed.

For instance, a quality control point has been set up for the product Toys, with the title "Quality Control Point on Toys". The product is selected in the control point, and the operation is defined as Manufacturing. This ensures that once the Toys are manufactured, the system will prompt a quality check before completing the process.

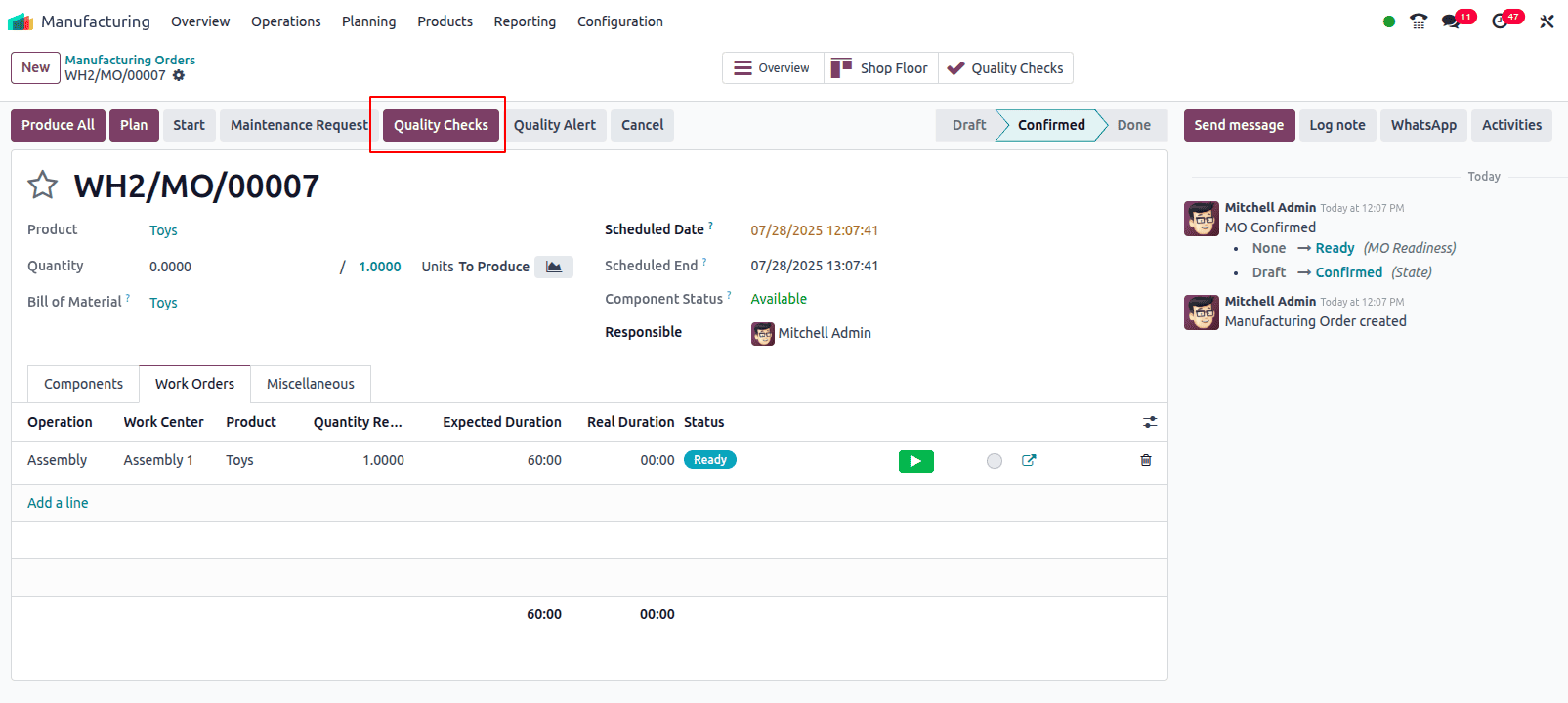

A manufacturing order is created, and once the production is completed, the product's quality can be verified by clicking the Quality Check button.

