Throughout a product's lifecycle, engineering modifications, revisions, and product designs can be managed with the aid of Odoo 18's PLM (Product Lifecycle Management) module. To ensure that design revisions are appropriately reflected in production, it interfaces with manufacturing to expedite the implementation of Engineering Change Orders (ECOs). The PLM module enhances version control, traceability, and overall product quality by facilitating communication between engineering and production teams.

An Engineering Change Order (ECO) is a formal procedure in Odoo 18 that is used to handle changes to routings, Bills of Materials (BoMs), or product designs. Changes can be proposed, reviewed, approved, and implemented in a controlled and verifiable manner by engineering and manufacturing teams. By ensuring that all parties involved are informed and on the same page before changes are implemented, the ECO process lowers the likelihood of mistakes and production interruptions. BoMs can manage multiple revisions and track the lifespan of each modification using Odoo's version control feature. In dynamic industrial environments, this feature aids in maintaining product quality, compliance, and efficiency.

Adding Engineering Change Orders (ECOs) to products and Bills of Materials (BoMs) in Odoo 18 has the following main advantages:

- Enhanced Traceability: Provides complete visibility and auditability by tracking all modifications made to products or BoMs.

- Version Control: Preserves several iterations of the BoMs, making it simple to roll back or consult earlier designs.

- Controlled Change Process: This minimises errors by making sure changes are examined and approved before implementation.

- Team Collaboration: Improves coordination amongst quality, manufacturing, and engineering departments.

- Decreased Production Errors: Maintains the shop floor in line with the most recent product guidelines and specifications.

- Quicker Update Implementation: Updates are implemented more quickly, which expedites the application of required design or component modifications.

- Compliance and Quality Assurance: By using structured change management, this approach helps maintain product quality and satisfy regulatory standards.

- Impact Analysis in Real Time: Before implementing changes, real-time impact analysis enables evaluation of their effects on inventory, cost, and production.

At every level of an Engineering Change Order (ECO) in Odoo 18 PLM, authorisation from a designated individual guarantees quality control, accountability, and regulatory compliance. Before implementing changes, it helps ensure that they are technically sound, economical, and in line with organisational objectives. Additionally, this phased clearance process reduces errors, prevents unauthorised changes, and makes traceability easier for audits or subsequent reviews.

This blog post describes how users may set up several approval types in Odoo 18 PLM at every step of the Engineering Change Order (ECO) process. It encompasses process management, designating authorised workers, and establishing approval rules. Users may guarantee effective, traceable, and controlled engineering change management by being aware of these setups.

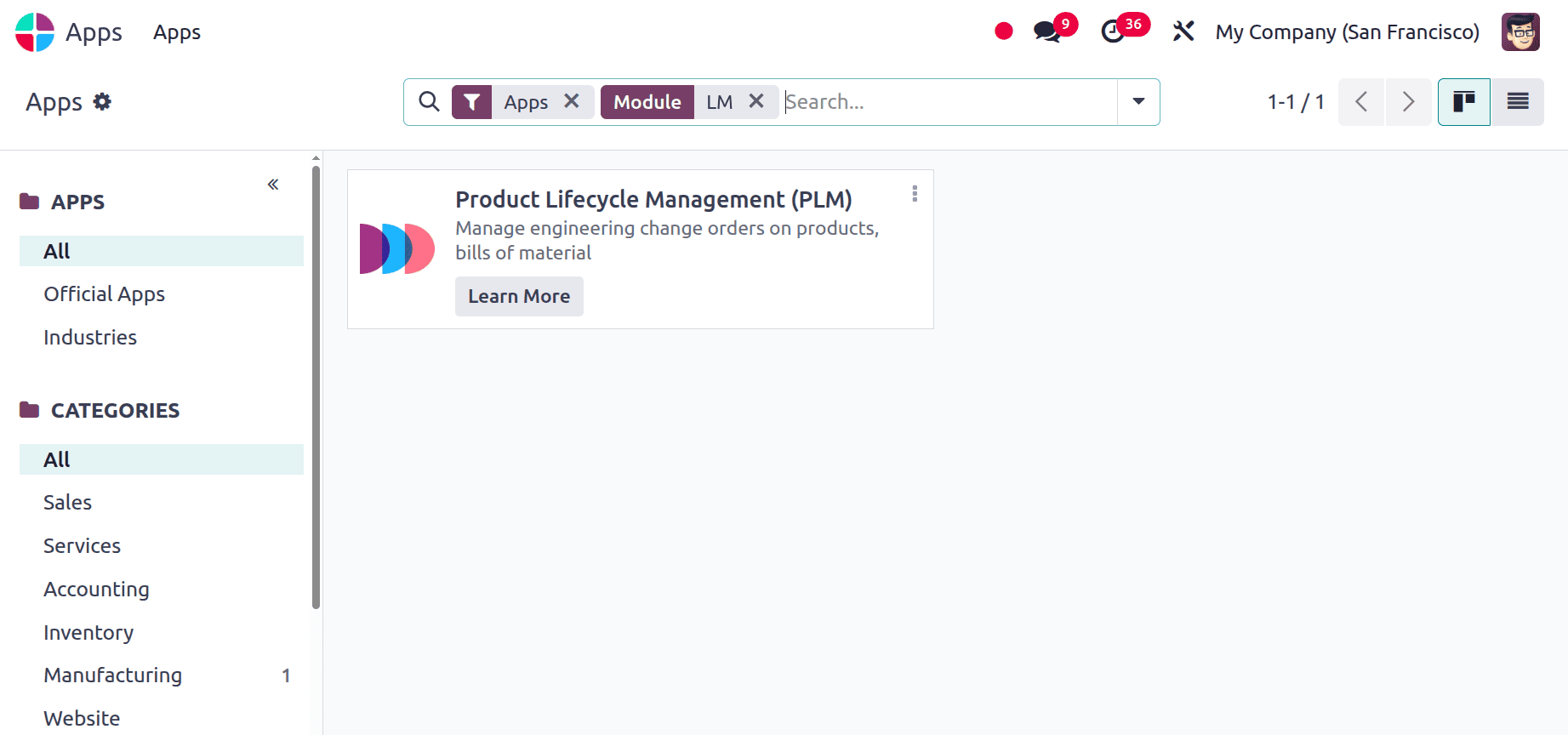

First, go to the Apps and install the PLM module, which is the Product Lifecycle Management module. Install the module first.

