In any business that deals with physical goods, maintaining the right inventory levels is a constant balancing act. Too much stock ties up capital and storage space, while too little leads to stockouts and customer dissatisfaction. Odoo 18's Replenishment Report is a vital feature designed to solve this challenge. It enables businesses to make data-driven decisions when it comes to restocking products, ensuring a smoother supply chain and better inventory control. The report offers real-time visibility into stock requirements and highlights products that need replenishment, allowing managers to act quickly and efficiently.

The Replenishment Report in Odoo is particularly useful because it takes multiple factors into account when recommending restocking actions. It doesn't just look at current inventory levels; it also considers sales history, demand forecasts, supplier lead times, and even product-specific reordering rules. This comprehensive analysis helps avoid two major inventory issues, overstocking and stockouts. As a result, businesses can maintain optimal stock levels, which translates to reduced operational costs and improved order fulfillment rates. The overall efficiency of inventory operations improves significantly when such intelligent replenishment processes are in place.

A key strength of the Replenishment Report is its seamless integration with other Odoo modules such as Sales, Purchase, and Manufacturing. For instance, when a product reaches its minimum stock level, the system can automatically trigger a purchase order or manufacturing order based on the product’s configuration. This inter-module communication ensures that procurement activities are in sync with real-time sales data and customer demand. Odoo supports two primary methods for handling product replenishment: Reordering Rules and the Make to Order (MTO) route. Reordering Rules are set directly on a product and allow businesses to define minimum and maximum stock levels. When the quantity available drops below the minimum level, Odoo automatically flags the product for replenishment in the report. On the other hand, Make to Order is a more dynamic method where purchase or production orders are created only when a sales order is confirmed. This approach is useful for custom products or businesses that prefer not to keep certain items in stock.

How to Directly Replenish a Product in the Inventory Module in Odoo 18

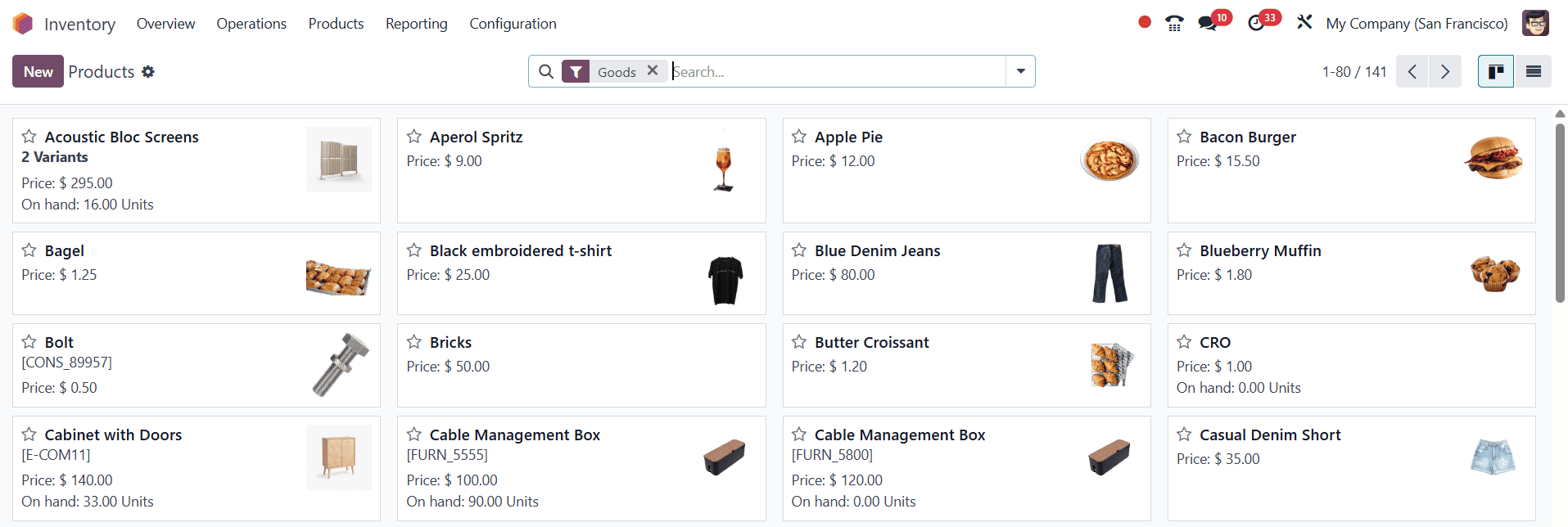

Replenishing a product directly within the Inventory module of Odoo 18 is a simple yet powerful process that enables businesses to maintain consistent stock levels and avoid operational disruptions due to stockouts. To begin, log in to your Odoo instance and navigate to the Inventory module from the main dashboard. Once inside the module, access the Products menu, which allows you to view and manage all the items listed in your inventory.

From this list, select the specific product you wish to replenish. For illustration purposes, let’s consider the product “Lunch Box”, which currently has zero stock available.