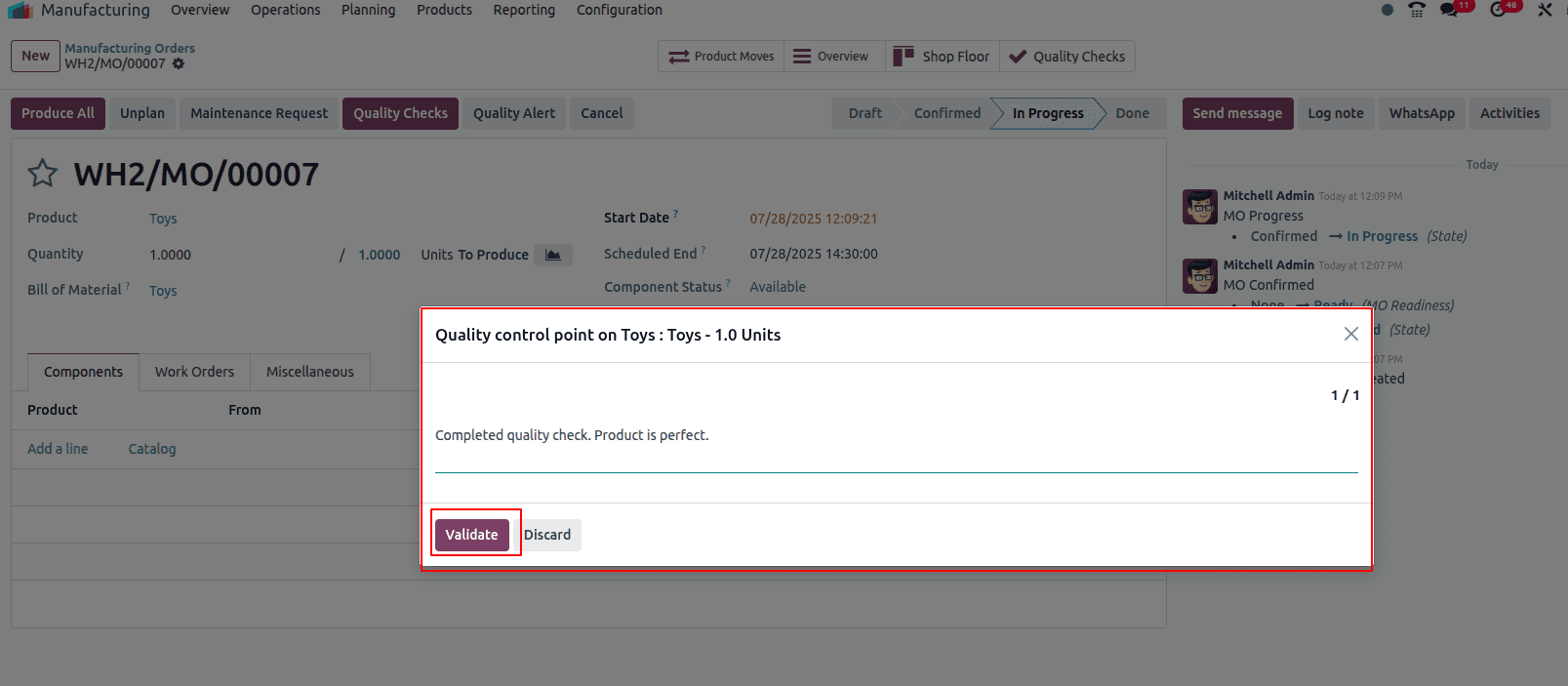

A pop-up window will appear displaying the title specified in the Quality Control Point. The user can enter any additional remarks related to the quality check before clicking Validate to complete the process.

Once the quality check is successfully completed, the Quality Checks smart tab turns green, indicating completion.

Control Per Quantity

This configuration triggers quality checks based on the quantity of products. It can be used when every unit needs to be inspected or when only a sample percentage of the total quantity is sufficient to assess the overall quality. This approach is suitable for both full and partial inspections.