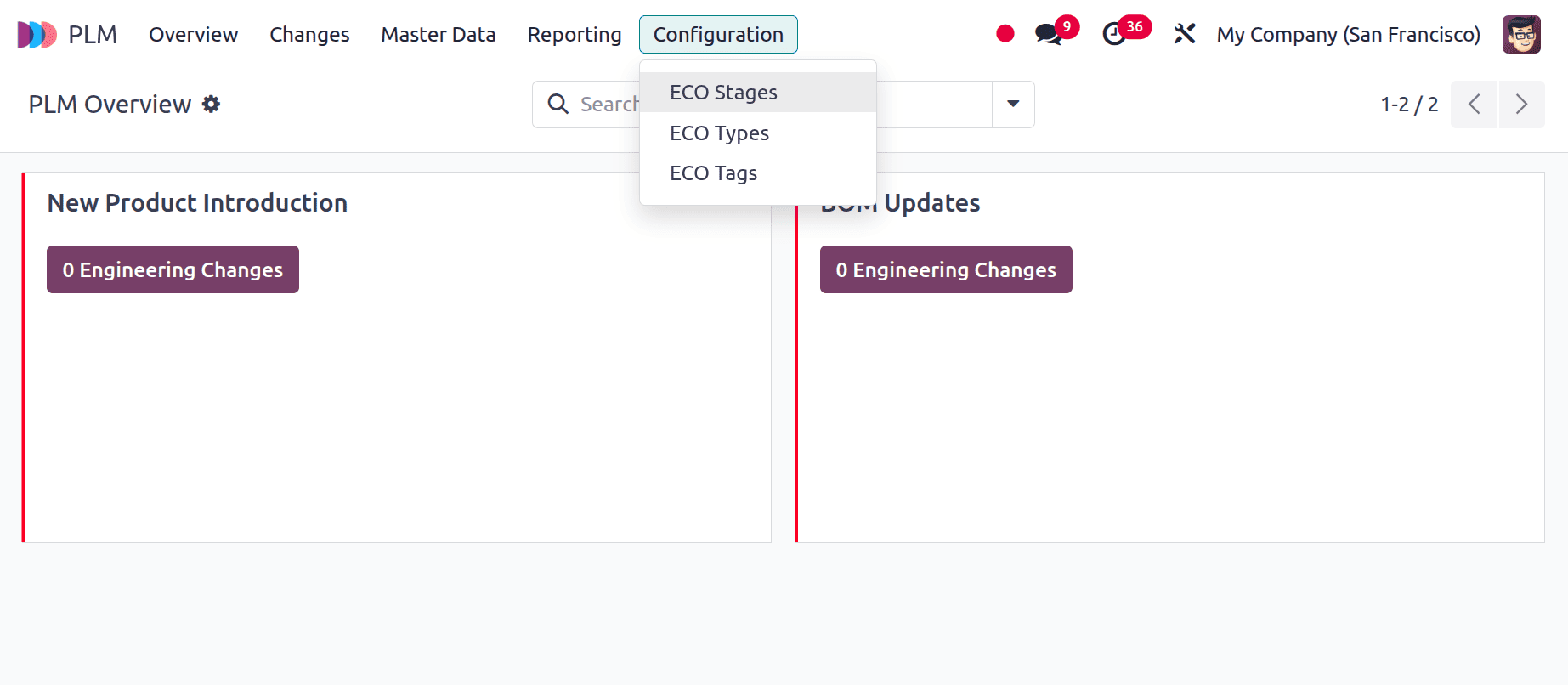

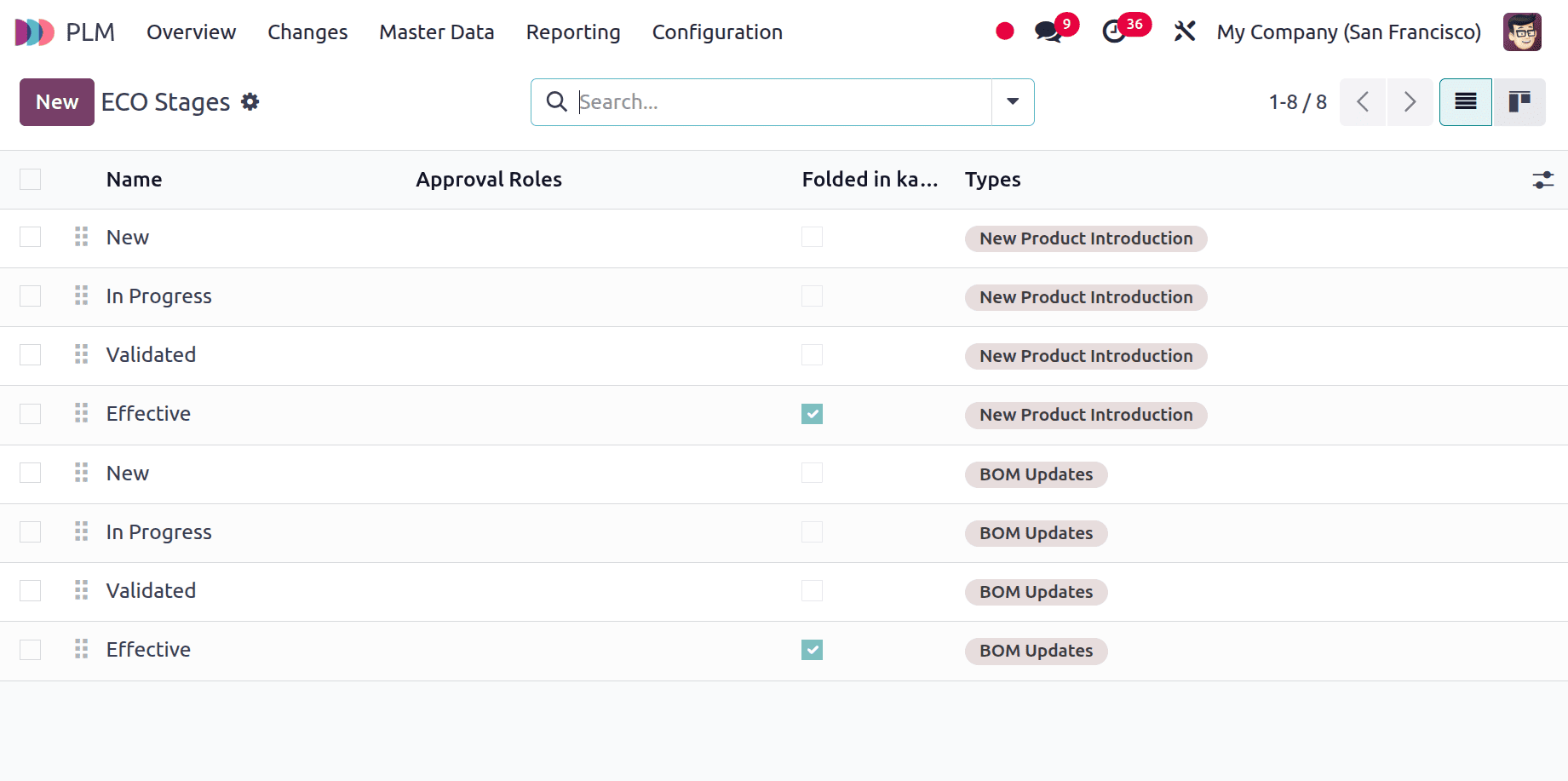

Then open the module. The dashboard shows ECO Types. There are 2 ECO Types: New Product Introduction and BoM Updates. Choose the ECO Stages from the Configuration menu.

A list of stages is provided; you can either choose one or create a new one. To add a new one, click on the New button.