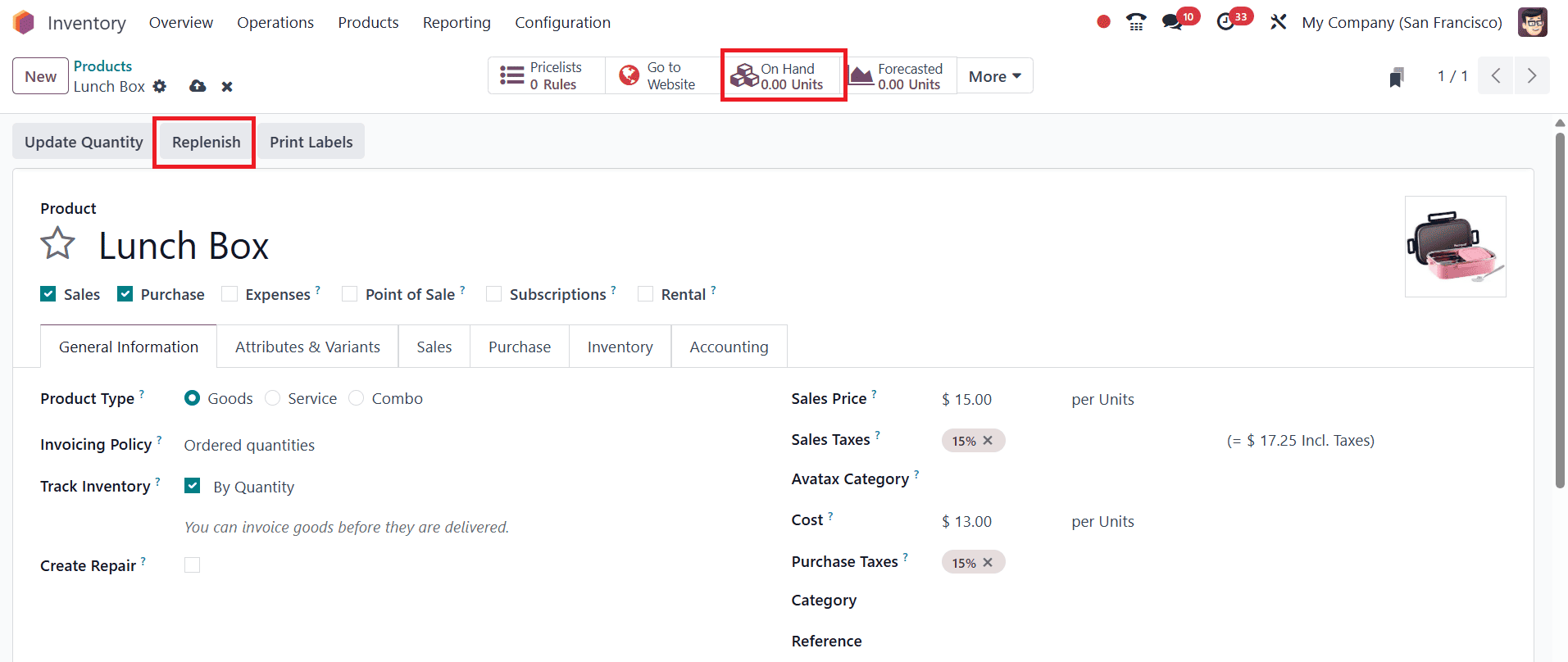

When you open the product form, the On Hand quantity will be displayed, showing the real-time stock availability; in this case, it appears as “0”.

Within the product form, Odoo provides a “Replenish” button. Clicking this button initiates the replenishment process. Upon clicking, a form appears, allowing you to input key replenishment details.