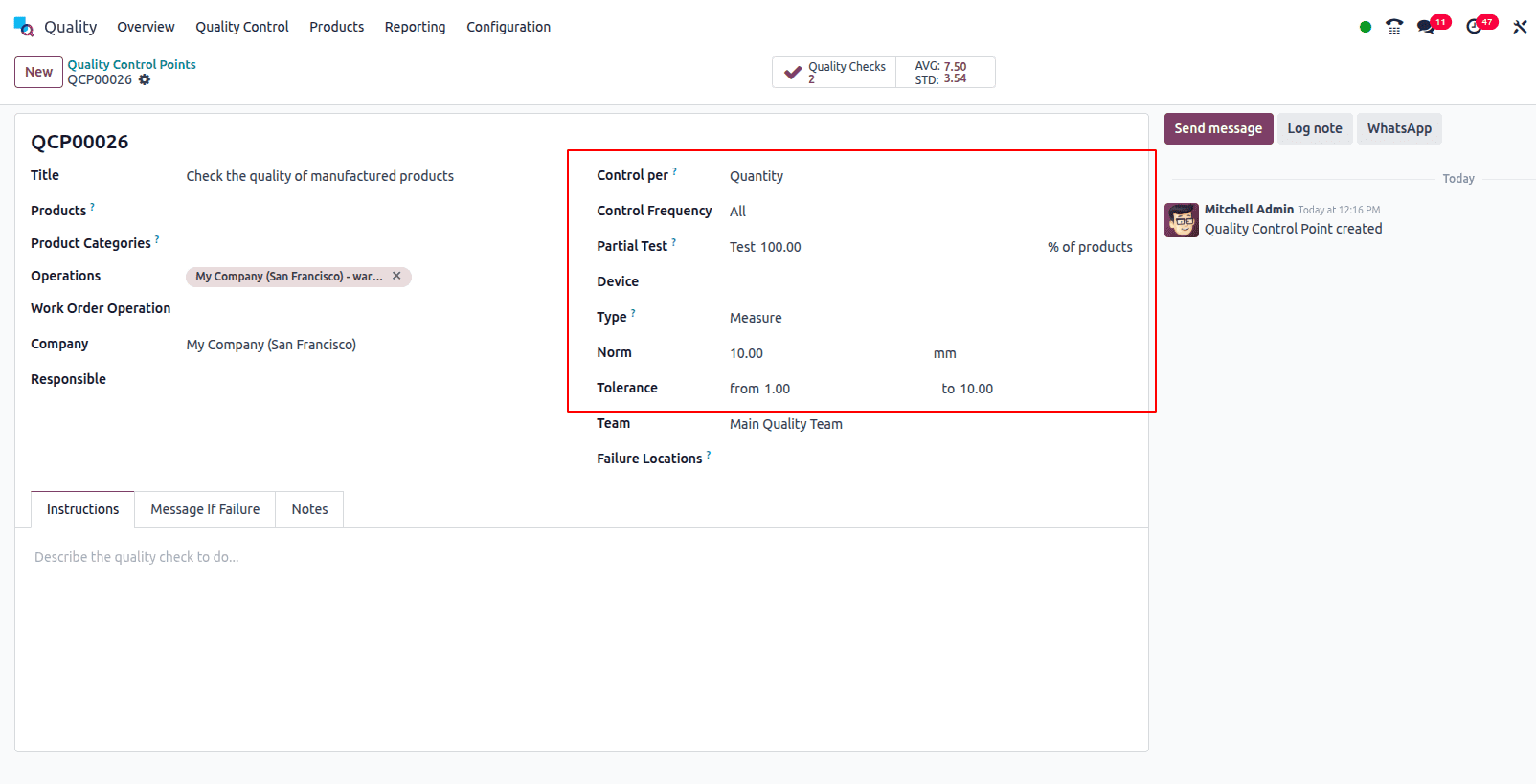

In this example, a control point is configured for the Manufacture operation, with Control Per set to Quantity. This means that each unit produced must go through a quality check.