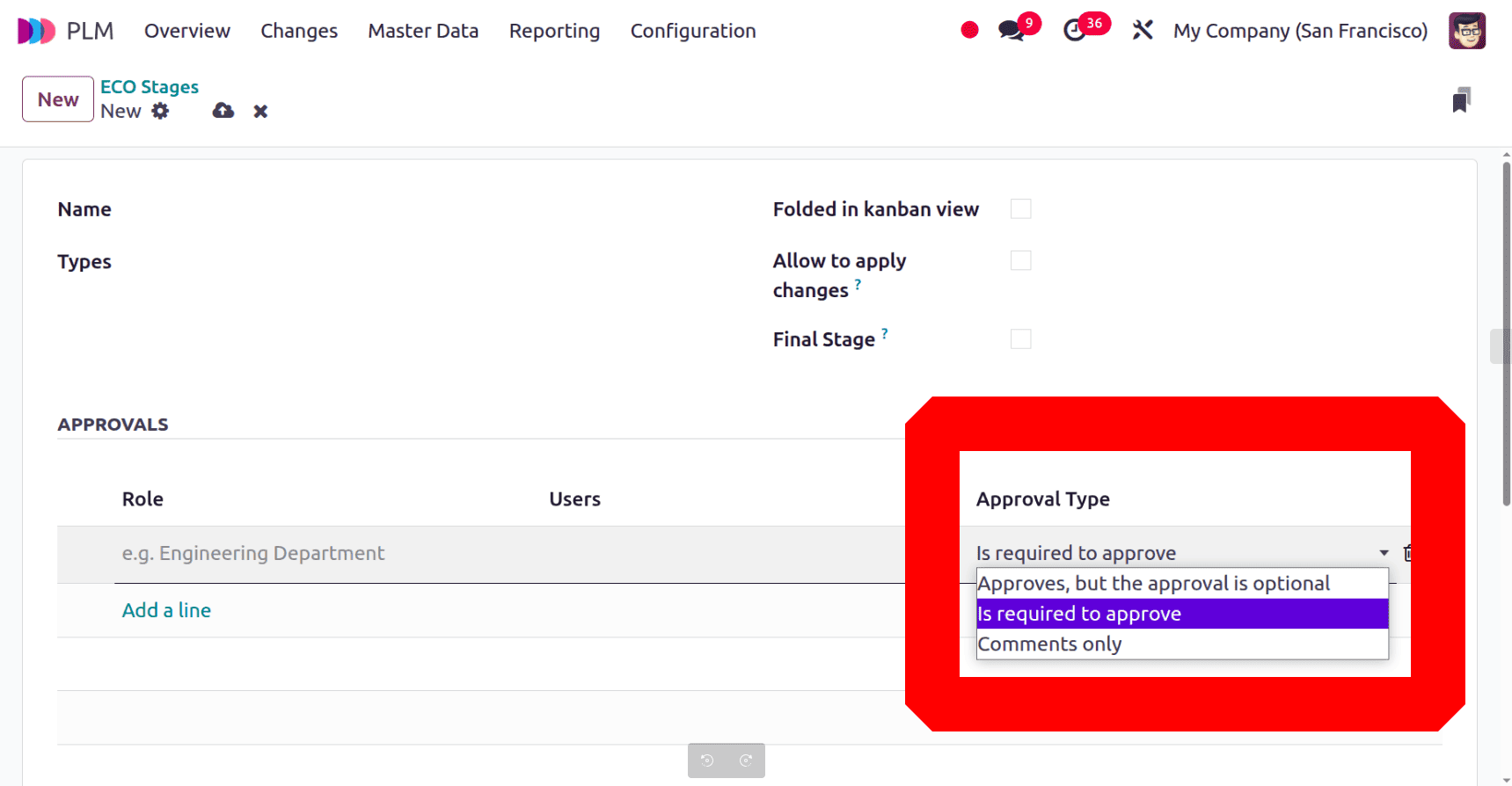

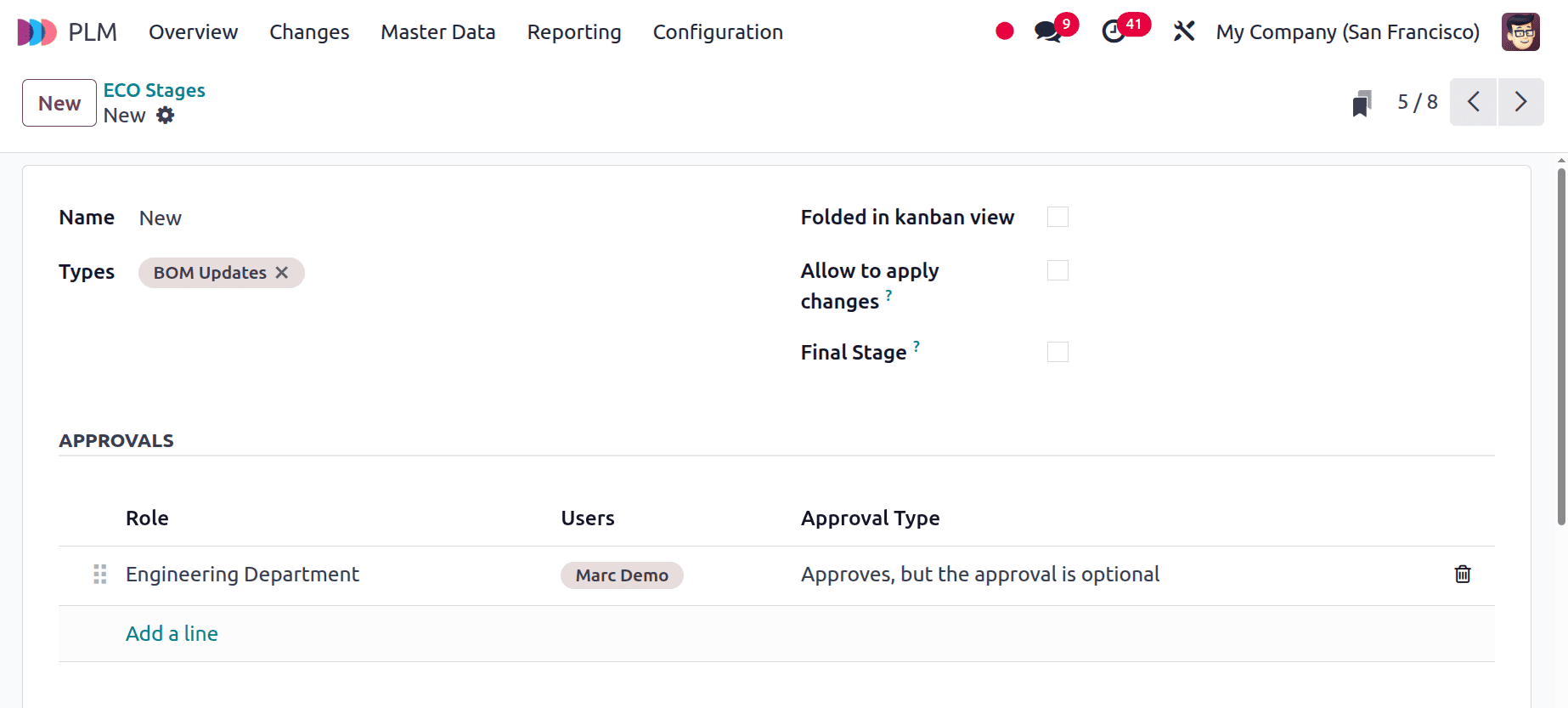

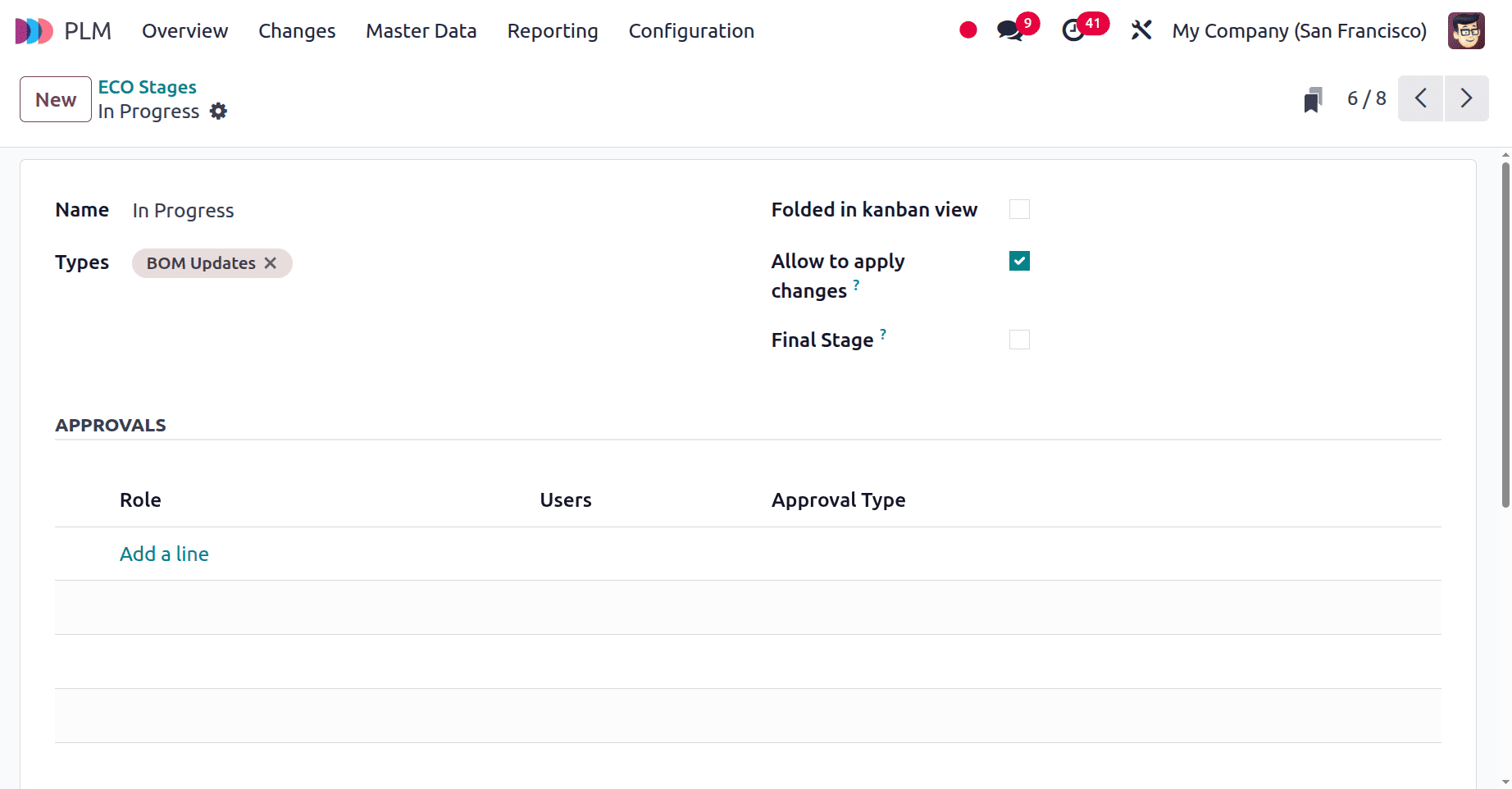

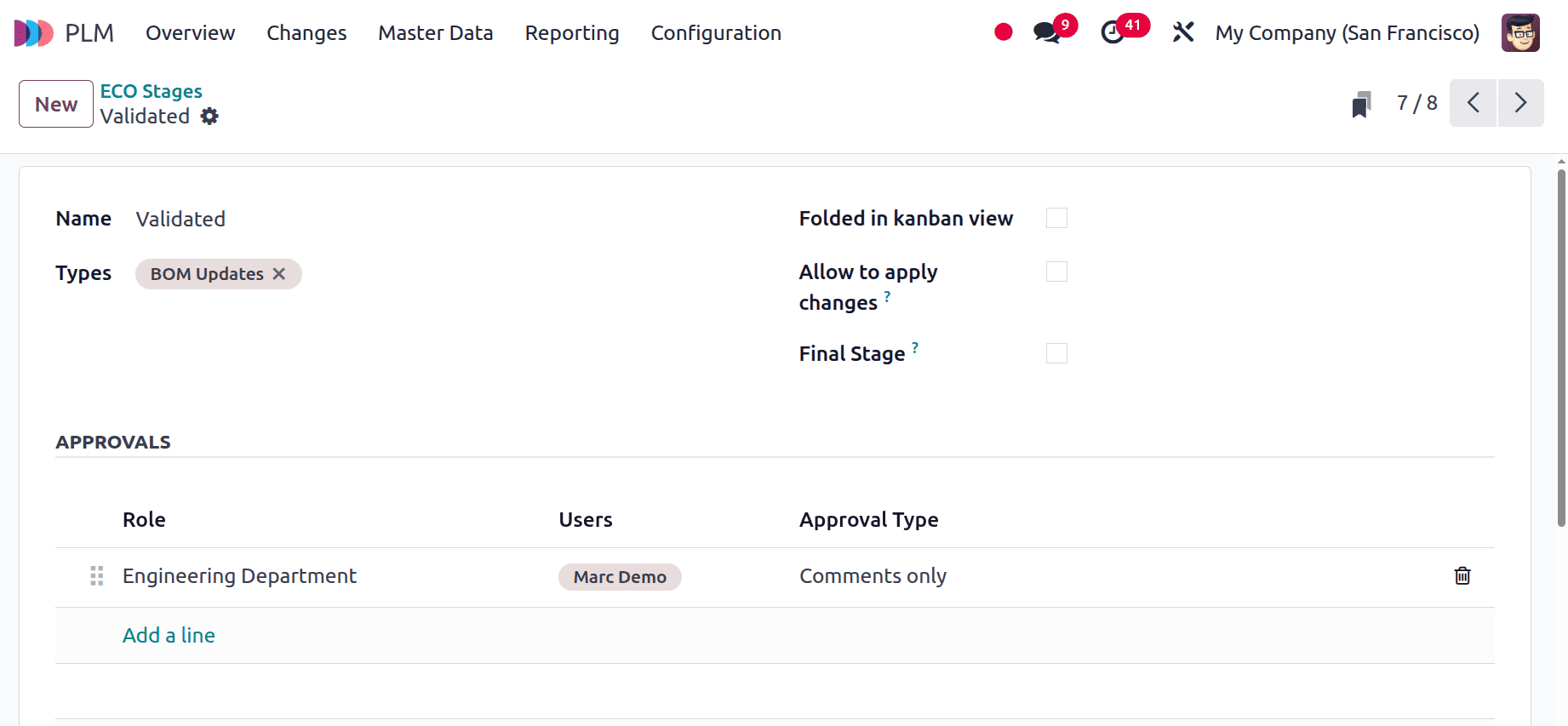

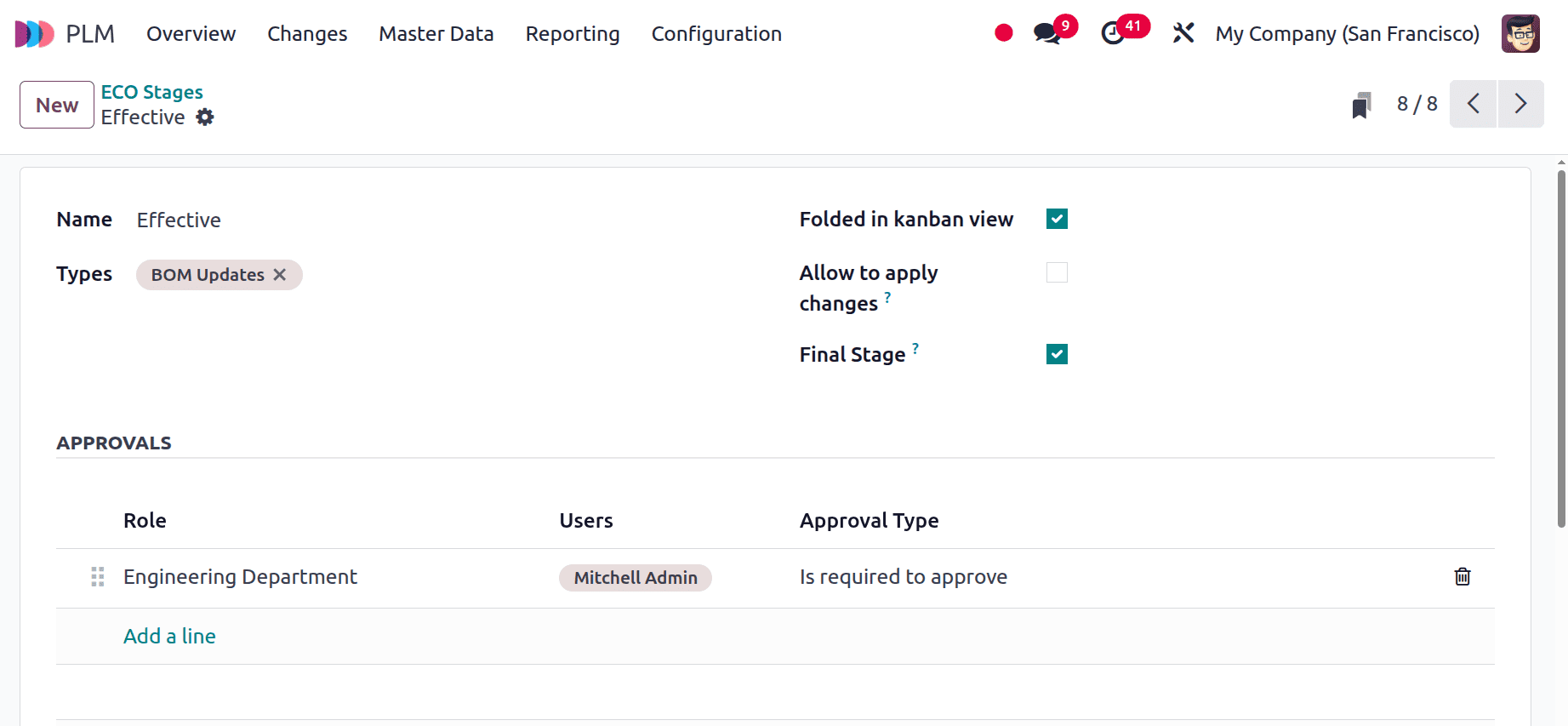

When clicking the new button, the user should first add the Stage name and then choose the ECO Type. To fold the stage in Kanban view, enable the checkbox Folded in Kanban view. If the user wants to apply the added changes at this stage, enable the Allow to apply changes checkbox. If the created is a final stage, enable the checkbox Final stage.

Inside the APPROVALS section, add the Role, Use, and choose the Approval Type. There are three types of approvals.

- The first one is “Approval, but the approval is optional”. Which means the users can approve, but the approval is not mandatory; users can skip the approval and move to the next stage.

- The second one, “Is required to approve”, which means the approval from the assigned user is mandatory. Without getting the approval from the assigned user, you can't move to the next stage.

- The third one is “Comments only”. In this, the assigned user's comment is considered approval.