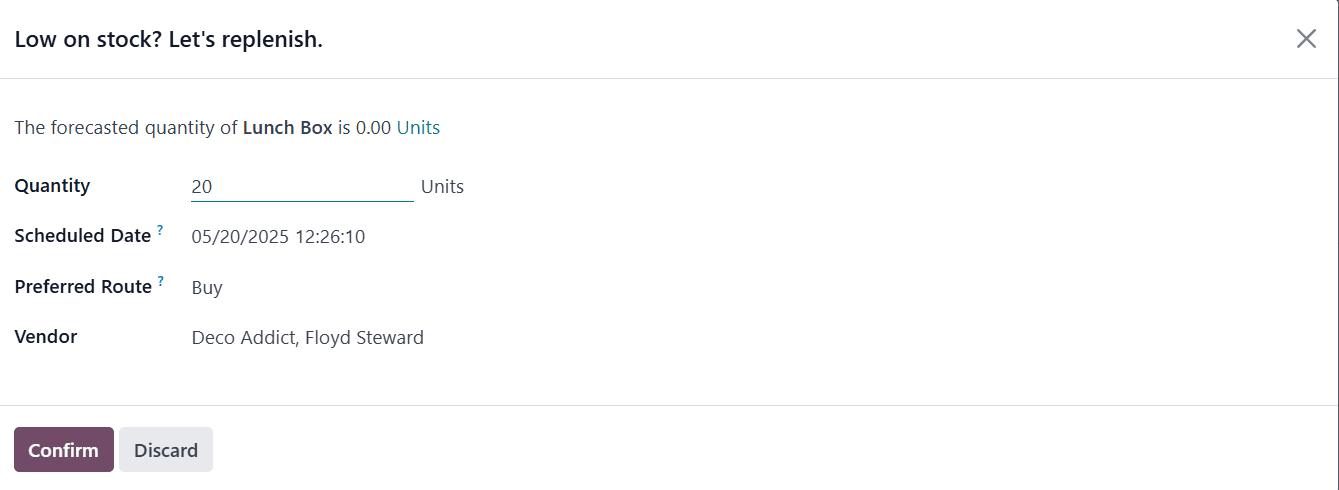

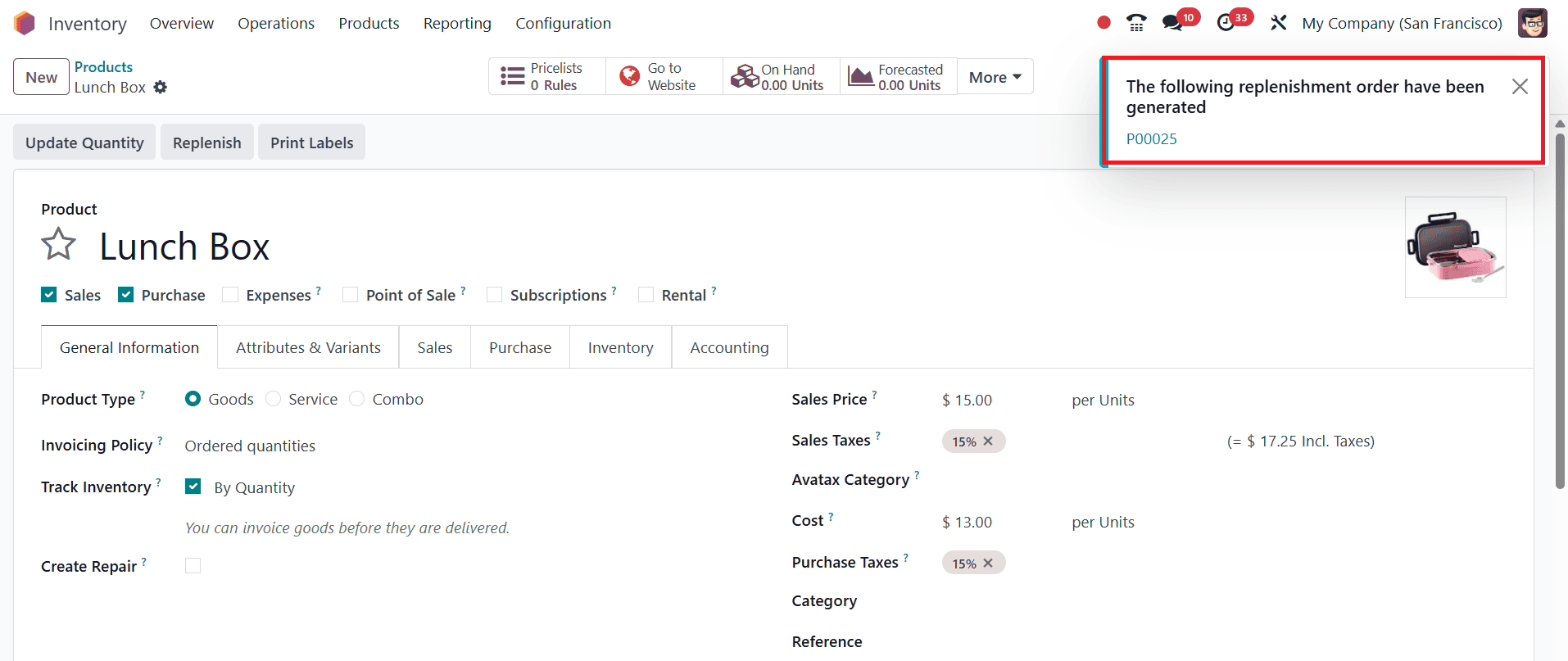

You need to specify the Quantity of the product you wish to reorder. Additionally, you can view and edit the Scheduled Date, which indicates when the replenishment is intended to take place. An important field in this wizard is the Preferred Route, which determines how the replenishment will be carried out. While the system usually follows the default route configured for the product, this field provides flexibility to override it based on current needs. For instance, selecting the Buy route tells the system to generate a purchase order, typically as a Request for Quotation (RFQ). Alternatively, if the route is set to Manufacture, the replenishment action will create a Manufacturing Order. When the Buy route is selected, Odoo automatically links the RFQ to the vendor defined in the product's purchase settings. Once all the details are reviewed and entered correctly, simply click the Confirm button. This action creates a replenishment order, which may appear as a draft purchase order in the Purchase module.

From there, it can be processed further by the procurement team based on approval workflows and vendor responses.

This process of directly replenishing a product from the Inventory module offers a quick and user-friendly way to manage urgent restocking needs.

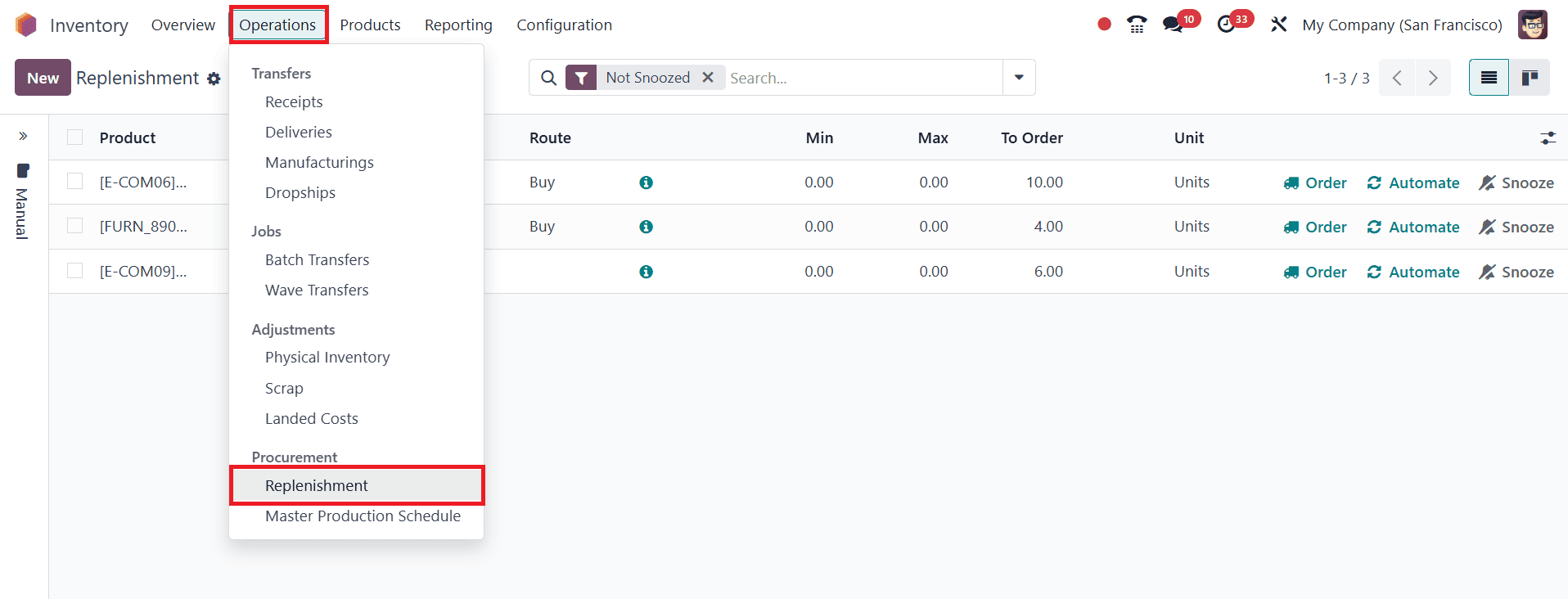

After learning how to create a replenishment order directly from a product form, it's important to understand where these orders are saved and how you can manage them. All the replenishment orders you create will be stored in the Replenishment menu found within the Odoo 18 Inventory module.

This menu acts as a central place where you can view and manage all your product reordering needs.