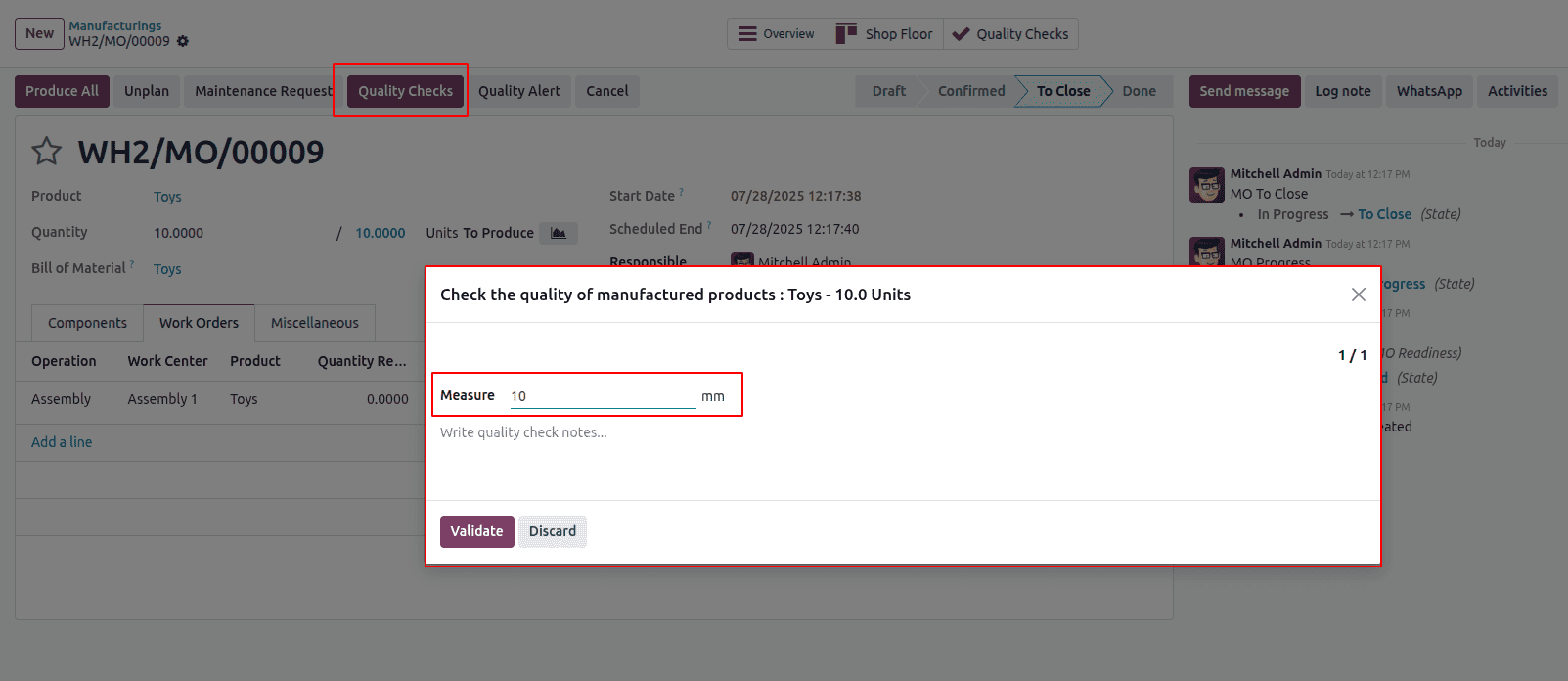

In this case, the quantity is 10. Enter a measurement value between 1 and 10, then proceed to validate the quality check.