Here, the first stage is named New, and the type is Bom Updates. The approval is set as “Approval, but the approval is optional”. The user is Marc Demo. Other checkboxes, Folded in kanban view, Allow to apply change, and Final stage are not enabled.

The second stage for the type BoM Updates is named In Progress. The checkboxes Folded in the kanban view and Final stage are not enabled. But allow changes to apply changes enabled, which means the changes on BoMares are added and applied in this stage. No approval set at this stage.

The third stage is validated for the type of BoM Updates. Checkboxes Folded in kanban view, Allow to apply changes, and Final stage are not enabled. And the approval is set as “Comment Only,” and the user is Marc Demo.

The effective stage is the Final stage for the type BoM Updates. Which is the final stage, so the Final stage checkbox is enabled. And the stage should be folded in the Kanban view. Approval is required, and the user is Mitchell Admin.

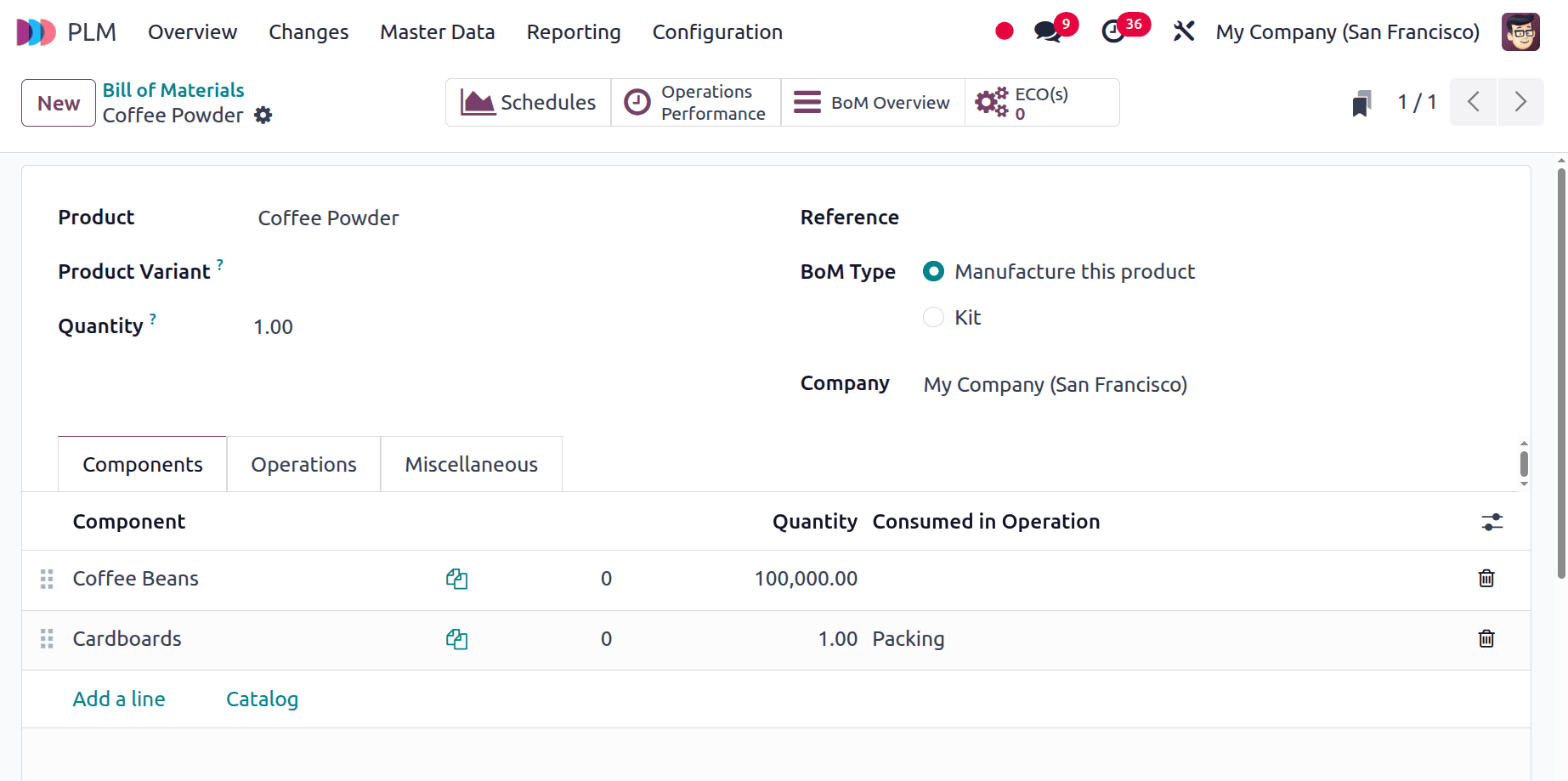

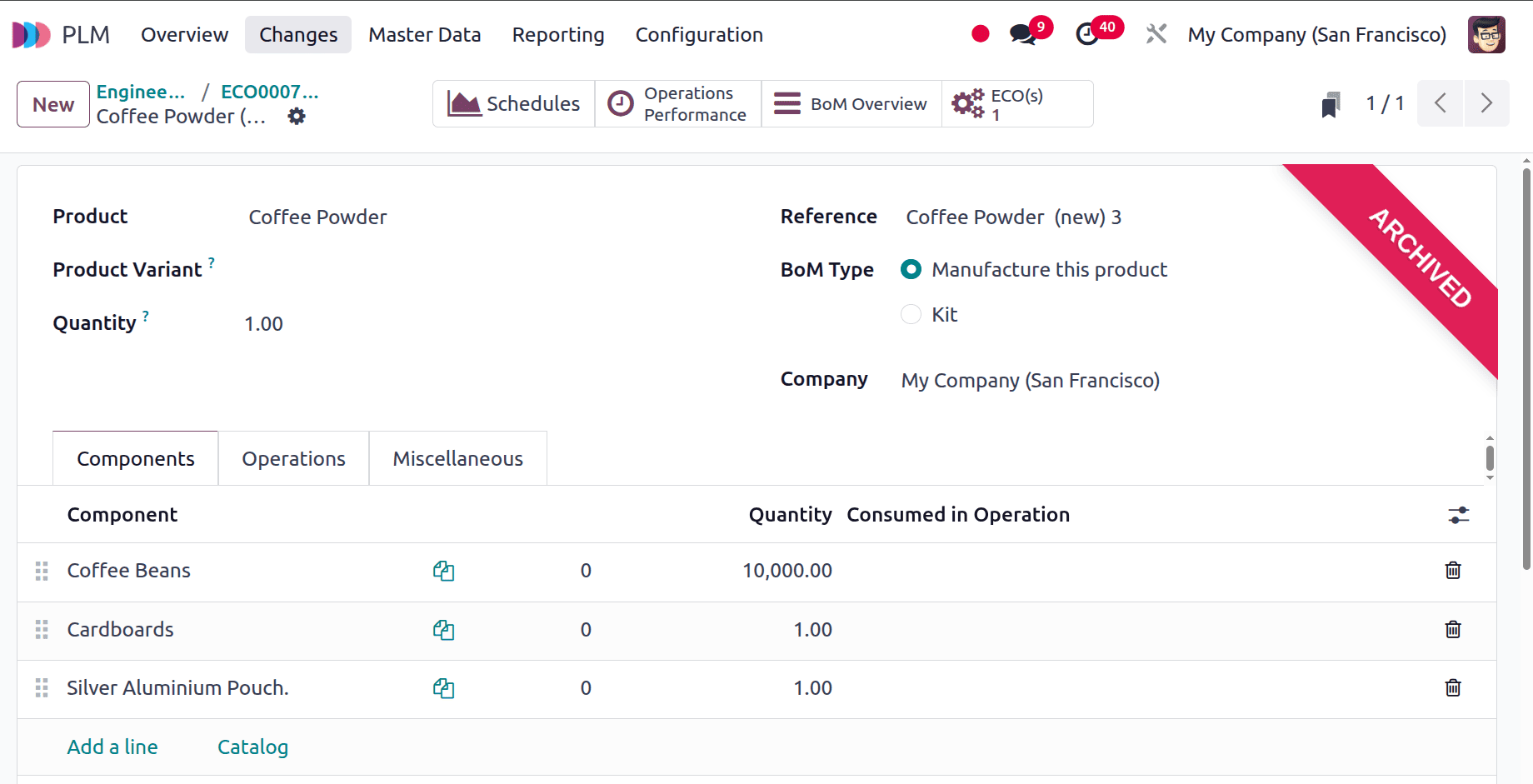

Let's check how this works to create a new bill of materials. Here is the created bill of materials for Coffee Powder. The components are Coffee Beans and cardboard for packing.