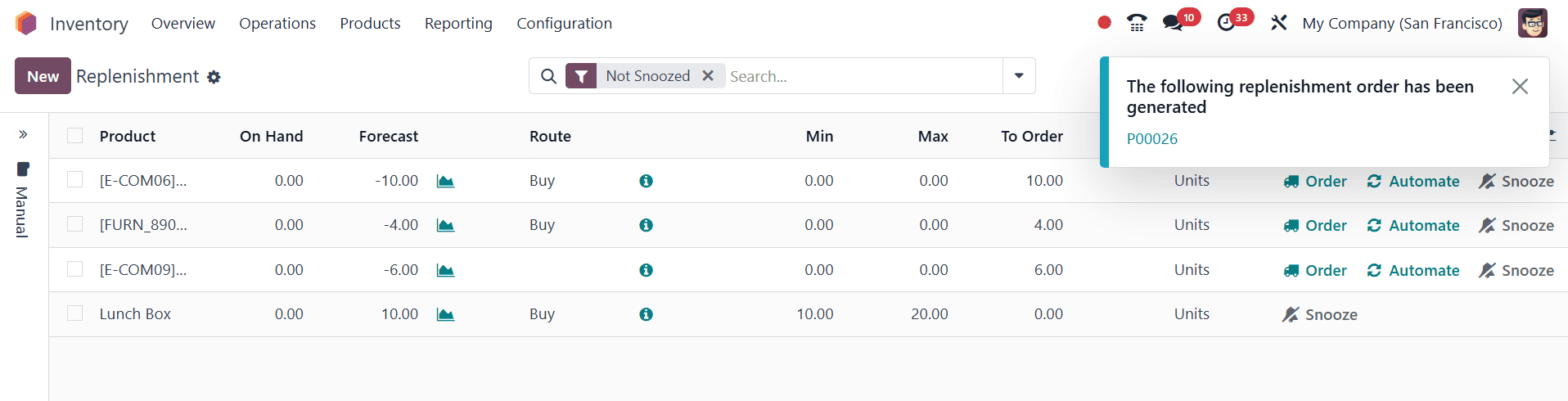

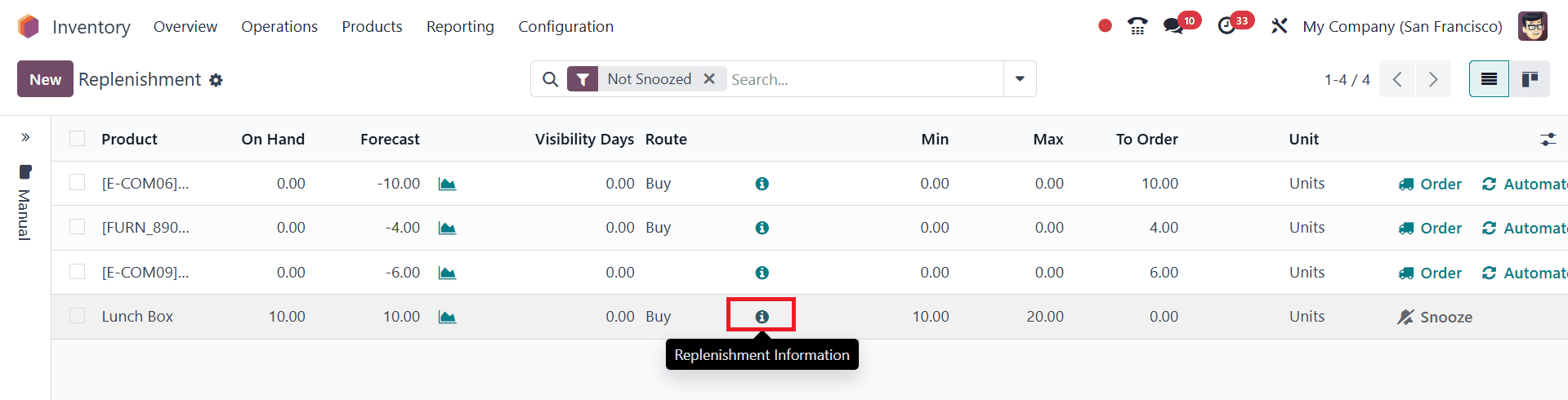

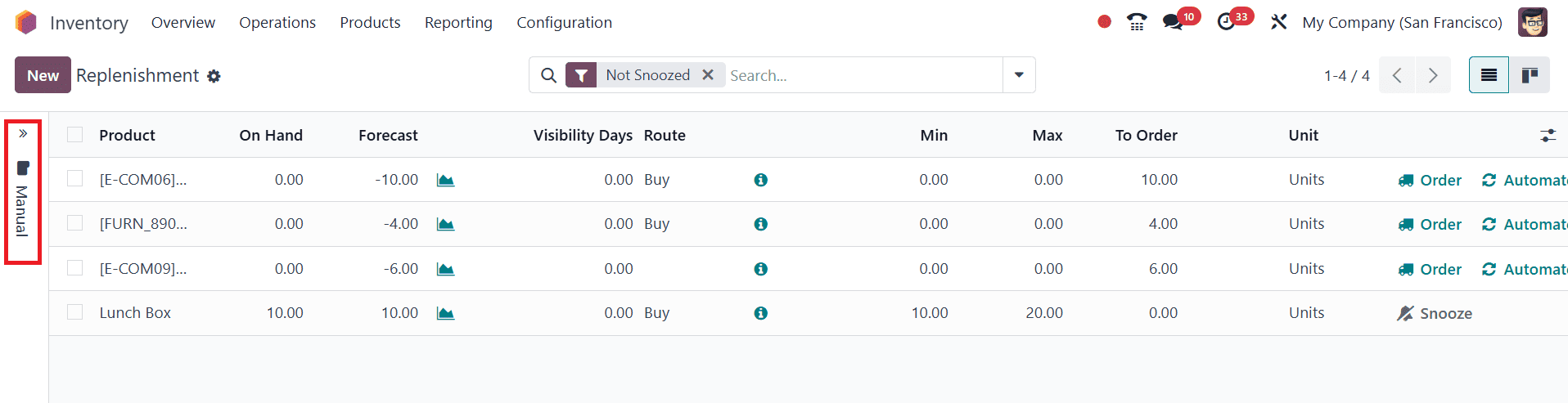

When you open the Replenishment menu, you’ll see a list that displays important details for each product. These details include the Product Name, On Hand Quantity (what’s currently available in stock), and Forecast Quantity (how much is expected to be available based on incoming and outgoing shipments). It also shows the preferred Route (such as Buy or Manufacture), Minimum Quantity, Maximum Quantity, To Order (how much needs to be ordered), and the Unit of Measure (UoM).