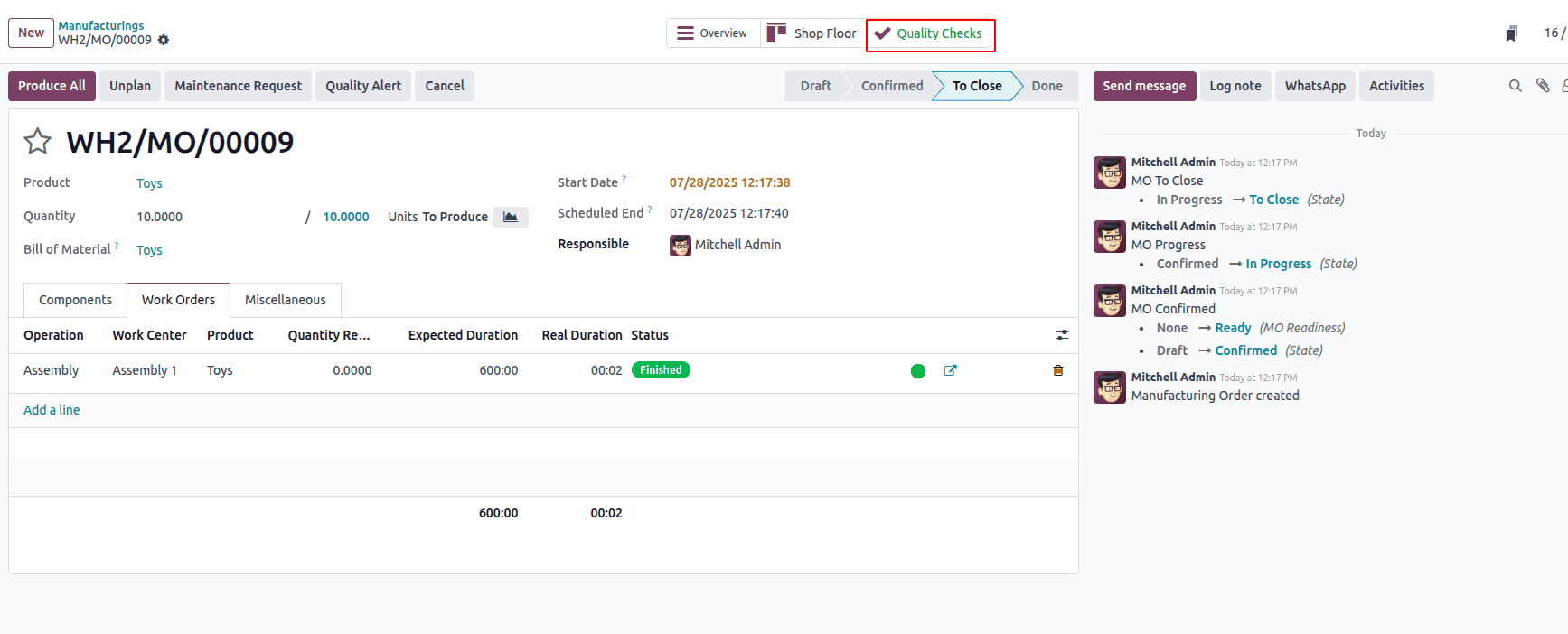

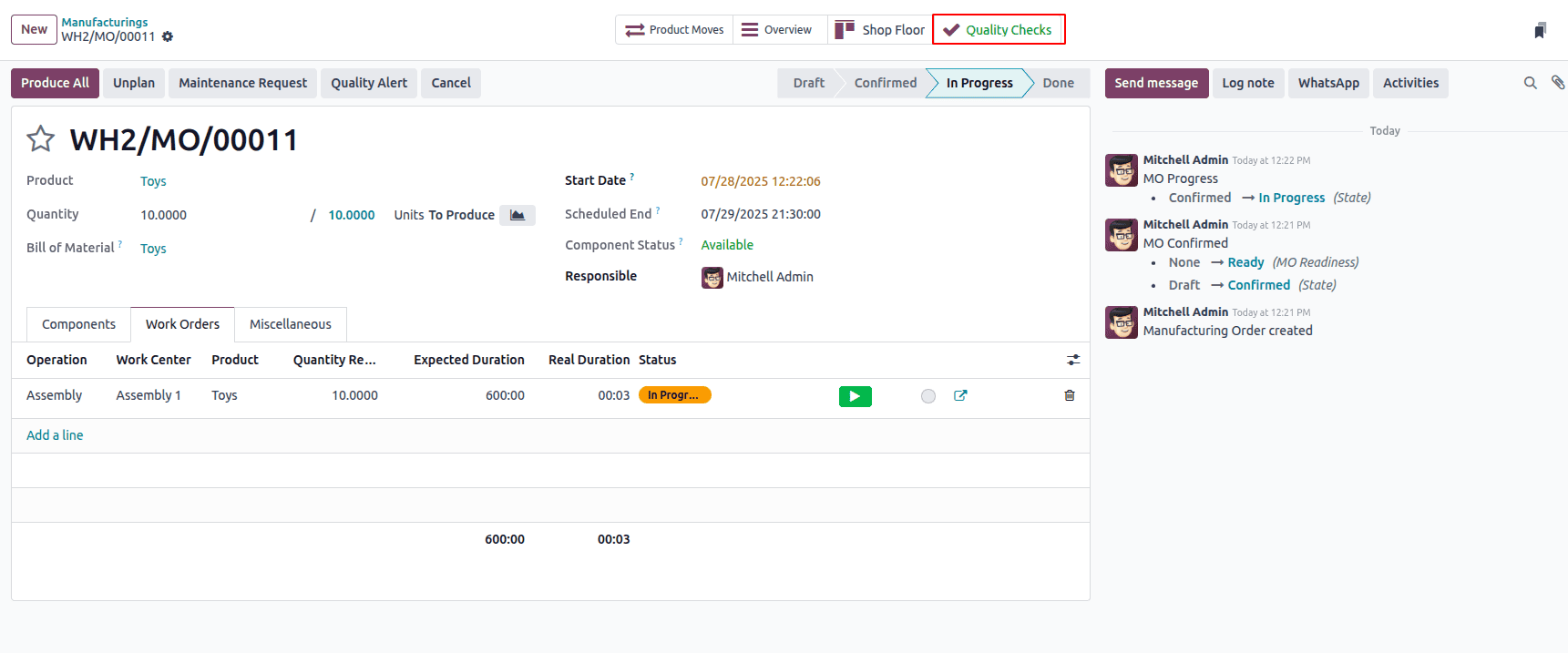

Once the quality check is validated, the Quality Checks smart tab turns green, indicating successful completion.