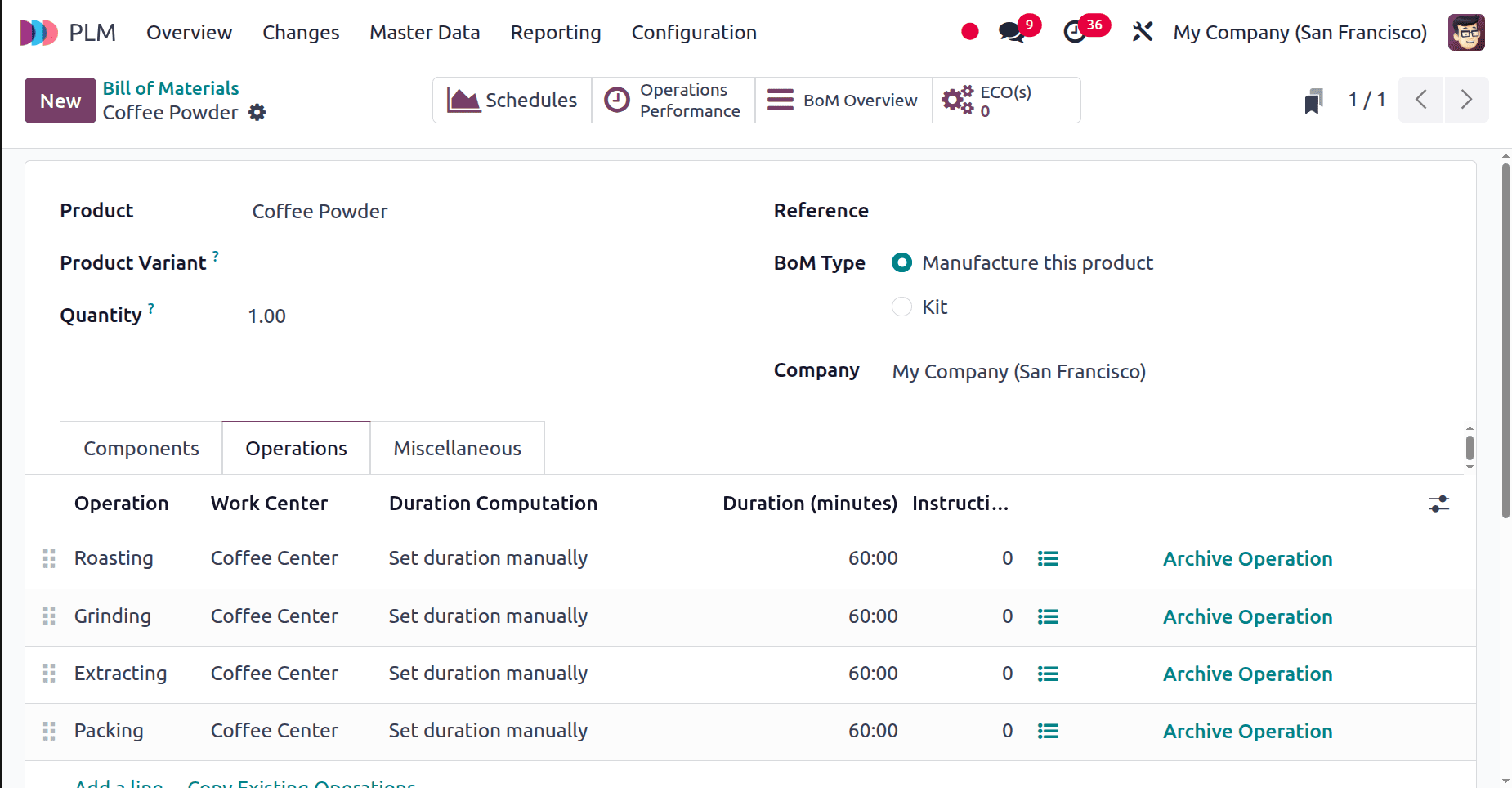

The operations are Roasting, Grinding, Extracting, and Packing.