If you're looking for a specific replenishment record, you can use the search bar at the top to quickly filter through the list by typing the product name or any related detail.

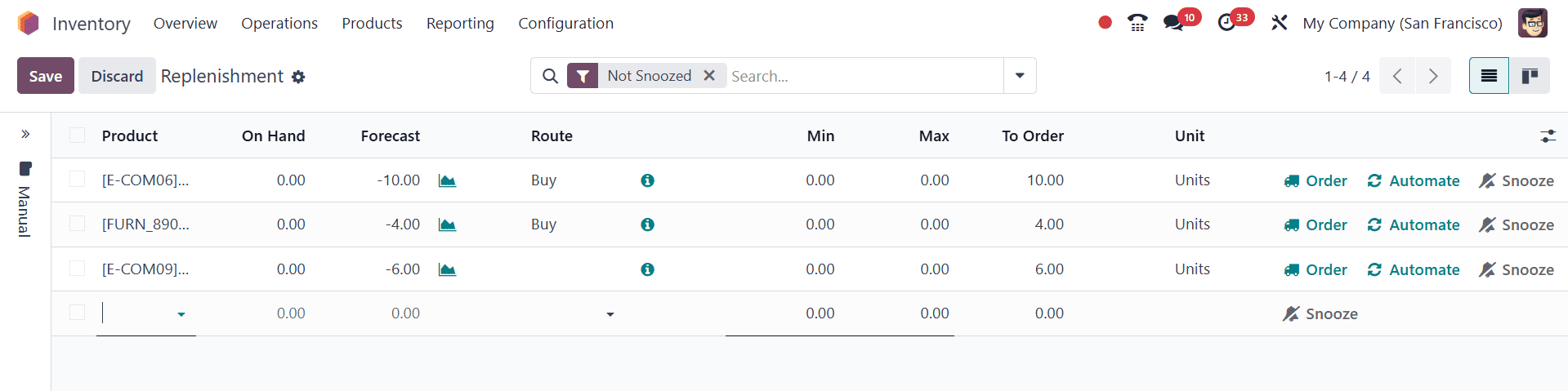

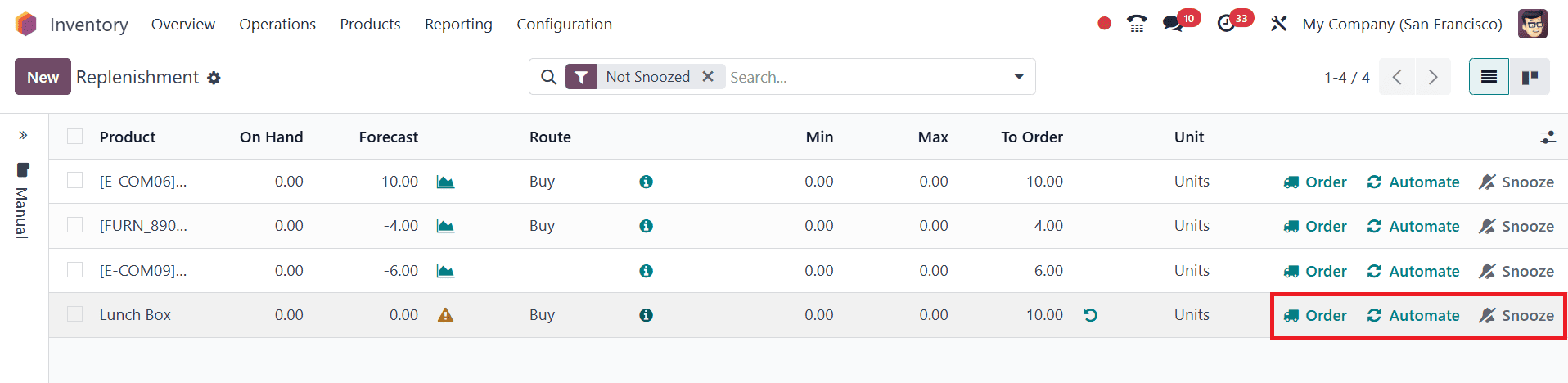

To create a new replenishment entry manually, simply click on the New button. This will open a new blank line where you can enter the required information. Start by selecting the product you want to replenish. Once you choose the product, Odoo will automatically fill in the On Hand and Forecast quantities based on the current data. You can then specify the route for replenishment, for example, you can choose whether the product should be purchased or manufactured.

You can also set Minimum Quantity and Maximum Quantity values. These fields help you control how much stock should be maintained at all times. The Minimum Quantity is the level at which Odoo will recommend a new order, while the Maximum Quantity defines the upper limit to prevent overstocking. At the end of the line, you’ll find two important options: Order Once and Automate. If you choose Order Once, the system will create a one-time replenishment for that product. If you select Automate, Odoo will continue to monitor the product and automatically create replenishment orders whenever the stock falls below the minimum quantity.