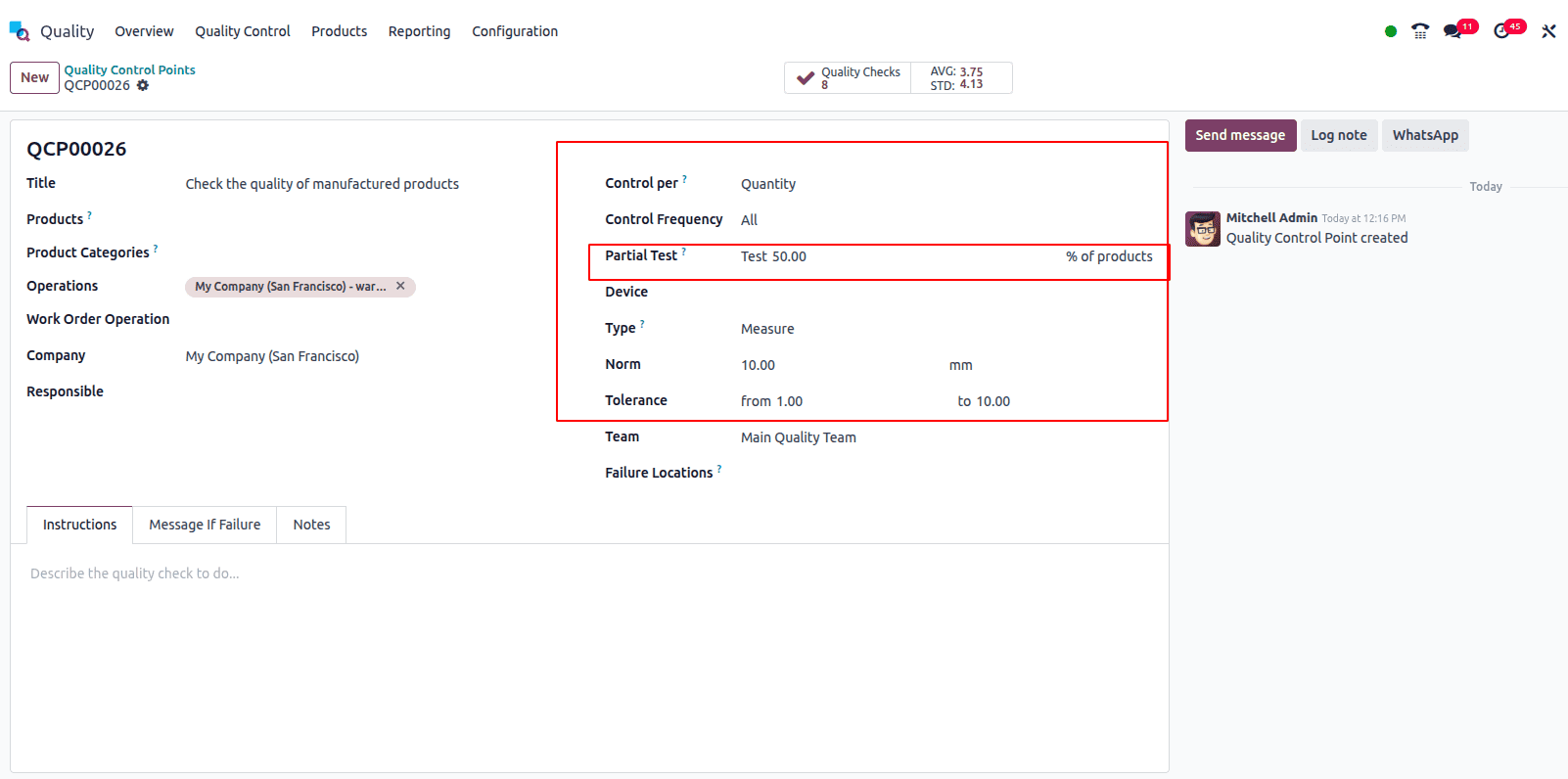

In certain cases, checking the full quantity isn't required to ensure the quality of Manufactured items. Instead, a specific percentage can be defined using the Partial Test option. In this example, the existing quality control point has been modified to reflect this setting.