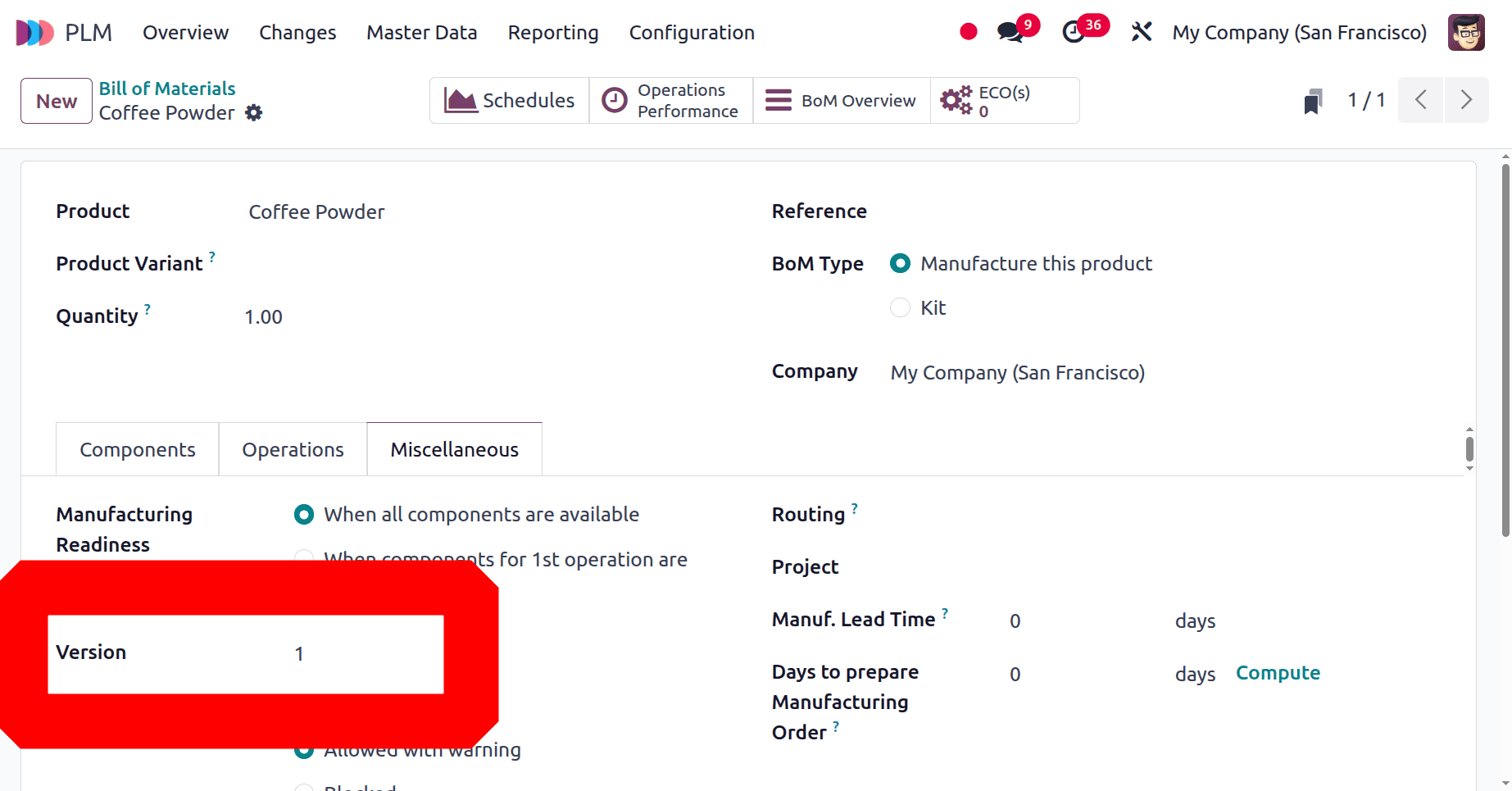

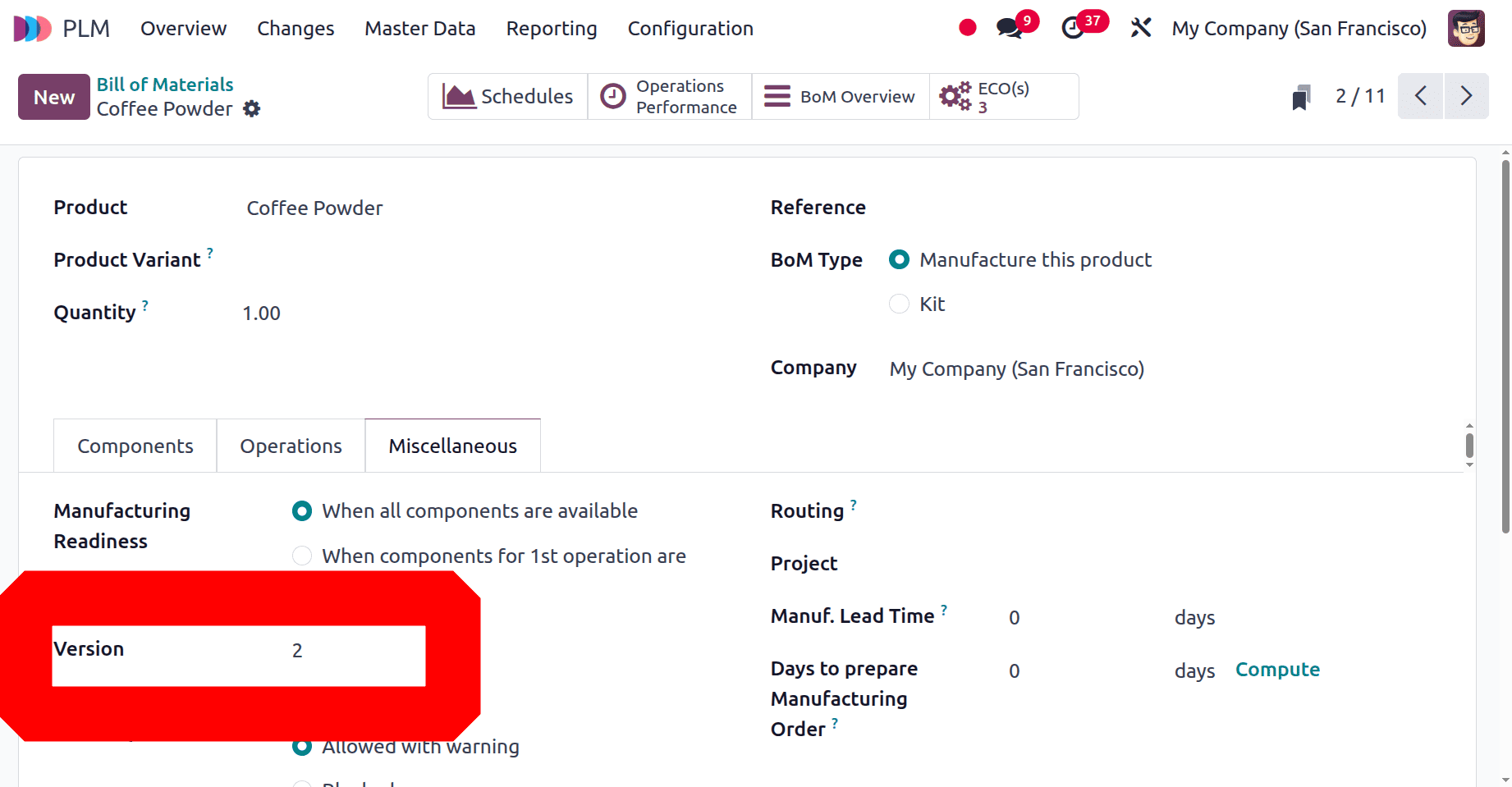

Then the version of the bill of materials is 1. We can see the version from the Miscellaneous tab as shown below.

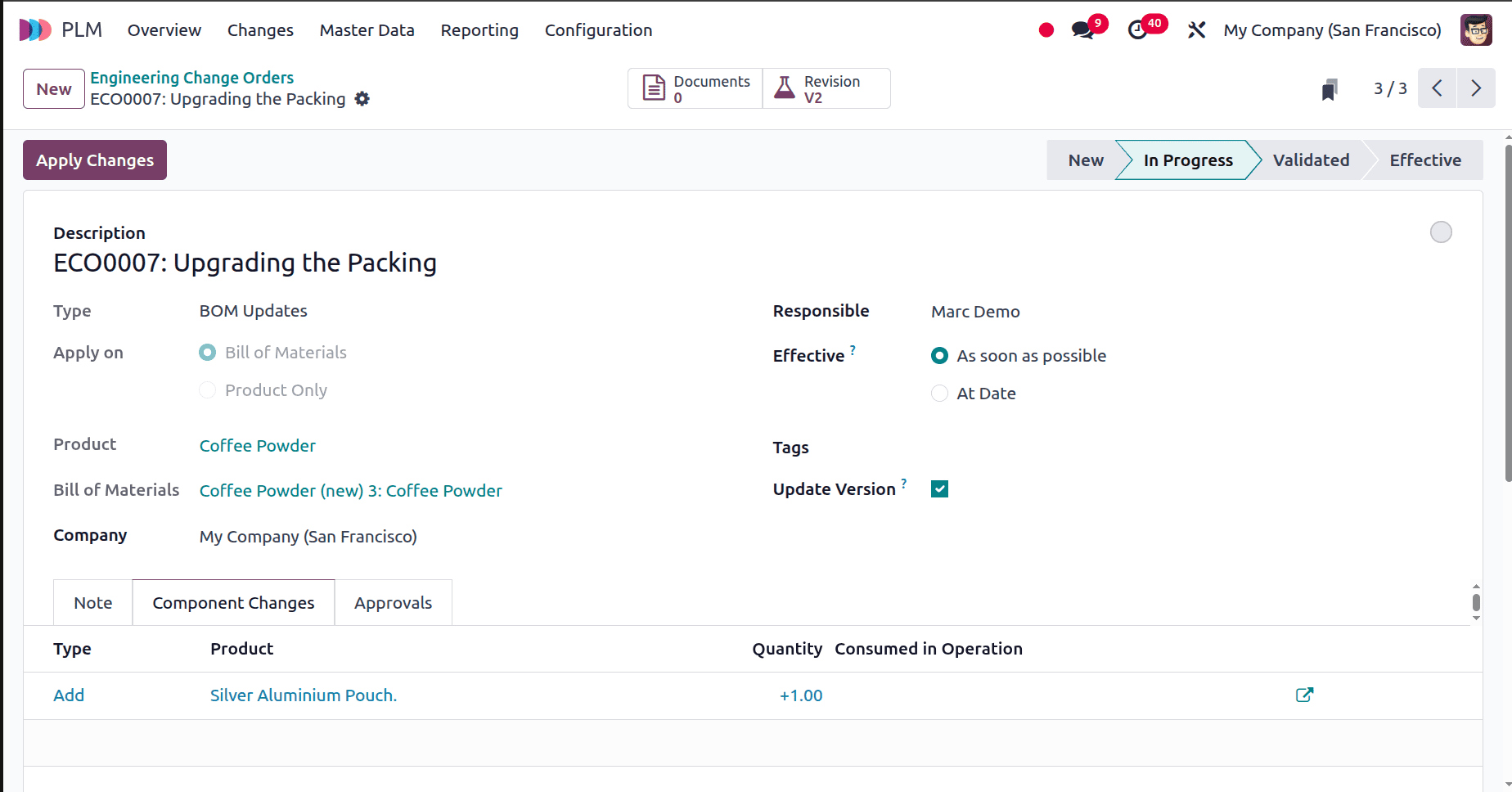

To add Eco changes for the bill of materials, move to the Changes menu. Here, the manufacturers decided to improve the packaging of their product, so they decided to add a Silver Aluminium Pouch.

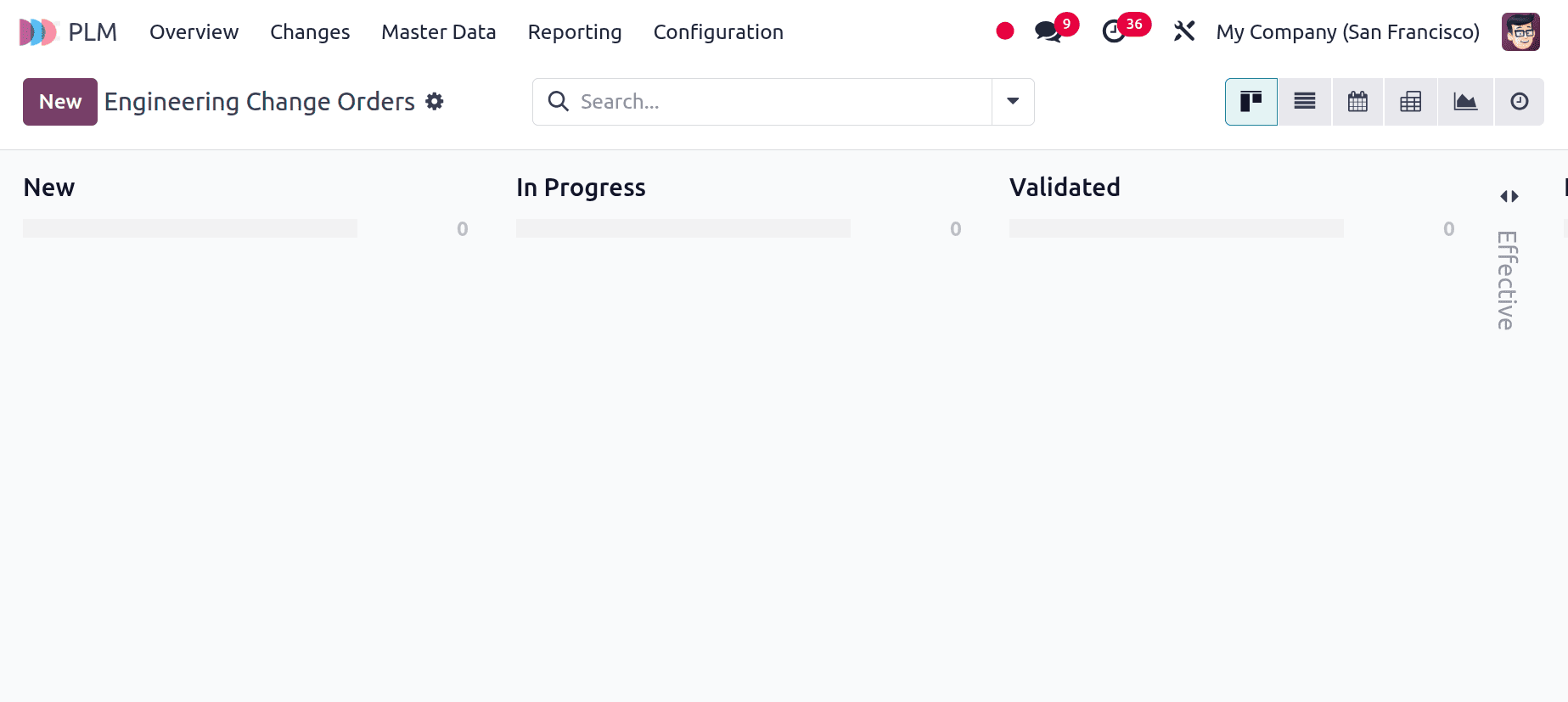

Here, the stages are shown, but the Effective stage is folded in the Knaban view. Click on the New button.