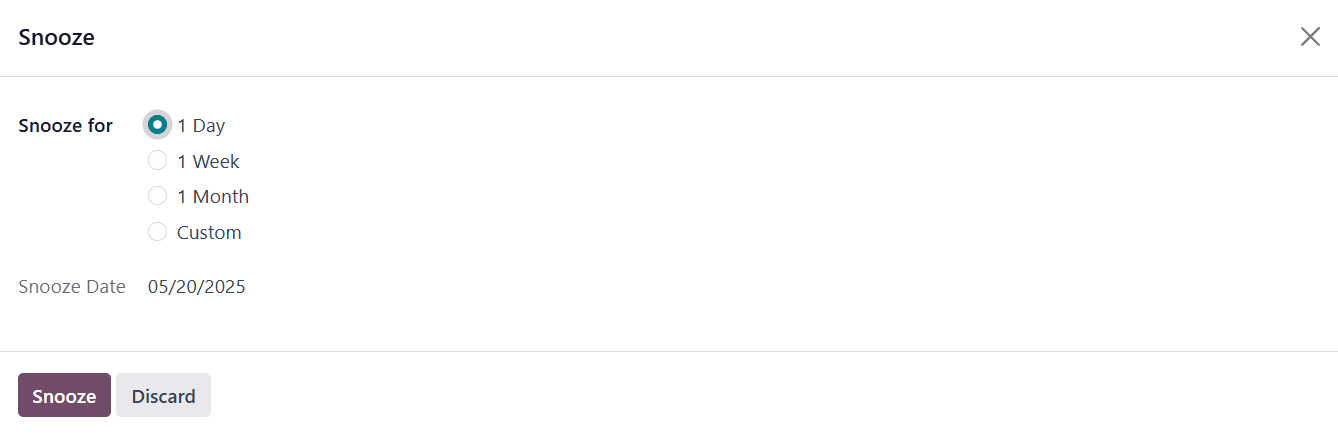

The Snooze option in Odoo 18 Inventory is a useful feature designed to temporarily postpone a replenishment action. When you click the Snooze button next to a replenishment order, a pop-up window appears, allowing you to choose how long you'd like to delay the operation.

You can pick from predefined durations such as 1 Day, 1 Week, or 1 Month, or set a custom date by manually entering it in the Snooze Date field. This gives you complete control to manage your replenishment tasks based on your current priorities and stock strategies.

We created a replenishment order to restock 10 units of the product 'Lunch Box'.

This action will immediately generate a Request for Quotation (RFQ) for the selected product and quantity.

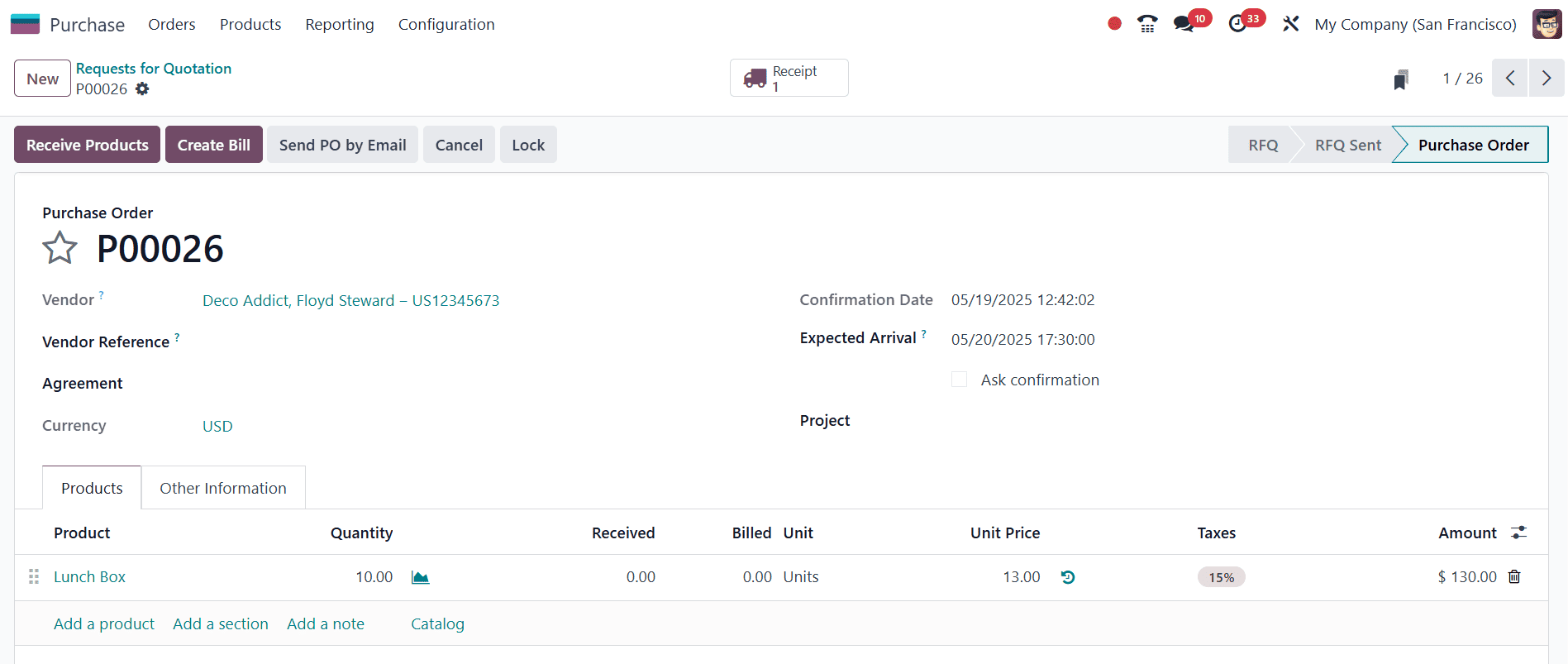

Next, navigate to the Purchase module, where you’ll find the newly created RFQ.

Review the details and convert it into a Purchase Order (PO) once you’re satisfied.

After confirming the purchase order, the next step is to receive the products into inventory. Click the Receive Products button to open the receipt operation. Here, you can verify the incoming quantity and complete the reception by clicking the Validate option.