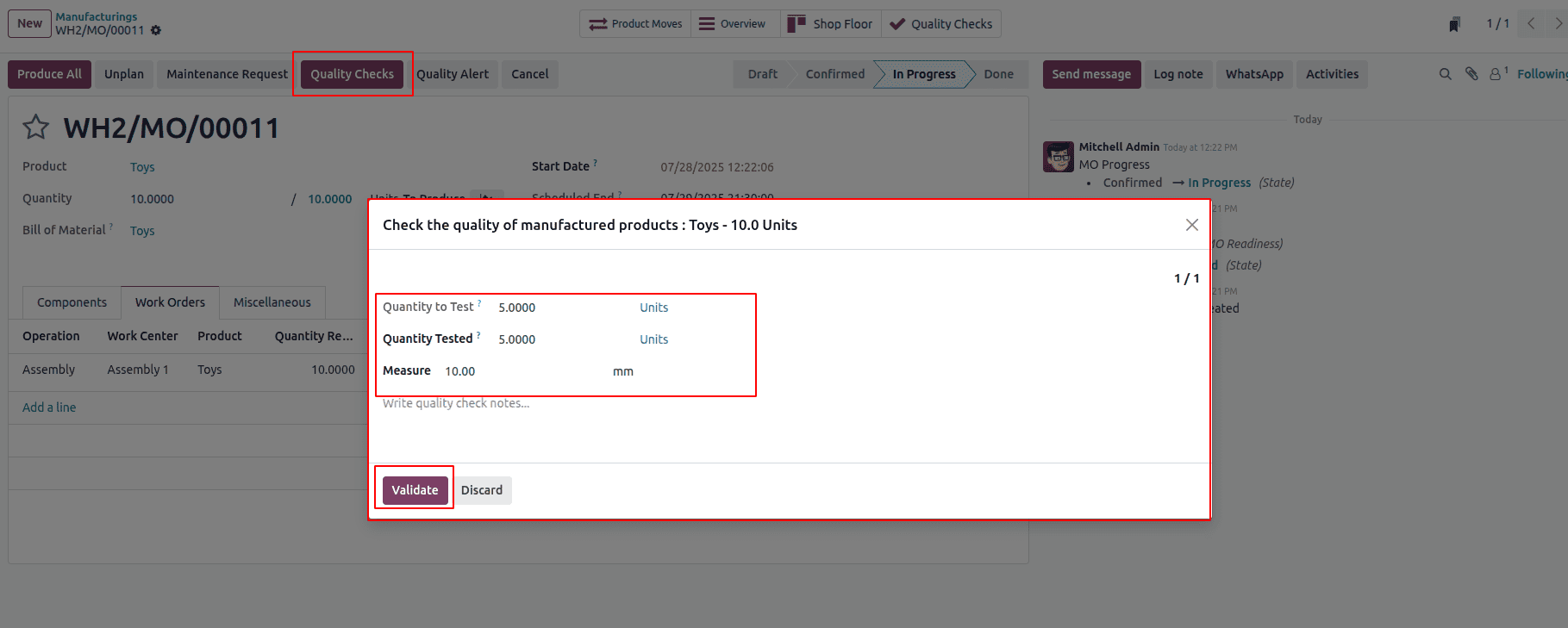

In this case, the total quantity is 10, and the quantity selected for testing is 5, representing 50% of the total. The user is required to inspect only this portion to complete the quality check.

Next, enter the quantity tested, in this case, only a partial amount is provided. After entering the value, click Validate to complete the quality check.

Even though only 5 out of 10 units were examined, the full quantity is marked as approved. The user can then move forward and complete the process.

This is how the quality checks work in the Odoo 18 Manufacturing module.

With the help of the Quality module in Odoo 18, businesses can efficiently define and manage quality control points while performing various types of quality checks to identify and address issues promptly. This not only helps minimize product defects but also reduces the chances of customer complaints, leading to higher customer satisfaction.

Maintaining consistent product quality increases reliability, extends product lifespan, and strengthens the overall reputation and performance of the business. Additionally, integrating quality control into daily operations supports better decision-making and continuous improvement.

To read more about What are the Types of Quality Checks Available in Odoo 17, refer to our blog What are the Types of Quality Checks Available in Odoo 17