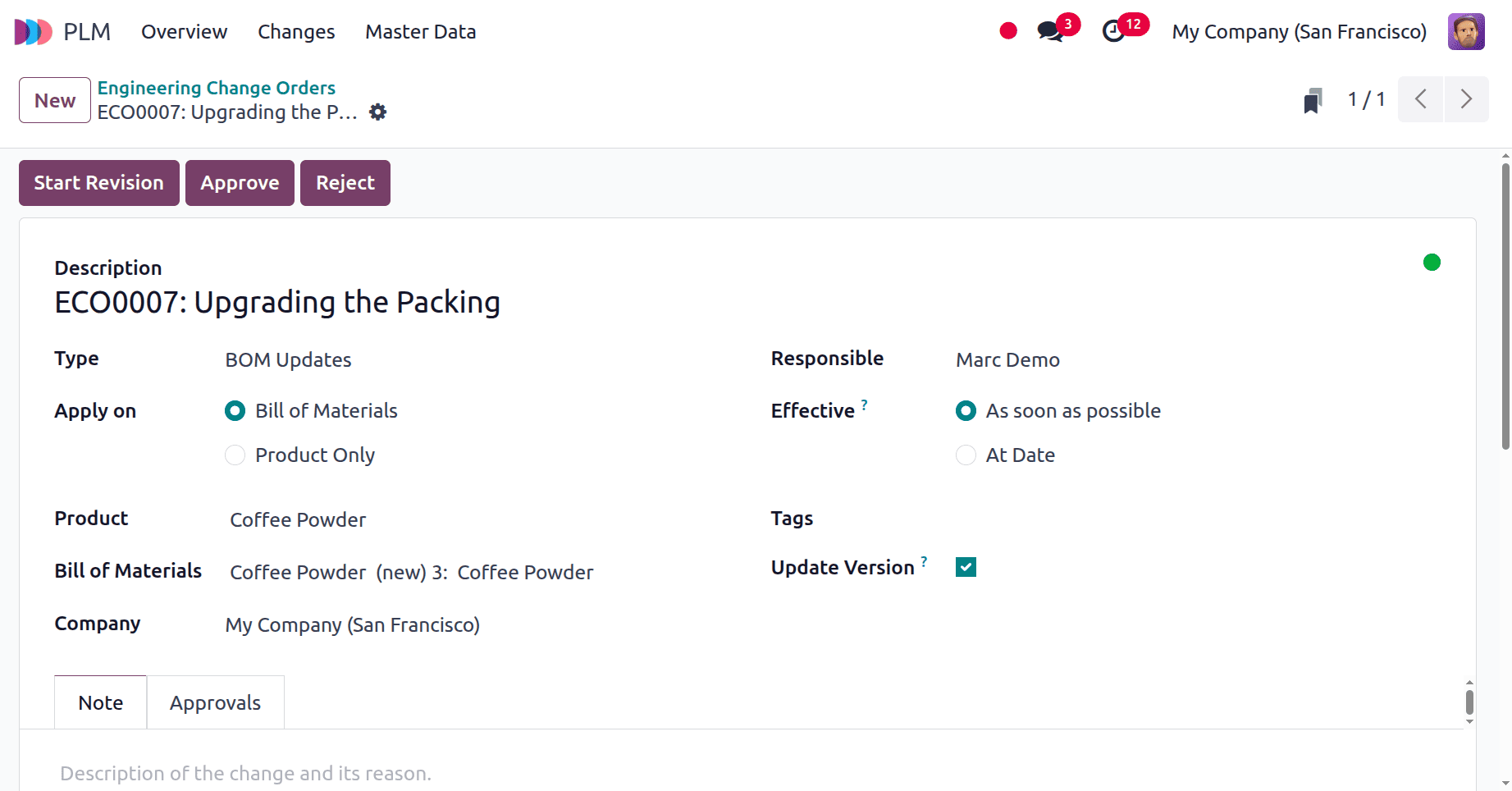

The description given is Upgrade Packing, and the type chosen is the same as BoM Updates. Users can add ECO to the Bill of Materials and the product. Here, the ECO is applying the BoM, and the Bill of Materials is chosen. If the check box Update Version is enabled, then the version of the BoM will change. Then click on the Start Revision button.

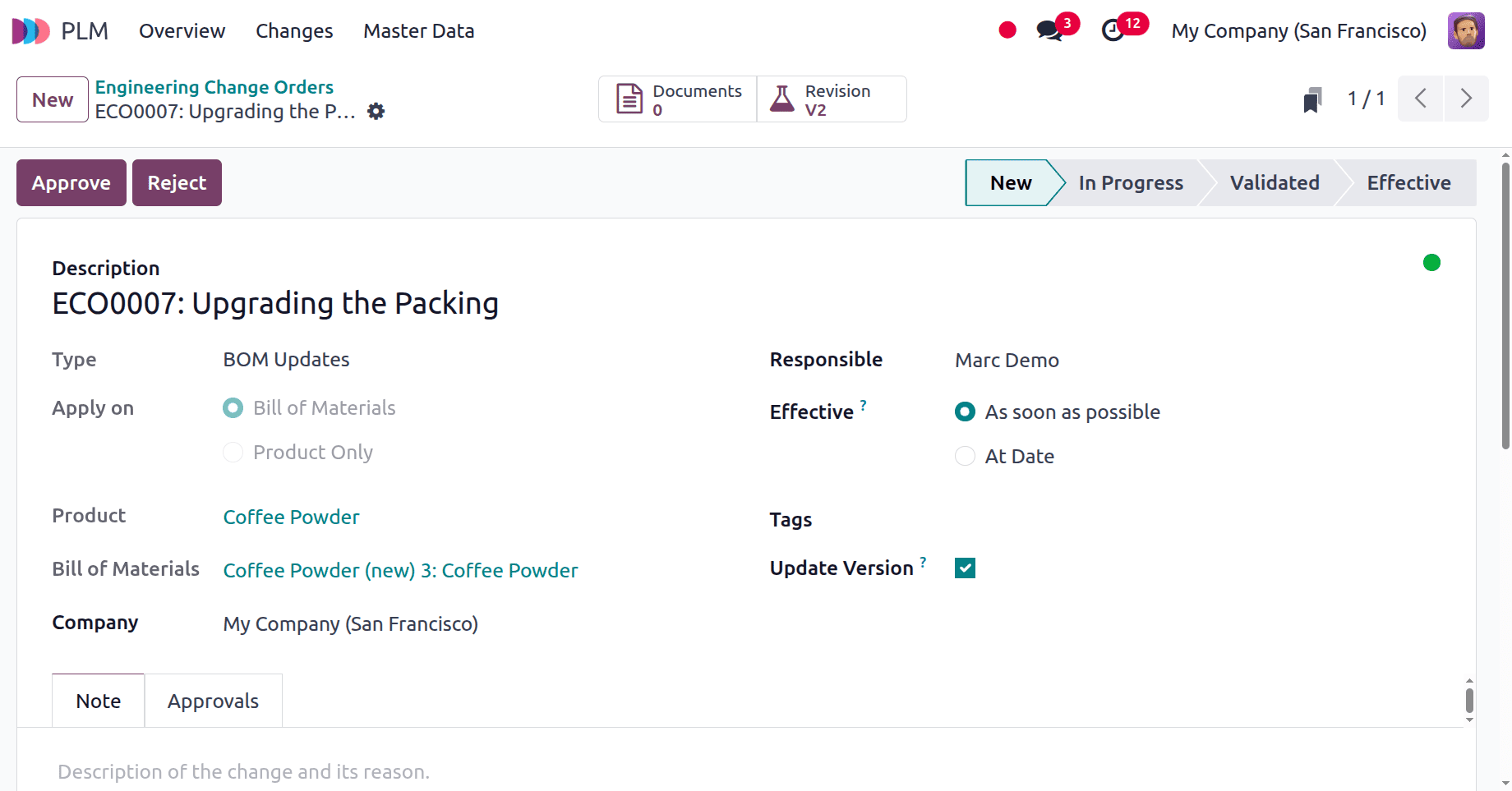

Now the ECO is in a new stage. Under the Approval stage, the first approval can be viewed. Which is “Approval, but the approval is optional”, and the user is Marc Demo. Let's skip the Approval and move to the next stage.

Now the second stage is In Progress. Click on the Revision smart tab. The bill of materials is in the Archived stage now.