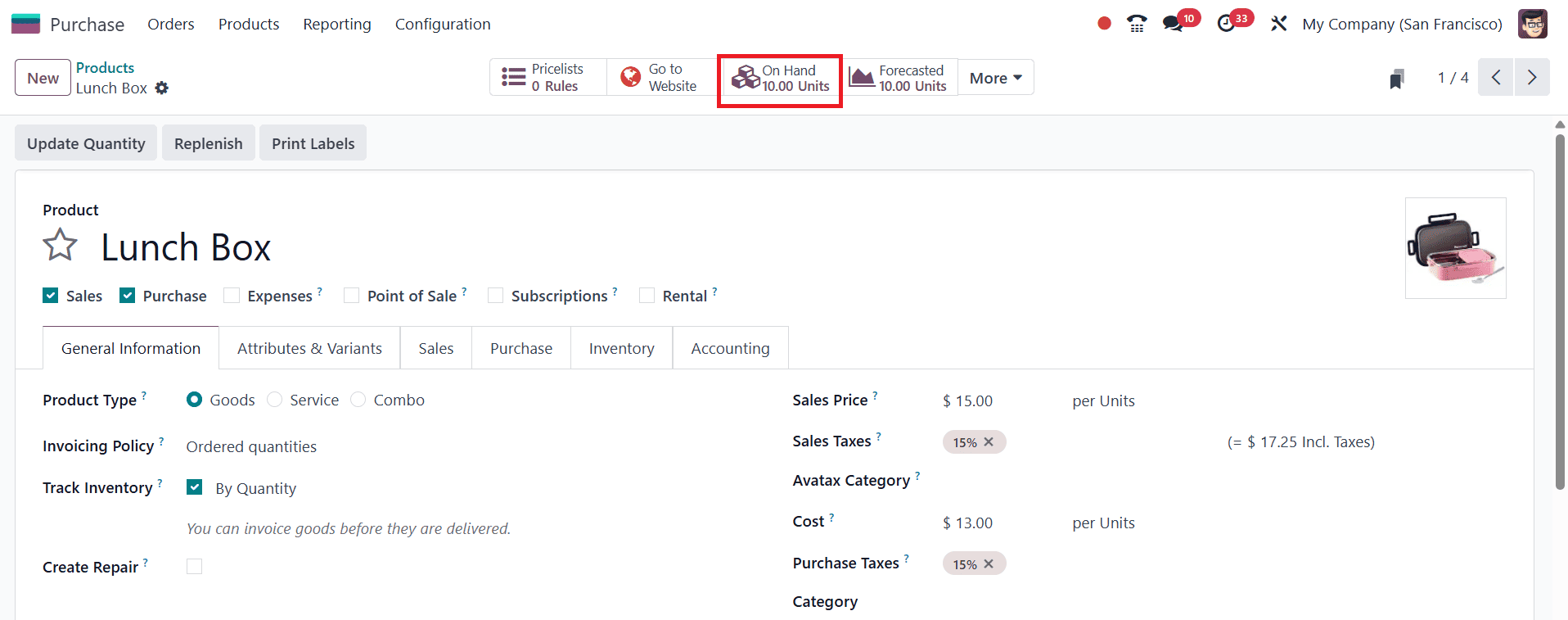

Once the product has been received and the receipt is validated, the On Hand quantity of the “Lunch Box” will be updated in real-time. You can verify this by checking the product's stock status in the Inventory module. You’ll now see the updated stock reflecting the replenished units.

You’ll now see the updated stock reflecting the replenished units.

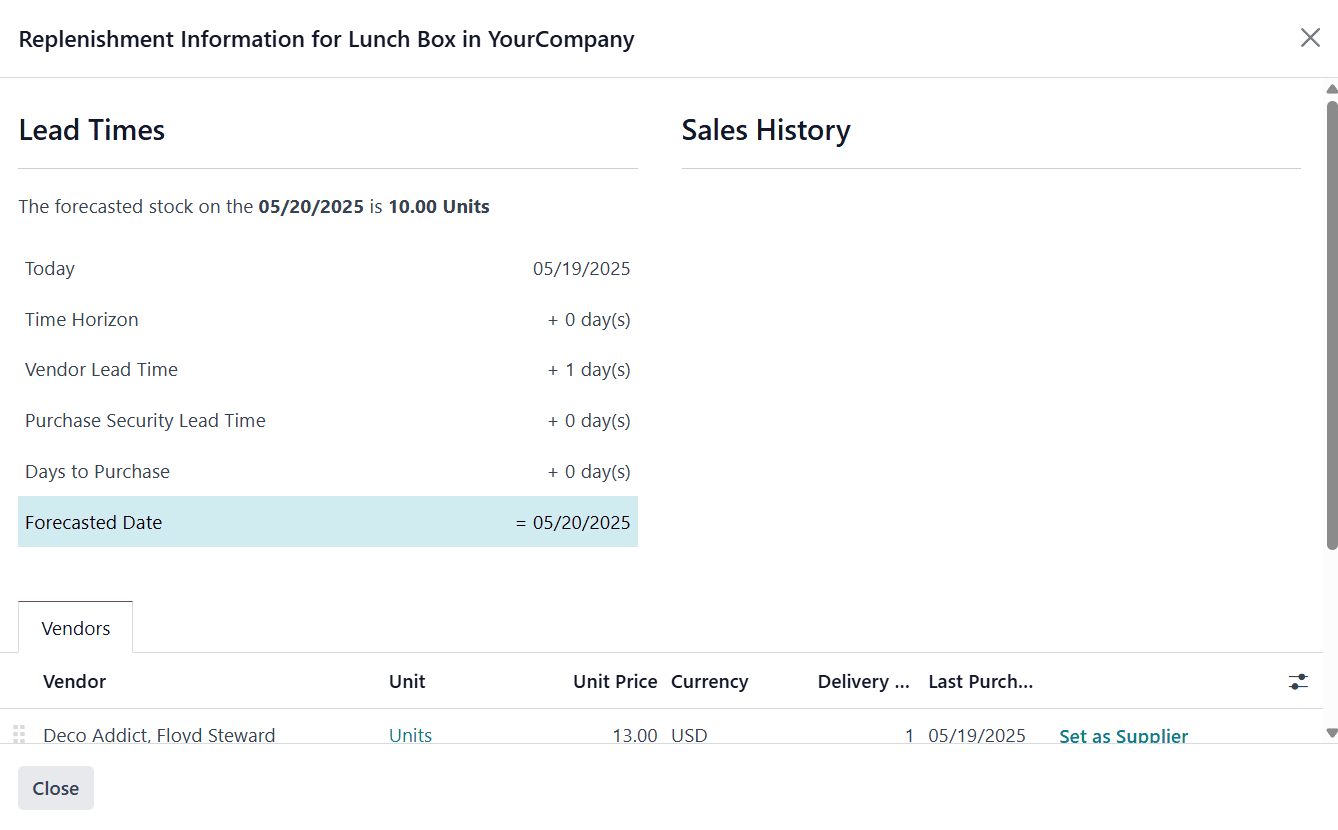

Clicking the info (??) icon in any line of the replenishment report opens a Replenishment Information pop-up window, where you can view the product’s lead times and forecasted replenishment date.

Horizon Days in Odoo help users plan replenishment in advance by specifying how many days ahead the system should check if the forecasted quantity will fall below the minimum set in the reordering rule. This ensures that Odoo can trigger replenishment early, even if the stock level is currently sufficient, but is expected to drop below the threshold within the defined period.

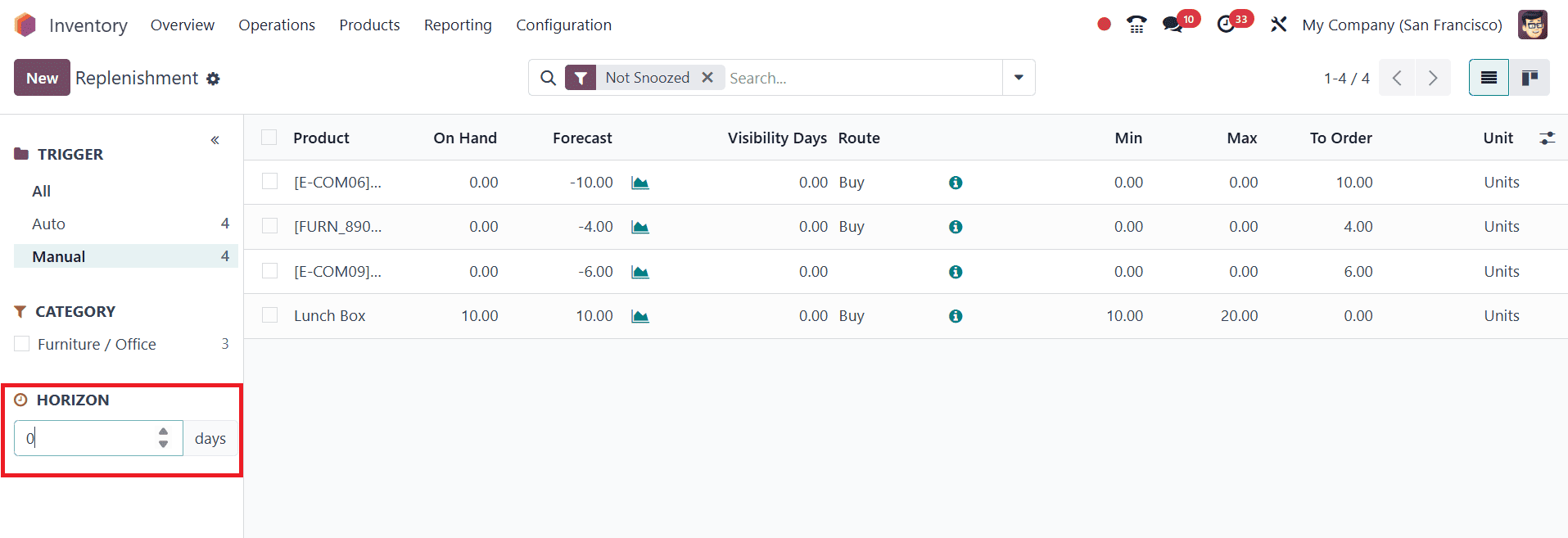

To configure Horizon Days, go to the Inventory app > Operations > Replenishment, and click Manual from the left sidebar.

In the menu that appears, set the desired number of Horizon Days. Once set, Odoo will automatically look ahead within that timeframe and apply the reordering rules accordingly, making sure you stay ahead of potential stockouts.

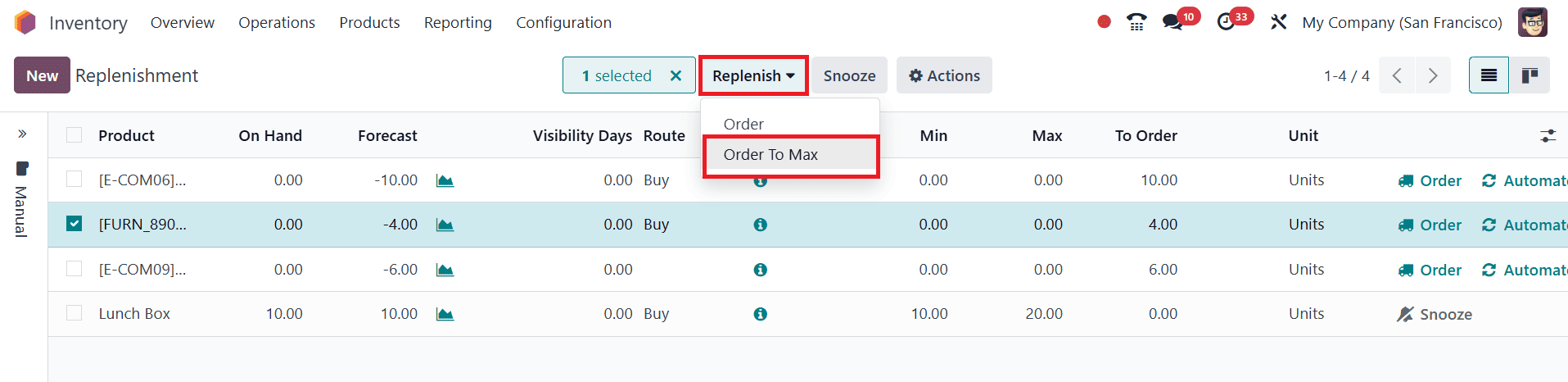

If a product’s forecasted stock does not fall below the minimum set in its reordering rule, Odoo won’t trigger replenishment automatically, as it considers it unnecessary. However, there are situations where replenishment may still be beneficial; for example, to maximize order quantity for bulk discounts or to reduce delivery costs by consolidating shipments.

In such cases, you can manually initiate replenishment. Simply select the desired products by ticking their checkboxes in the Replenishment Report, then click the Replenish button and choose Order to Max.

This action generates a Request for Quotation (RFQ) for each selected product, scheduling it for the earliest possible replenishment date and ordering the maximum quantity specified in the reordering rule.

The Replenishment Report in Odoo 18 Inventory offers a smart and efficient way to manage stock levels and avoid shortages or overstocking. By leveraging features like manual replenishment, automated rules, and flexible scheduling options, businesses can ensure smooth and timely inventory operations.

To read more about An Overview of the Replenishment Report in Odoo 17 Inventory, refer to our blog An Overview of Replenishment Report in Odoo 17 Inventory.