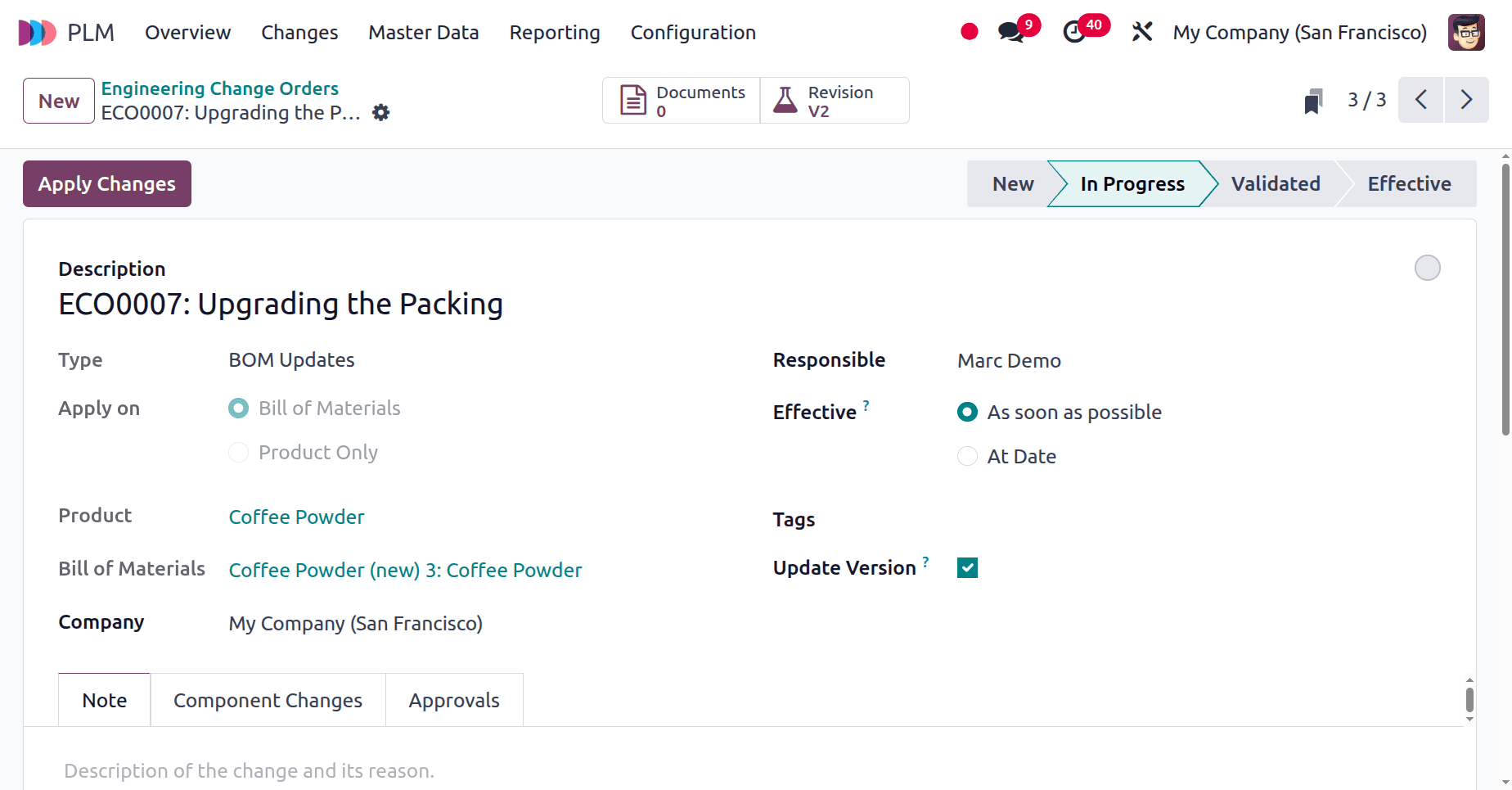

A new component, Silver Aluminium Pouch, has been added. Then move back to the ECO.

Now, a new component is added. A new tab has been added inside the ECO, named Component Changes. The new component was updated there. Click on the Apply Changes button to update the change. Then click on the Apply Changes button.

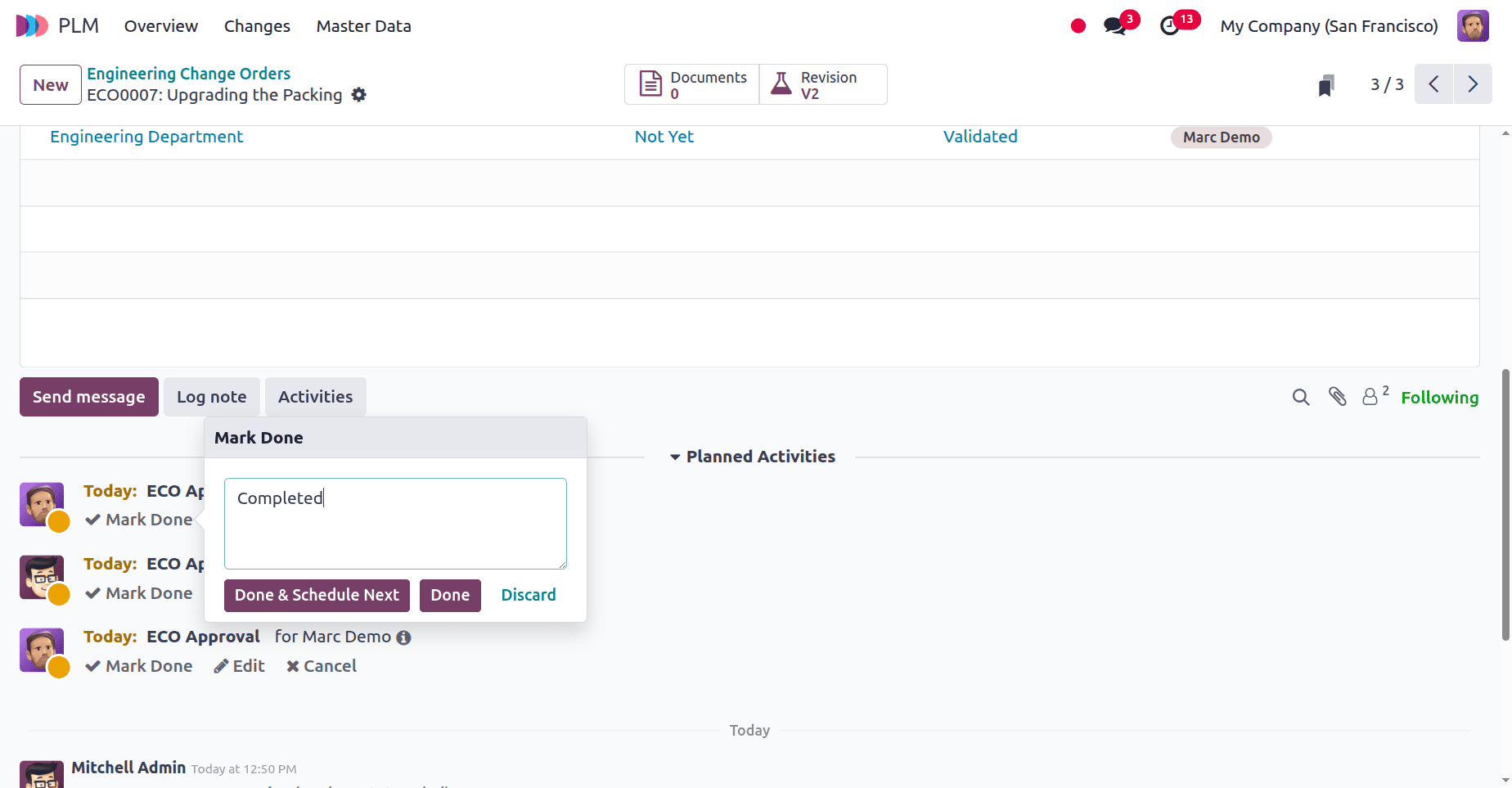

The next stage is Validated, and employee approval is needed. The comment only is the approval type, and the user is Marc Demo. Add a comment, then click on the Done button, and add a comment as shown below.

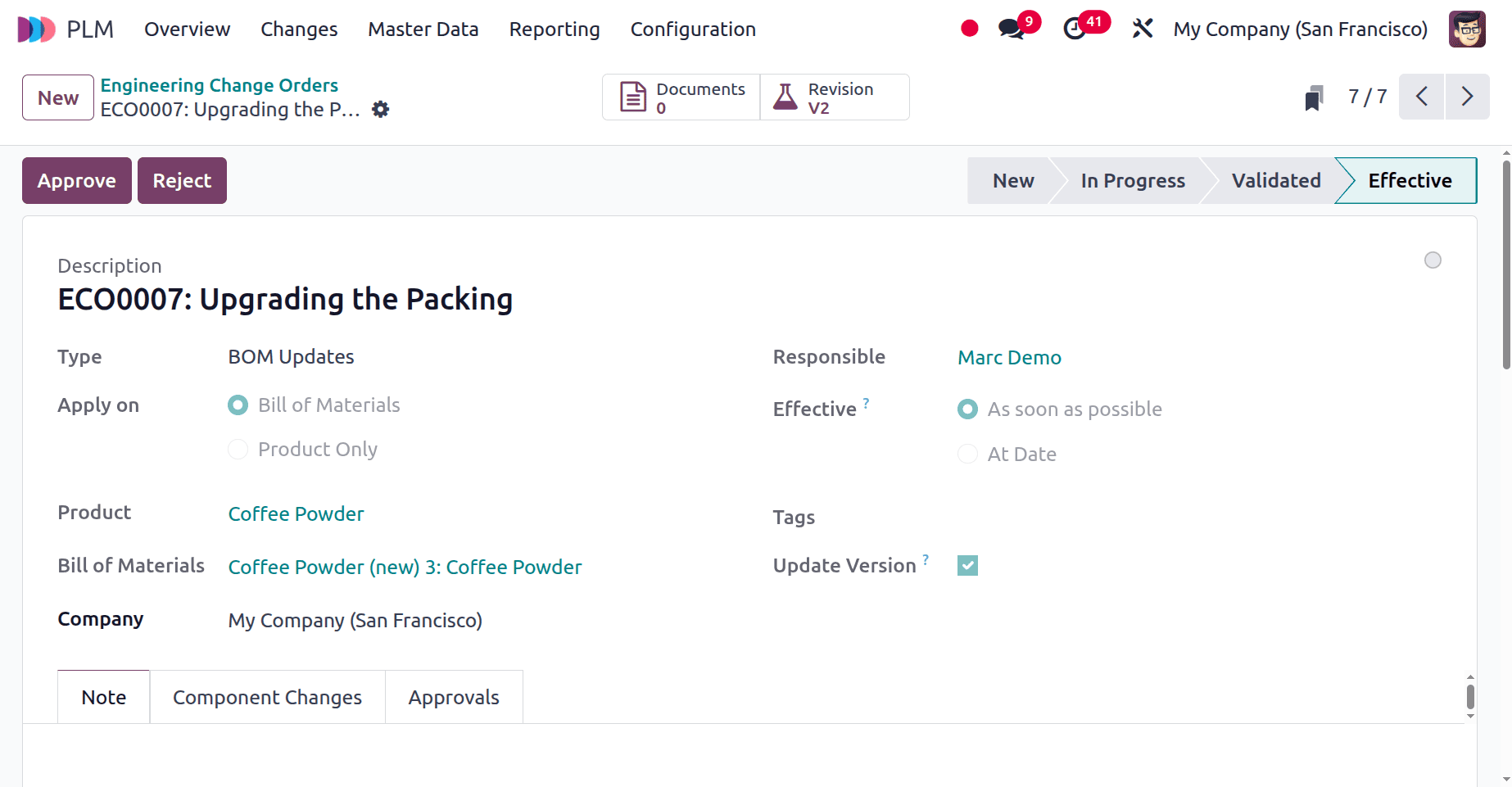

The next stage is Final, and Approval from the Mitchell Admin is needed in this stage. The approval is mandatory, so click on the Approve button.

Note that the Engineering Change order for the Bill of Material for Coffee Powder is complete, and the version of the BoM has also changed.

So this is how the ECO stages are configured and managed in the Odoo 18 PLM module.

To read more about How to Configure ECO Types and ECO Stages in Odoo 18, refer to our blog How to Configure ECO Types and ECO Stages in Odoo 18